There are several options when it comes to considering the best ERP software for manufacturing and largely the answer will depend on several factors. In this article, we'll answer the following questions:

- What is the best ERP software for manufacturing?

- What is the best Cloud ERP for manufacturing?

- Which are the top ERP systems for manufacturers 2021?

- How do I compare manufacturing ERP software?

- How much does a manufacturing ERP system cost?

We'll also discuss some of the most popular ERP systems in the manufacturing space, including SAP, Oracle, Netsuite, Microsoft Dynamics, Odoo and many more.

If your manufacturing business is in the process of evaluating and getting ready for an ERP project, feel free to book a call with our team to help shortlist ERP software.

Alternatively, use our free ERP requirements template to kickstart your ERP for manufacturing evaluation process.

Contents:

1. ERP Modules for Manufacturing

2. Best ERP Systems for Manufacturing

- SME Manufacturing ERP Systems

- Hypergrowth & Large Manufacturing ERP Systems

3. How to choose ERP software for your manufacturing company

4. How to choose a Manufacturing ERP implementation partner

5. How much does a manufacturing ERP system cost?

Best ERP Systems for Manufacturing

What ERP systems do manufacturers use? Are there different ERP solutions for different types of manufacturing? Which ERP software is used by SMBs & SMEs?

Let's review manufacturing ERP software for different sizes of manufacturing companies and sub-industries:

Small & Medium-Sized (SME) Manufacturing ERP

Which are the best enterprise resource planning systems for small and mid-market manufacturing? What are the best Cloud ERP solutions for small manufacturers?

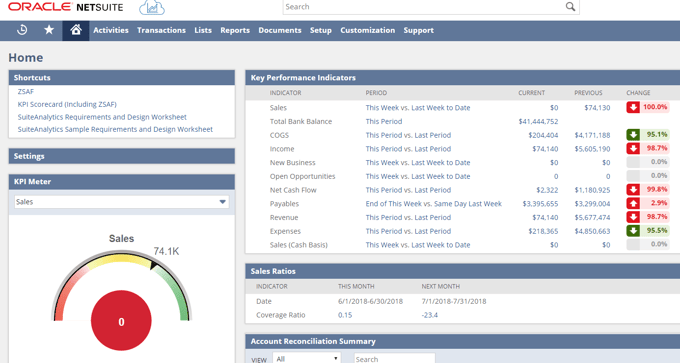

Oracle Netsuite is a common choice for small and medium SME & SMB manufacturers. Netsuite provides functionality for financial management & account, sales and marketing automation, supply chain and manufacturing in one software-as-a-service (Cloud) ERP tool. Manufacturing companies that are looking for a Cloud ERP software should look no further.

Find out more about Netsuite ERP for Manufacturing >>>

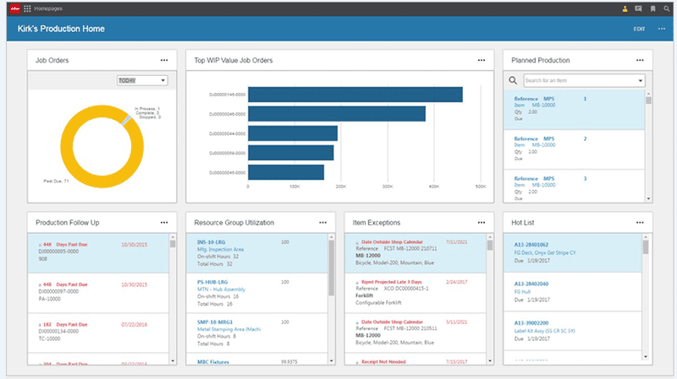

Infor CloudSuite Industrial, formally known as Infor Syteline is a strong ERP solution for companies in the SMB & SME manufacturing space. Syteline is used by manufacturers in several manufacturing subsectors including chemicals, pharmaceuticals, automotive, aerospace and defence and more.

Find out more about Infor CSI ERP for Manufacturing >>>

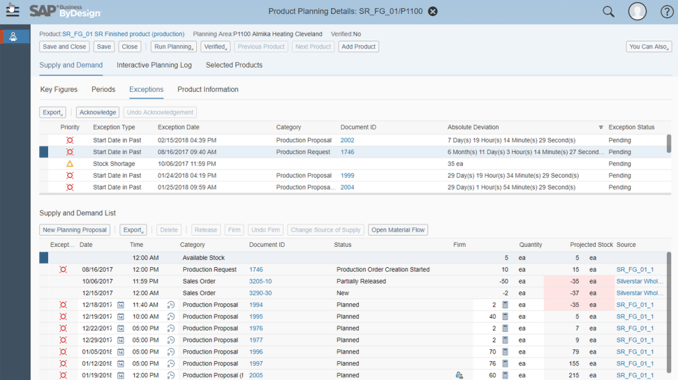

SAP Business ByDesign is a popular native Cloud ERP solution for manufacturing companies with as few as 50 employees. The solution offers more than 30 out-of-the-box business processes for manufacturing companies including lead to cash, procure to pay and other manufacturing specific business processes.

Manufacturers across various subindustries use SAP Business ByDesign, including food manufacturers, aerospace and defence, automotive and life sciences, pharmaceuticals and medical device manufacturers. ByDesign is one of the most popular Cloud ERP software for manufacturing.

Find out more about SAP Business ByDesign for Manufacturing >>>

Large Enterprise Manufacturing ERP

Which are the best enterprise resource planning systems for large, established or hypergrowth manufacturing companies?

Microsoft Dynamics 365 is one of the most popular ERP solutions for product centric and larger manufacturing companies. Dynamics also benefits manufacturers by having several other add-on modules and capabilities such as CRM, service as well as easy integration into the wider Microsoft product stack including Office 365.

SAP S/4 HANA is a strong ERP software for larger manufacturers. SAP S/4 HANA offers huge flexibility and scalability for manufacturing and is used by some of the worlds largest manufacturing companies across several industry verticals including automotive, high tech, pharmaceuticals and more.

Oracle ERP Cloud is the flagship ERP solution from the American software vendor, Oracle Corporation. In recent years Oracle has become more popular with manufacturing companies.

ERP Modules & Functionality for Manufacturing

What enterprise resource planning modules & capabilities are often needed by manufacturing companies? This will depend largely on the specific manufacturing subsector you work in and the type of manufacturing your company takes part in. The ERP needs of manufacturers in the food & beverage space will vary compared with those in the automotive or aerospace and defence industry for example.

Similiarly whether you are focused on discrete or process manufacturing, your needs will be largely different. With that said, here are some of the key capabilities we see companies in the manufacturing space demanding from their enterprise resource planning (ERP) software.

Finance & Accounting

Financial management and accounting is at the core of every ERP software solution and the same applies to manufacturing companies.

Inventory Management

The best ERP software for manufacturing provides robust inventory management and stock management capabilities, allowing your manufacturing company to monitor and get visibility of stock across multiple sites, physical and virtual warehouses.

Manufacturing & Production

Manufacturing ERP software wouldn't be complete without functionality, modules and capabilities for manufacturing and production. This includes modules for materials resource planning (MRP) and can also include integrated manufacturing execution systems (MES).

Supply Chain

Supply chain management (SCM) is key to every manufacturing ERP software. Being able to efficiently model and plan your supply chain ensures that your customers and suppliers can work in tandem with your forecasts, ensuring customer orders are delivered on time and product shortages don't impact your ability to deliver.

Procurement

Purchasing and procurement capabilities for manufacturing ERP typically include minimum reorder values, purchase order approval matrixes and more. It's key that manufacturing ERP software provides tightly integrated procurement and purchasing functionality to ensure that information is easily passed between other key functions including finance and manufacturing and production.

Quality Management

Quality management is a common requirement in manufacturing ERP software to be able to easily monitor the quality of your products and issues product recalls when neccesary.

Sales & Customer Relationship Management

Customer relationship management and sales is often an overlooked feature of manufacturing ERP software. However, passing important product specification data from your sales team to your backend manufacturing ERP system can be a tricky process which if done incorrectly can lead to issues.

We often find that manufacturing companies run separate, highly bespoke CRM and sales software that provides everything from lead and contact management through to opportunity and sales order creation. However once the deal is closed, integrating this data with your ERP and production software is very difficult.

Integrated CRM & ERP software for manufacturing solves this problem by integrating data at all points in the customer journey,

How to choose ERP software for your Manufacturing company?

With many ERP solutions out there for manufacturing, choosing one can be difficult. We recommend shortlisting anywhere from 4-8 manufacturing ERP software vendors and evaluating which one is the best fit for your requirements.

Step 1 - Build your ERP Requirements

Before you approach any manufacturing ERP vendor, its important to understand and to communicate your needs for your manufacturing ERP software. The best way to share these needs are by building an ERP Requirements document, which can be used for your ERP request for information (RFI) or RFP.

You can download our ERP requirements document for free here.

Choosing the best Manufacturing ERP Partner

When selecting any systems integrator or ERP implementation partner, it's worth understanding and quantifying their capabilities before signing contracts.

We highly recommend that you understand which companies your systems integrator or manufacturing ERP implementation partner has worked with in the past. If a company has several implementations under their belt, implementing ERP software that matches a similar scope of process and capabilities as you will need, it's likely they'll be successful with your implementation too.

It's also worth understanding their mixture of onshore and offshore resources. Companies that use a high level of offshore resources can often be cheaper, but sometimes this can compromise quality.

How much does Manufacturing ERP cost?

Manufacturing ERP implementations are generally broken down into three cost brackets. Costs can vary drastically depending on multiple factors but we'll provide some estimates below.

ERP Implementation Costs

These costs are incurred during the implementation phase of your chosen ERP software and are typically the largest capital expenditure during your ERP implementation process. This is the money you pay for the time of ERP consultants to work with your company to define and implement your chosen ERP software.

Although ERP implementation costs are typically a one-off outlay, it's rare that you'll simply upgrade your ERP systems and then wait another ten years before making another investment. ERP projects are typically continuous improvement projects and most companies will continue to invest every few years to gain greater efficiencies.

ERP implementations in the manufacturing space are generally more expensive than in people centric industries due to the depth and breadth of functionality that manufacturing companies can use in modern ERP systems. Costs therefore range from $100,000 to several millions depending on the complexity of your business.

ERP Licensing Costs

ERP software is usually either a capital or operating expenditure, depending on whether you choose to use Cloud or On-Premise software.

ERP software licensing can cost anywhere from a few hundred dollars per year per user to several thousand depending on the specific ERP software you choose and whether it is a Cloud or On-Premise solution.

ERP Support Costs

You can build an internal support team, but most companies choose to outsource the majority of their ERP support to the ERP vendor, systems integrator or a third party support partner.