Microsoft Dynamics 365 Warehouse Management Module

Microsoft Dynamics 365 Supply Chain Management is a comprehensive solution designed to help businesses streamline their manufacturing processes. The Manufacturing module within Dynamics 365 offers a wide range of features and capabilities that enable organizations to manage their production operations effectively and efficiently. Here, we explore these features and capabilities in more detail:

-

Production Planning and Scheduling: Dynamics 365 Supply Chain Management provides robust production planning and scheduling tools, including master production scheduling (MPS), material requirements planning (MRP), and capacity planning. The module enables users to create and manage production orders, optimize resource allocation, and monitor work center capacities, ensuring efficient production processes and timely order fulfillment.

-

Bill of Materials (BOM) and Routing Management: The module offers advanced BOM and routing management capabilities, allowing organizations to define and maintain complex product structures, operations, and work center requirements. Users can create multi-level BOMs, manage revisions, and define routings for each operation, ensuring accurate production planning and cost estimation.

-

Shop Floor Control: Dynamics 365 Supply Chain Management provides shop floor control features, including work order management, work center scheduling, and real-time production monitoring. Users can track production progress, monitor machine utilization, and manage production exceptions, improving overall shop floor efficiency and visibility.

-

Lean Manufacturing: The module supports lean manufacturing principles and methodologies, such as Kanban, continuous improvement, and value stream mapping. Users can implement lean practices to reduce waste, improve production flow, and enhance overall manufacturing efficiency.

-

Quality Management: Dynamics 365 Supply Chain Management offers comprehensive quality management capabilities, enabling organizations to ensure product quality, compliance, and safety. Users can define quality tests, inspections, and sampling plans, as well as track quality data and generate quality reports, supporting compliance with industry-specific regulations and customer requirements.

-

Production Costing and Analysis: The module supports multiple costing methods, including standard cost, actual cost, and activity-based costing. Users can track and analyze production costs, monitor cost variances, and identify opportunities for cost reduction, ensuring accurate costing and improved profitability.

-

Integration with IoT and AI: Dynamics 365 Supply Chain Management integrates with Internet of Things (IoT) devices and leverages artificial intelligence (AI) technologies to provide real-time insights, predictions, and recommendations. This enables organizations to monitor equipment performance, optimize maintenance schedules, and improve overall operational efficiency.

-

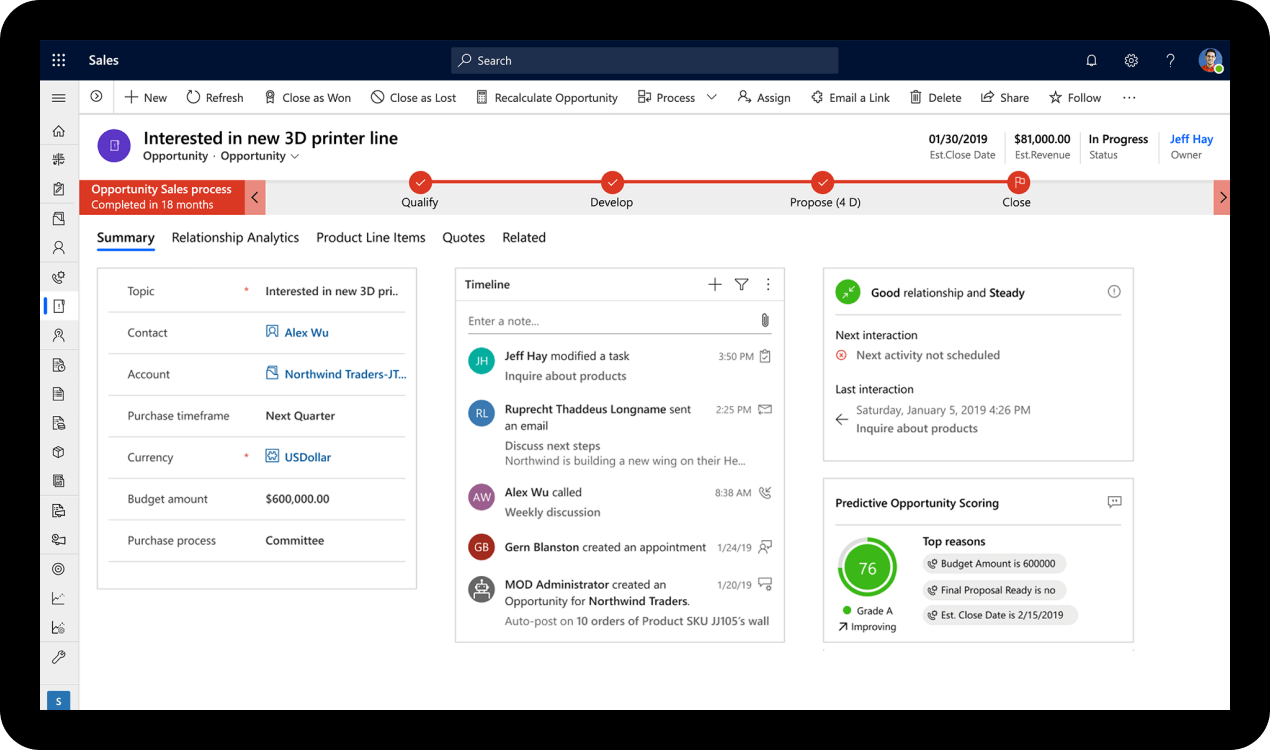

Collaboration and Communication: The module facilitates seamless communication and collaboration among production team members, including engineers, operators, and managers. It integrates with Microsoft Teams, SharePoint, and other collaboration tools, ensuring that everyone stays informed and engaged.

-

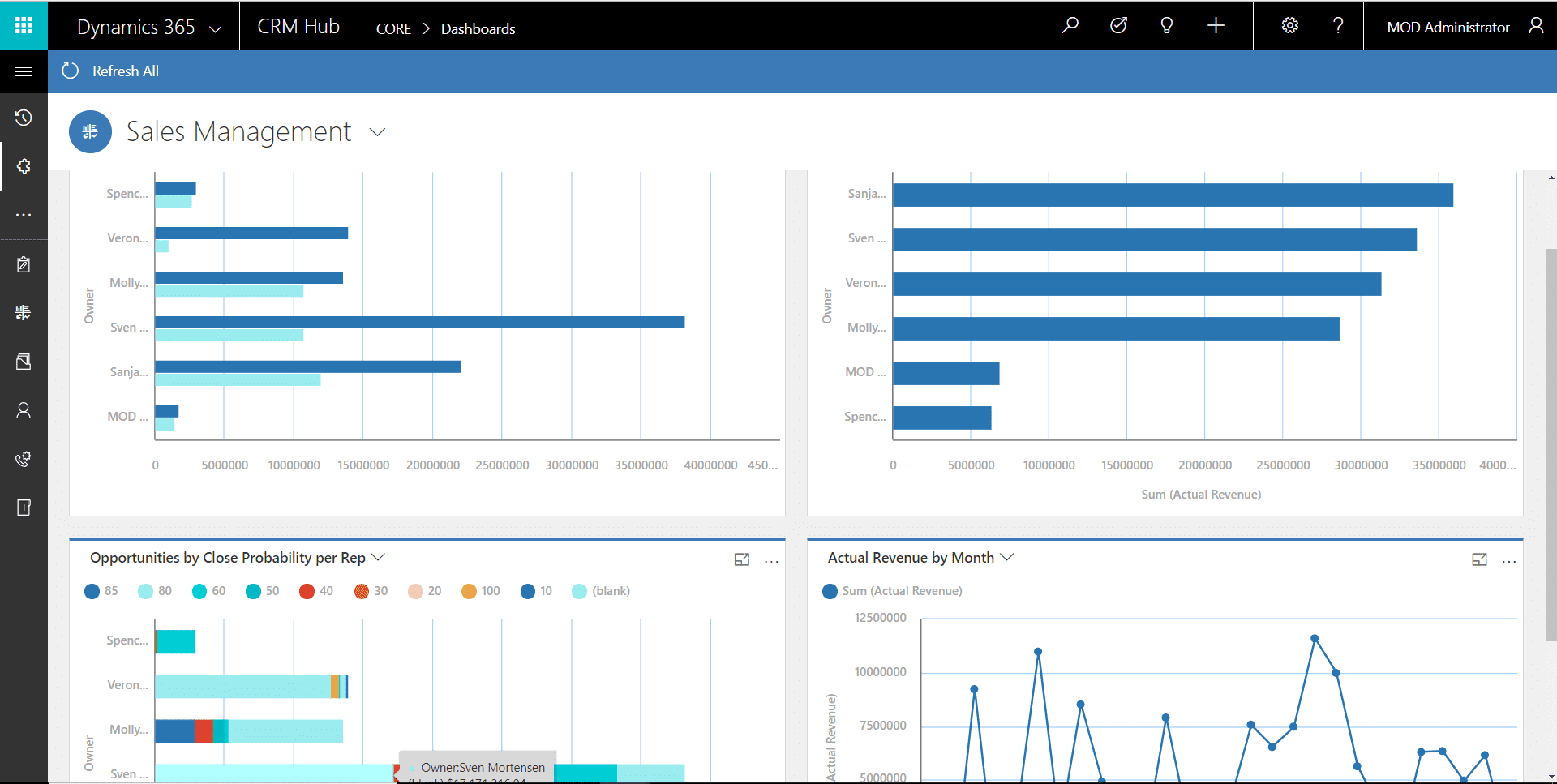

Reporting and Analytics: Dynamics 365 Supply Chain Management offers powerful reporting and analytics capabilities, providing real-time insights into manufacturing performance. Users can create custom reports, dashboards, and key performance indicators (KPIs) to monitor production metrics, such as efficiency, throughput, and quality. Integration with Power BI enhances the analytical capabilities, allowing for interactive data visualization and advanced reporting.

-

Compliance and Risk Management: The module provides tools and features to help organizations comply with industry-specific regulations, manage risks, and ensure product safety. It supports traceability, quality management, and audit trails, enabling businesses to maintain compliance with regulatory requirements and minimize production disruptions.

-

Integration and Extensibility: The Manufacturing module integrates seamlessly with other Dynamics 365 modules (such as Finance, Sales, and Customer Service), Microsoft products (e.g., Office 365 and Azure), and third-party applications, providing a unified experience across different business applications and enhancing the overall efficiency of the organization.

-

Scalability and Performance: Built on the Microsoft Azure cloud platform, Dynamics 365 Supply Chain Management offers organizations the scalability and performance they need to handle large volumes of production data and transactions. The module can easily scale up

or down as business requirements change, providing a flexible and cost-effective solution for managing manufacturing processes.

-

Mobility and Accessibility: Dynamics 365 Supply Chain Management offers a responsive, mobile-friendly user interface, allowing users to access the system from any device and location. With native mobile apps and a web-based interface, users can manage manufacturing tasks, access reports, and collaborate with stakeholders on-the-go, ensuring business continuity and improved productivity.

-

Environmental and Sustainability Management: The module supports environmental and sustainability initiatives, helping organizations track their energy consumption, waste generation, and emissions. Users can monitor the environmental impact of their manufacturing operations and implement strategies to reduce emissions, conserve resources, and minimize waste.

-

Product Lifecycle Management (PLM) Integration: Dynamics 365 Supply Chain Management integrates with PLM systems, enabling organizations to manage product information, engineering changes, and product development processes within a unified platform. This integration ensures seamless collaboration between design, engineering, and production teams, reducing time-to-market and improving product quality.