Quality Management ERP

QMS software helps product centric companies including manufacturers, wholesalers and distributors to capture defects, improve quality and ensure compliance.

At ERP Research we help organizations of all types to find the quality management ERP software that meets their business requirements.

Top 10 ERP Software Report

Get our free in depth comparison of the Top 10 ERP solutions available on the market including Netsuite, Acumatica, Oracle, SAP and more.

Quality Management ERP Systems

Infor CloudSuite Industrial (Syteline)

Infor CSI is a popular ERP QMS solution for small and medium sized industrial companies including retail, wholesale, distribution and manufacturing companies.

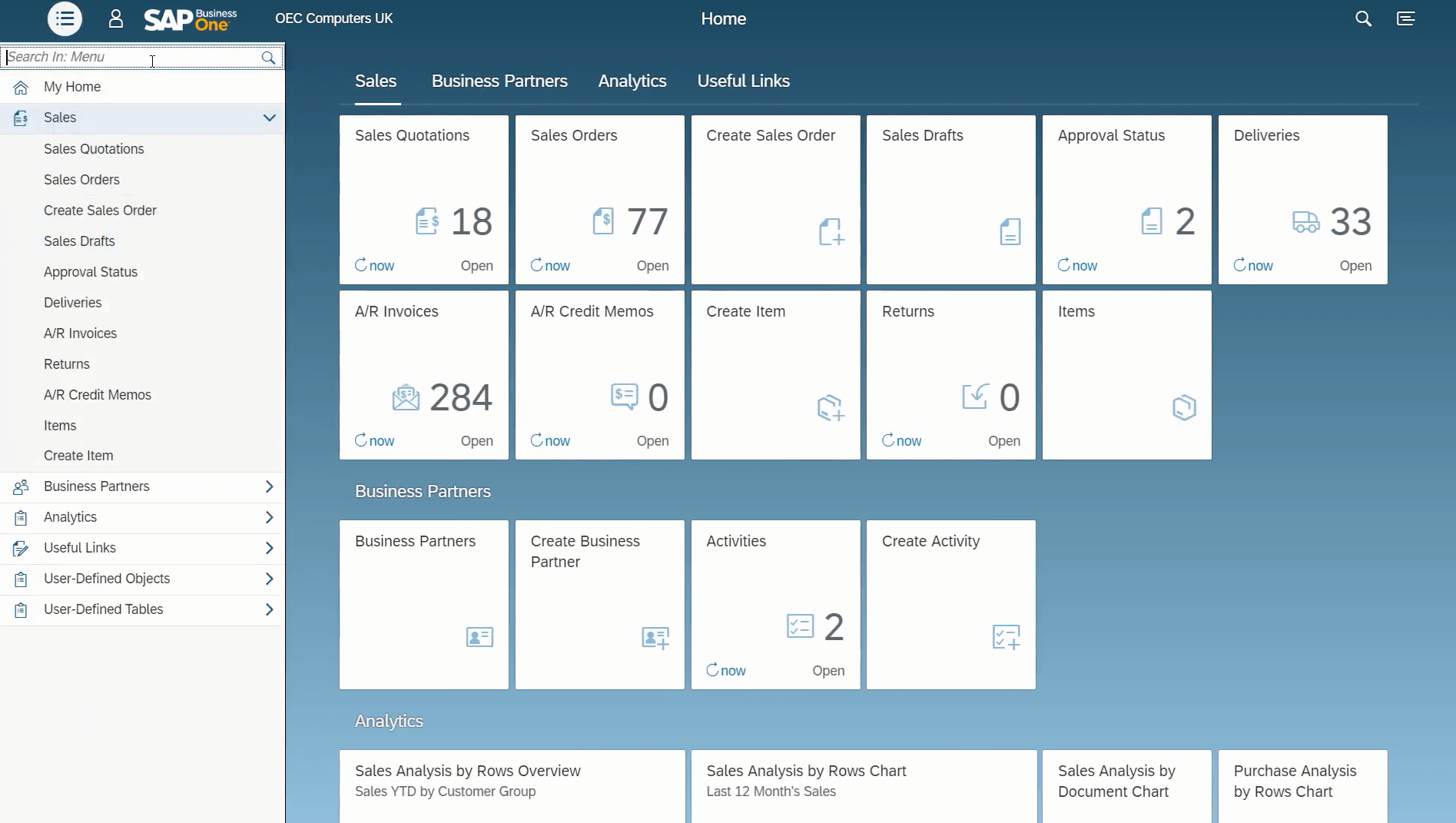

SAP Business One

SAP Business One is a popular ERP software for companies that need robust QMS capabilities and is used by some well known small and medium sized retailers and distribution companies.

Oracle Netsuite

NetSuite is an ERP that also includes warehouse management system capabilities. The QMS functionality of NetSuite enables businesses to manage defects and variations plus closely control documents within the system to remain compliant.

Odoo

Odoo is a powerful and versatile business management software that offers a range of essential features to streamline operations and enhance productivity. Among these features are its advanced warehouse management system (QMS) capabilities, which allow businesses to manage quality control procedures .

SAP Business ByDesign

SAP Business ByDesign's Quality Management ERP features are designed to streamline and optimize your quality operations. The ByDesign QMS system enables pharmaceutical companies, manufacturers and others to manage quality processes easily and compliantly.

Microsoft Dynamics Business Central

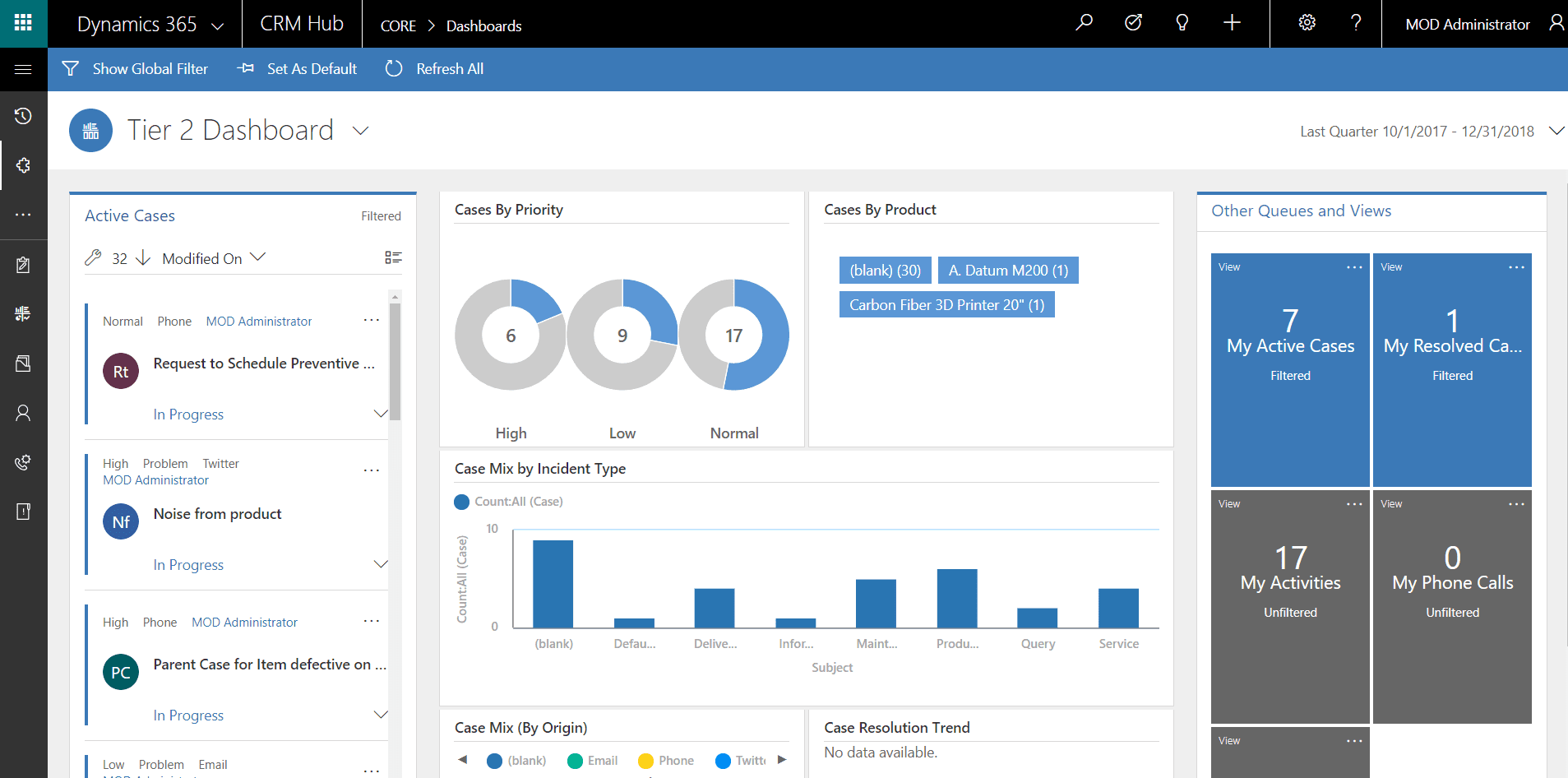

Microsoft Dynamics 365 is a powerful and comprehensive software solution that offers quality control functionalities for businesses of all sizes. With its advanced capabilities, Dynamics 365 enables organizations to streamline their quality control processes and ensure that they meet the highest standards of excellence.

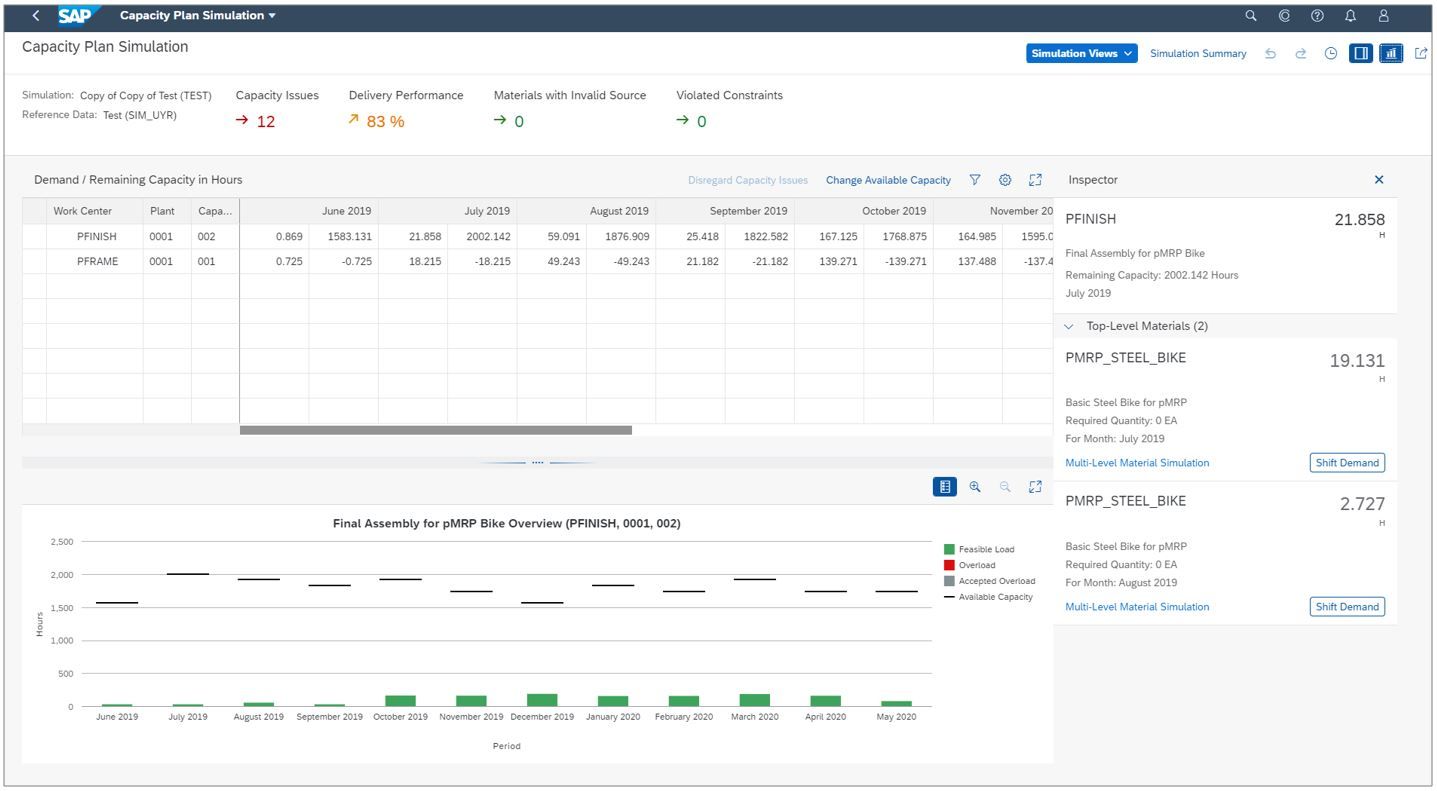

SAP S/4 HANA

SAP S/4 HANA offers a comprehensive set of Quality Management System (QMS) capabilities that enable organizations to streamline and optimize their quality processes. With SAP S/4 HANA QMS, companies can ensure compliance with industry standards and regulations, reduce the risk of product recalls, and enhance customer satisfaction.

Microsoft Dynamics 365

Microsoft Dynamics 365 offers a range of powerful tools to streamline warehouse management processes, and its Warehouse Management System (WMS) features are no exception. With Dynamics 365 WMS, you can easily manage inventory, track shipments, and optimize warehouse workflows in real-time.

Oracle ERP Cloud

Oracle ERP Cloud offers a comprehensive solution for quality management that streamlines processes and enhances visibility across the organization. With its robust set of tools and advanced analytics, organizations can easily track and manage quality issues, reduce costs, and improve customer satisfaction. From product design to delivery, Oracle ERP Cloud ensures that quality is at the forefront of every business decision.

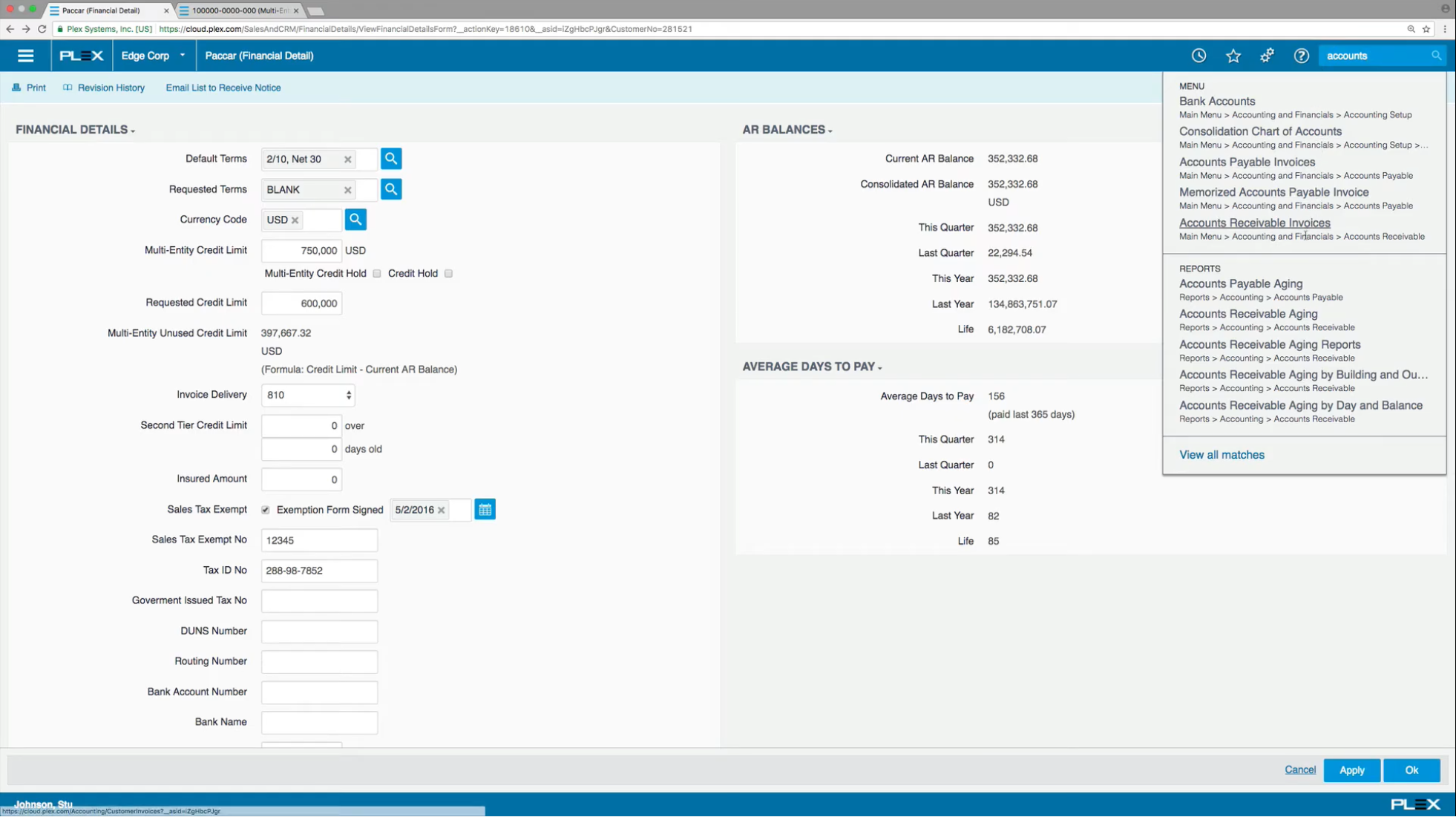

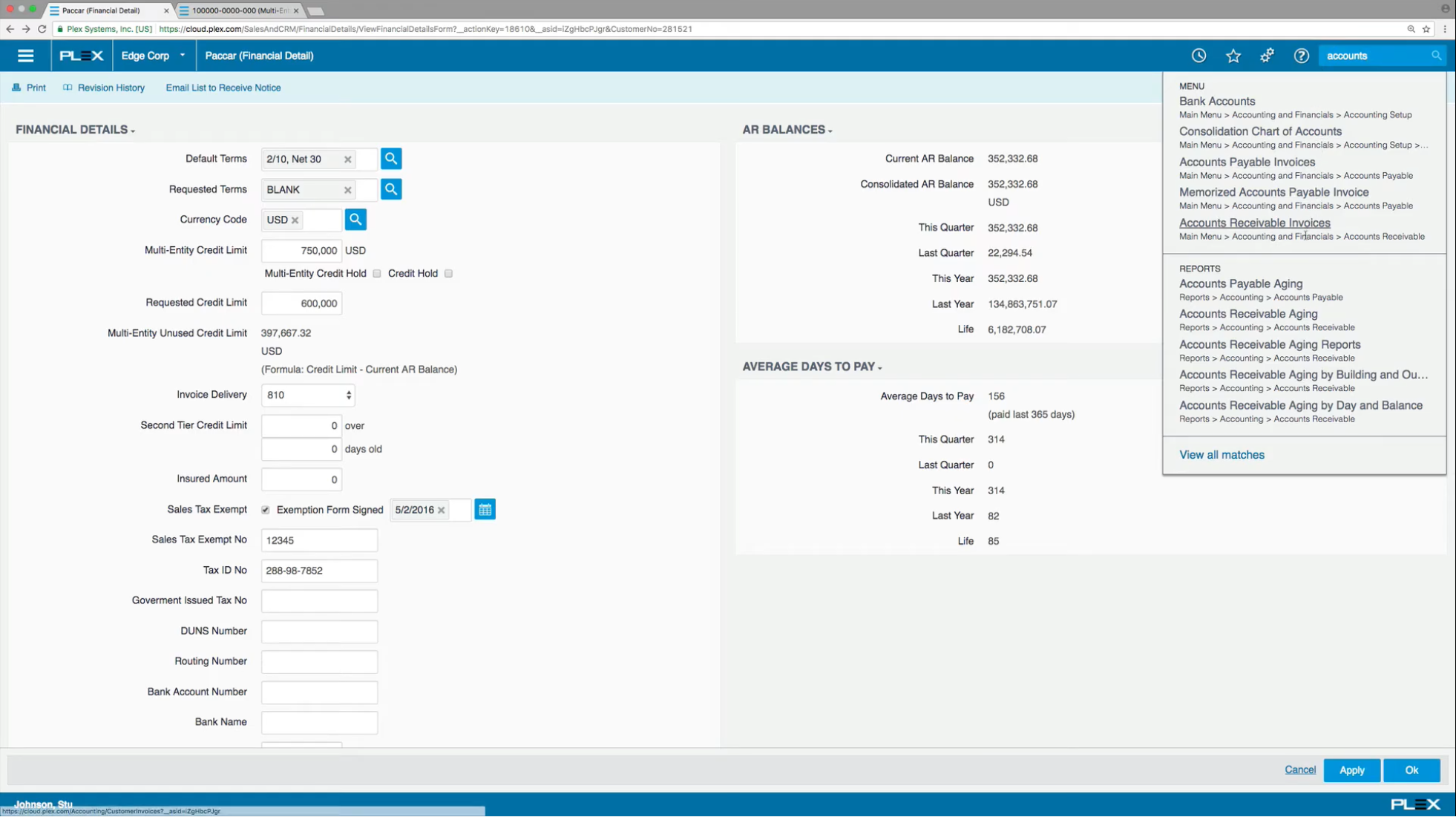

PLEX Manufacturing Cloud

Introducing PLEX Manufacturing Cloud for Quality. This innovative solution takes manufacturing to the next level by offering a comprehensive suite of tools that streamline the entire manufacturing process. With PLEX, manufacturers can easily manage their operations, from production to quality control, all in one place. The cloud-based platform provides real-time data and analytics, so you can make informed decisions that will drive your business forward.

IFS

IFS is a comprehensive enterprise resource planning (ERP) system that is ideal for managing quality across the entire organization. With IFS ERP, businesses can streamline quality management processes, including inspections, audits, and corrective actions. The system allows for real-time tracking of quality data, enabling businesses to identify and resolve quality issues quickly. IFS ERP also comes equipped with advanced analytics and reporting capabilities, giving businesses the insights they need to make data-driven decisions that support their quality management goals.

Acumatica

Acumatica is a popular enterprise resource planning (ERP) software that offers a wide range of features to help businesses manage their warehouse operations. With Acumatica, you can easily track inventory levels, monitor stock movements, and optimize your warehouse layout for maximum efficiency. The software also offers advanced features like barcode scanning, real-time data analytics, and automated replenishment to streamline your operations and reduce errors.

Cloud ERP WMS Software

Cloud ERP software for quality management needs integrated processes and data models to synchronise data between your internal business functions and simulate supply chains in real time. So here are some of the most popular quality management focussed Cloud ERP systems:

SAP S/4 HANA

SAP S/4 HANA is a next-generation enterprise resource planning (ERP) software that combines traditional transactional systems with advanced analytics and real-time data processing capabilities. With its simplified data model and user-friendly interface, it streamlines business processes and enables organizations to make data-driven decisions quickly and efficiently. As a Quality Management System (QMS) tool, SAP S/4 HANA offers enhanced functionality for quality planning, inspection, and control, ensuring compliance with industry standards and regulations.

Oracle ERP Cloud

Oracle ERP Cloud is a powerful solution for Quality Management Systems (QMS). It provides a comprehensive suite of tools to streamline and automate quality processes, including supplier management, non-conformance tracking, and corrective action management. With Oracle ERP Cloud, businesses can improve their quality and compliance efforts while reducing costs and enhancing operational efficiency.

SAP Business ByDesign

SAP Business ByDesign is an all-in-one cloud-based business software solution that can help streamline your quality control processes. With its integrated analytics and reporting capabilities, you can gain real-time visibility into your quality data and identify areas for improvement. The system also offers configurable workflows and automated alerts to ensure that quality control procedures are followed consistently throughout your organization.

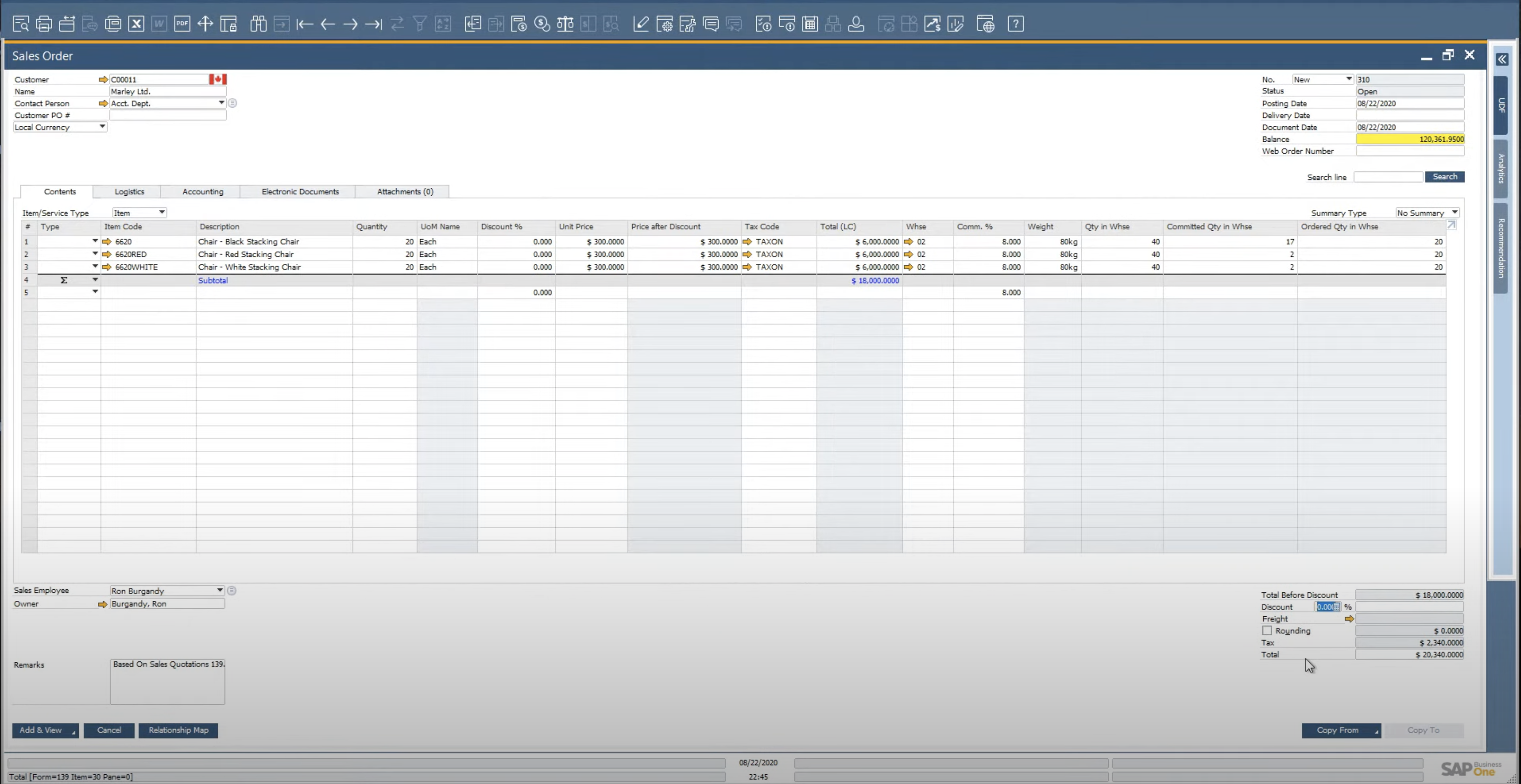

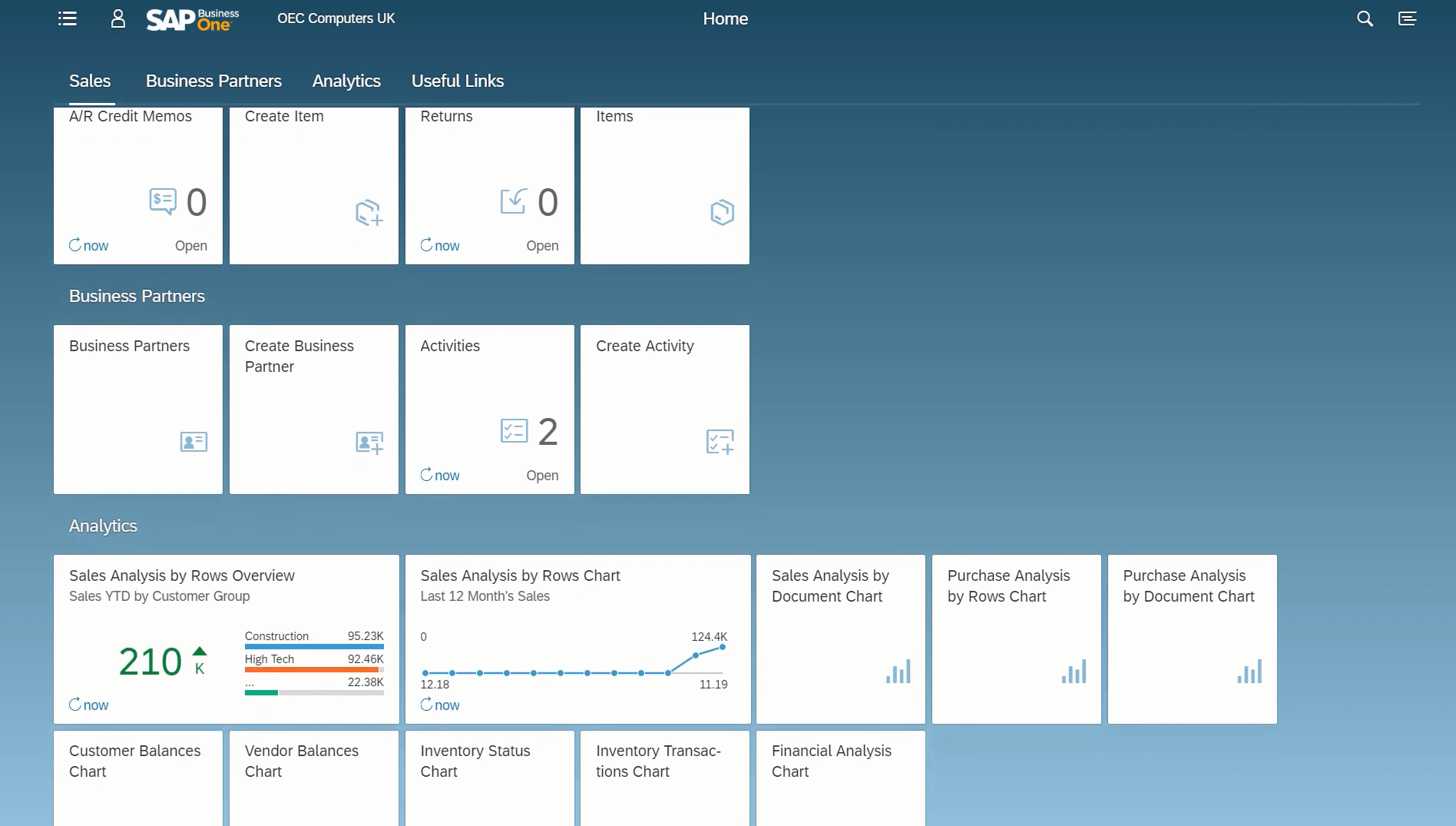

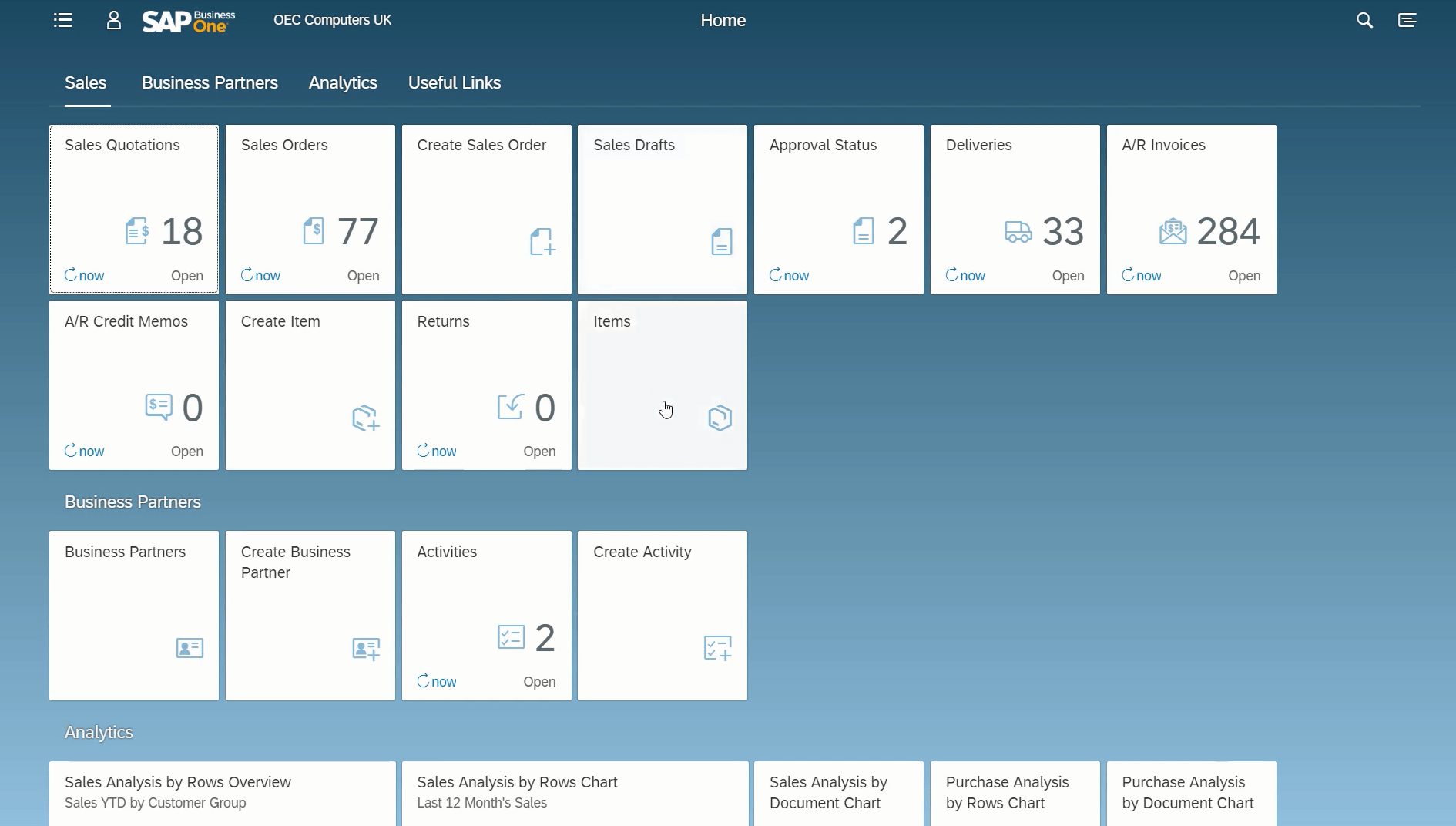

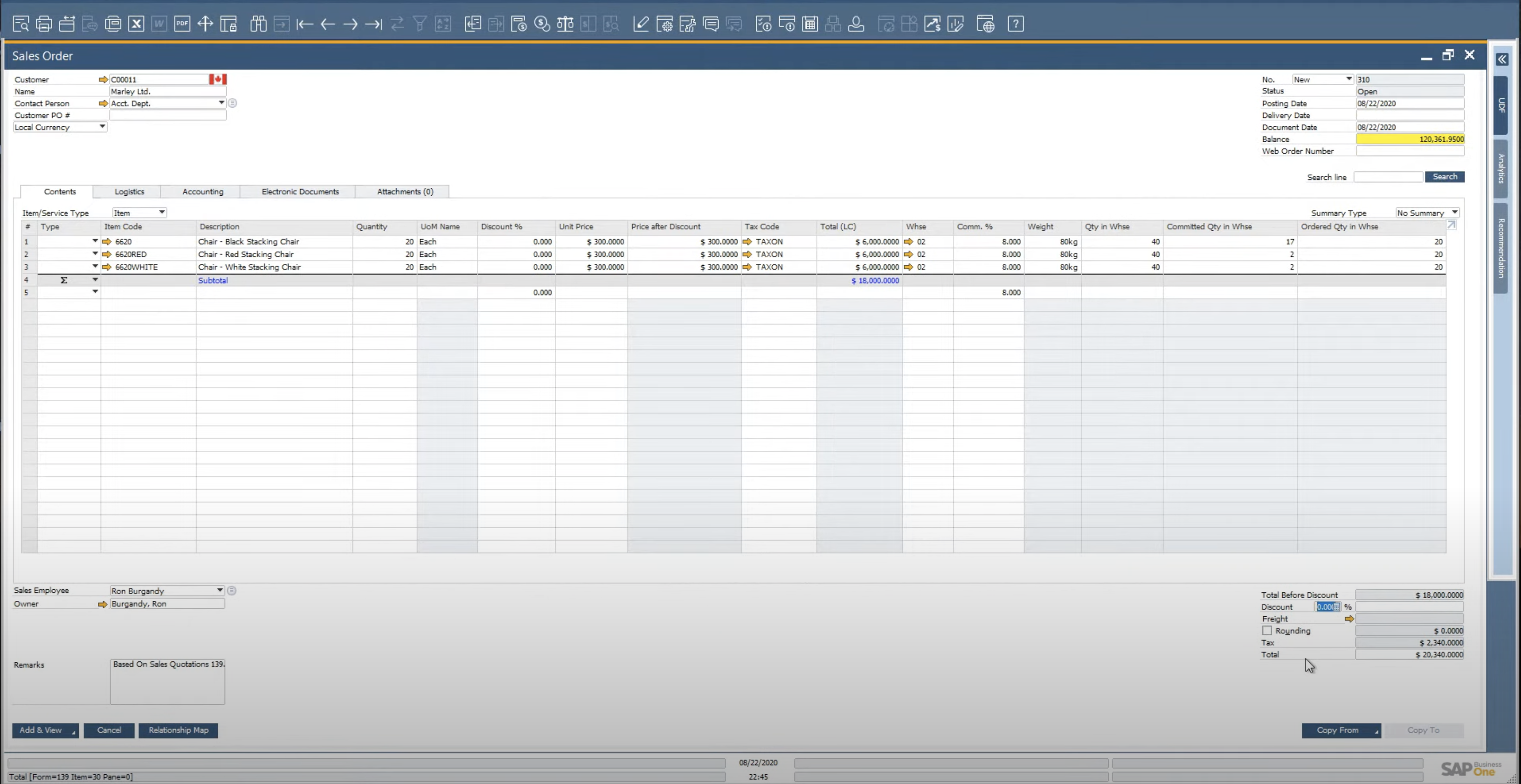

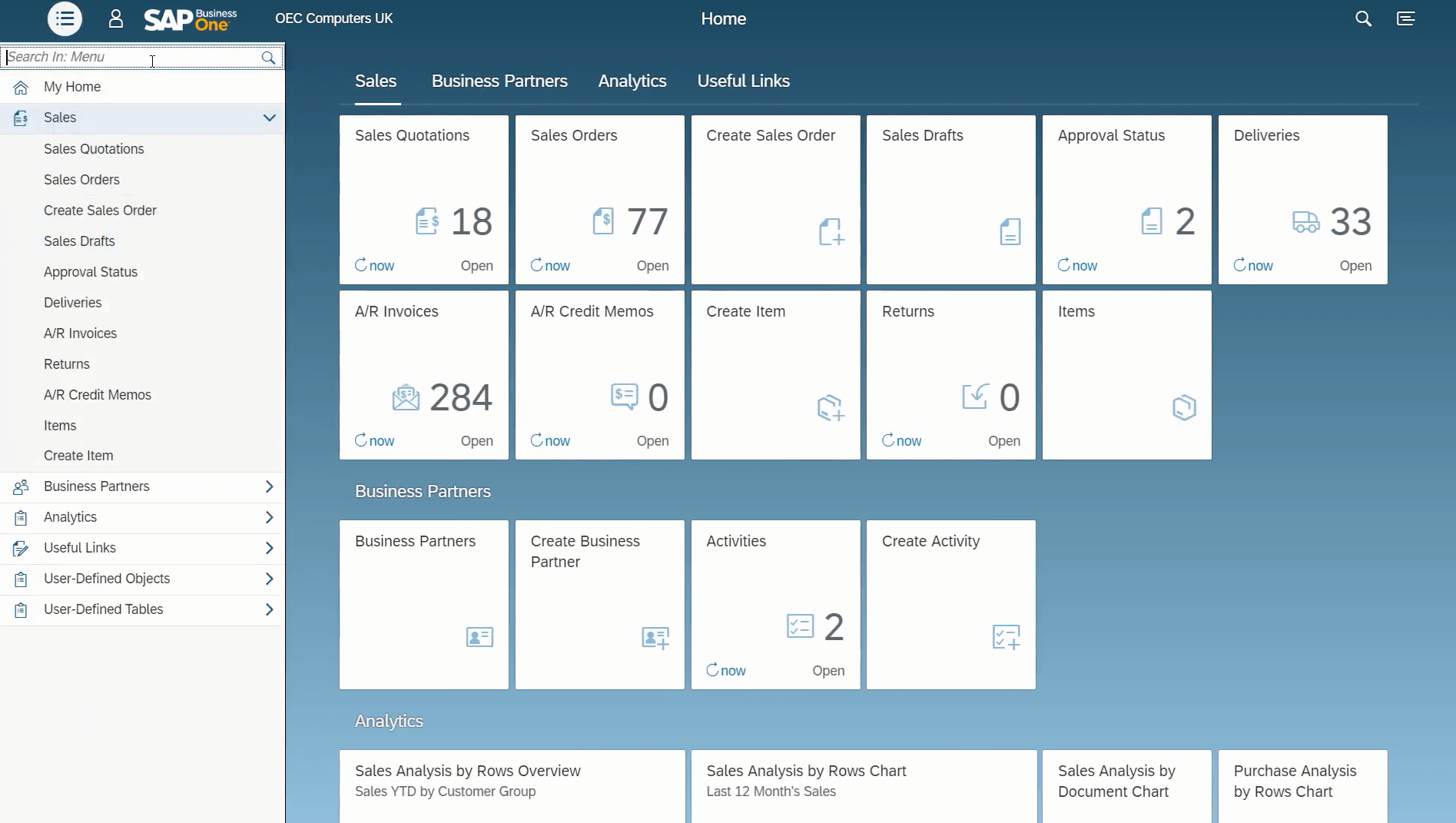

SAP Business One

SAP Business One is a comprehensive enterprise resource planning (ERP) software solution designed specifically for small and medium-sized businesses (SMBs). It provides a complete suite of tools that help businesses streamline their operations, automate key processes, and make better decisions based on real-time data. With its powerful functionality and ease of use, SAP Business One is trusted by thousands of companies worldwide.

One of the key benefits of SAP Business One is its ability to function as a quality management ERP. With its advanced quality management tools, businesses can track and manage quality-related information, including managing quality control processes, tracking product quality and defects, and managing quality-related documents. Additionally, SAP Business One also enables businesses to implement quality control checks throughout the entire supply chain, helping to ensure that all products meet the required quality standards.

In addition to its quality management capabilities, SAP Business One also offers a wide range of other features that can help businesses improve their operations. These include financial management tools, inventory and warehouse management, sales and customer management, purchasing and supplier management, and more. And with its customizable functionality, businesses can tailor SAP Business One to meet their specific needs, ensuring that they get the most out of their investment in the software.

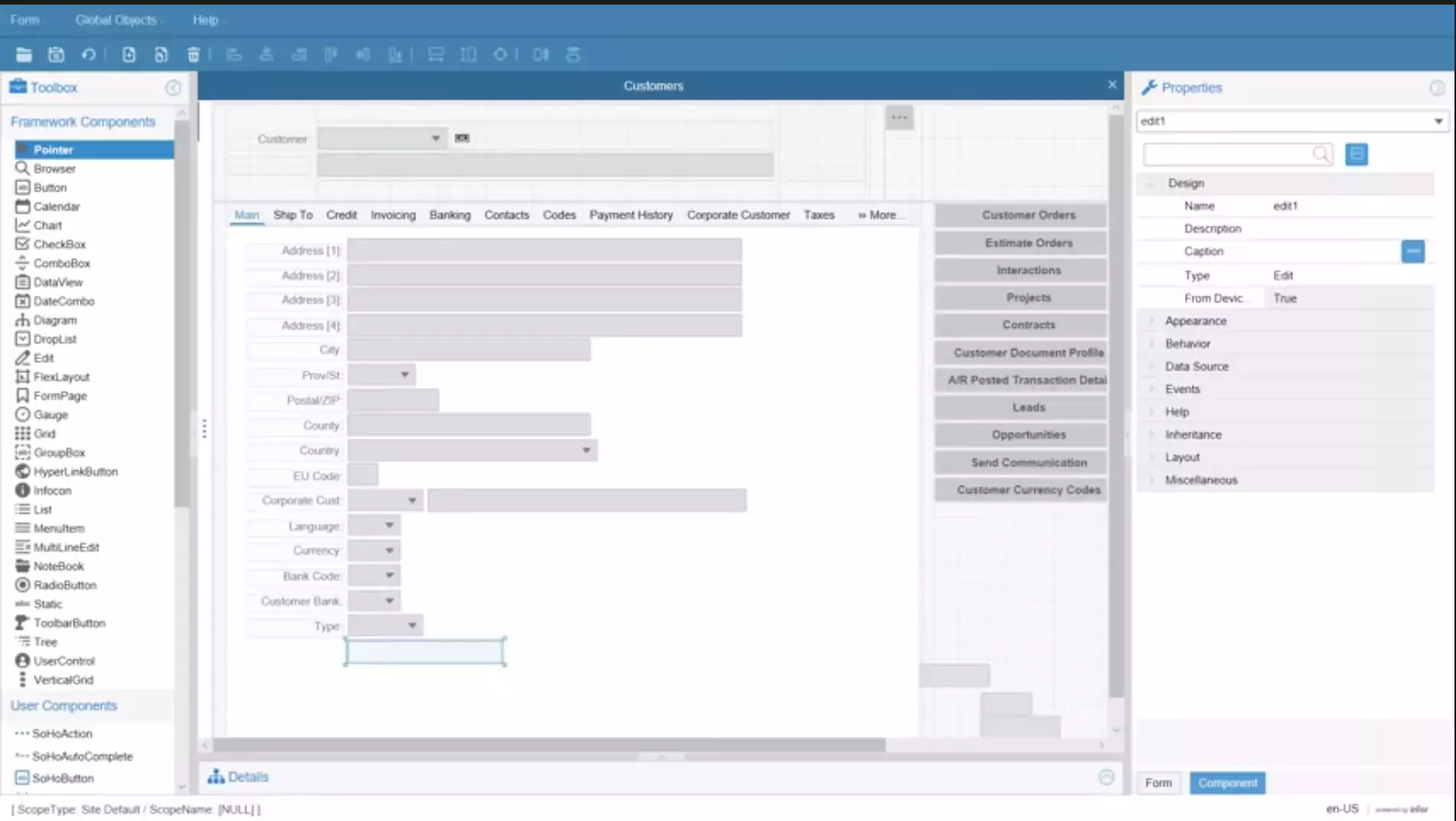

Infor CloudSuite Industrial

Infor CloudSuite Industrial (formerly known as SyteLine) is an Enterprise Resource Planning (ERP) software designed specifically for manufacturers. It offers a suite of applications to manage various aspects of manufacturing operations, including production planning, scheduling, inventory management, supply chain management, and financial management.

In addition to these core functionalities, Infor CloudSuite Industrial also includes modules for Quality Management, which can be used to support a quality management system (QMS). The QMS module can help companies manage quality processes, track and analyze quality data, and comply with industry regulations and standards such as ISO 9001.

Here are some of the ways in which Infor CloudSuite Industrial can be used as a quality management ERP:

-

Document Control: The software allows you to control all your quality-related documents, including work instructions, standard operating procedures (SOPs), and quality manuals. You can store, manage, and track all documents, ensuring that the latest versions are always available to users.

-

Non-conformance Management: Infor CloudSuite Industrial can help you manage non-conformance issues and identify the root cause of quality problems. You can set up workflows to manage the investigation and resolution of non-conformance issues, ensuring that corrective actions are taken promptly.

-

Corrective and Preventive Action (CAPA) Management: The software can be used to manage the CAPA process, including the identification of issues, investigation, root cause analysis, corrective actions, and verification of effectiveness. This can help you continuously improve your quality processes and prevent similar issues from occurring in the future.

-

Audit Management: Infor CloudSuite Industrial can help you manage internal and external audits by providing tools for planning, scheduling, conducting, and following up on audit activities. You can also track and report on audit findings, ensuring that corrective actions are taken promptly.

-

Quality Reporting and Analytics: Infor CloudSuite Industrial provides real-time visibility into quality metrics, allowing you to track and analyze quality data. You can create customized reports and dashboards to monitor quality performance, identify trends, and make data-driven decisions.

SAP S/4 HANA

SAP S/4HANA is a modern, fully integrated enterprise resource planning (ERP) software that provides a wide range of functionality for managing different business processes, including quality management (QM). As a QM ERP, SAP S/4HANA offers several features and capabilities that allow organizations to improve their quality management practices and ensure compliance with industry standards.

Here are some of the ways SAP S/4HANA can be used as a quality management ERP:

-

Quality Planning: SAP S/4HANA's QM module allows users to create quality plans that define the quality standards, specifications, and control procedures for different products or processes. These plans can be linked to other modules such as materials management (MM) or production planning (PP) to ensure that quality requirements are met at every stage of the production process.

-

Quality Inspection: SAP S/4HANA's QM module enables users to perform quality inspections at various stages of the production process, from raw materials to finished goods. Inspection results can be recorded in the system and used to track quality trends over time, identify defects, and take corrective actions.

-

Non-Conformance Management: SAP S/4HANA's QM module provides tools for managing non-conformances, such as defects or deviations from quality standards. The system can automatically trigger notifications and workflows to ensure that non-conformances are addressed promptly and effectively.

-

Supplier Quality Management: SAP S/4HANA's QM module enables organizations to manage the quality of their suppliers by tracking their performance, conducting audits, and managing corrective actions. This can help organizations to ensure that their suppliers meet their quality standards and reduce the risk of quality-related issues.

-

Analytics and Reporting: SAP S/4HANA provides a range of analytics and reporting tools that allow users to monitor quality metrics, track trends, and identify areas for improvement. These insights can be used to optimize quality management processes and ensure compliance with regulatory requirements.

Acumatica

Acumatica, a cloud-based Enterprise Resource Planning (ERP) system, can be effectively utilized as a Quality Management System (QMS) ERP for businesses to streamline their quality control and assurance processes. While Acumatica does not have a built-in QMS module, businesses can integrate third-party QMS solutions or create customized modules to address their specific quality management needs. Here's how Acumatica can be used as a QMS ERP:

-

Integration with third-party QMS solutions: Acumatica's flexible architecture allows seamless integration with various third-party QMS solutions, enabling businesses to leverage the best QMS tools that suit their unique requirements. Integrating a QMS solution with Acumatica provides a centralized platform for managing quality-related activities alongside other critical business processes.

-

Customization and development: Acumatica's robust customization capabilities enable businesses to create their own QMS modules tailored to their specific needs. These custom modules can encompass various aspects of quality management, such as quality planning, control, assurance, and improvement.

-

Document management: Acumatica's document management capabilities allow businesses to store, manage, and track quality-related documents, such as policies, procedures, work instructions, and records. This ensures easy access to the latest documentation, promoting consistency and compliance with relevant standards.

-

Process automation: Acumatica's workflow automation features can help streamline quality management processes by automating tasks, such as notifications, approvals, and escalations. This reduces the chances of human error, increases efficiency, and ensures timely completion of quality-related activities.

-

Compliance and traceability: Acumatica enables businesses to maintain detailed records of quality-related activities, such as inspections, audits, and corrective actions, providing complete traceability and accountability. This information is crucial for meeting regulatory requirements and demonstrating compliance to various quality standards, such as ISO 9001, FDA, and GMP.

-

Real-time visibility and reporting: Acumatica's analytics and reporting capabilities provide real-time insights into quality performance, allowing businesses to monitor key quality metrics and identify trends. This helps organizations make informed decisions and take proactive measures to improve their quality management processes.

-

Collaboration and communication: Acumatica's centralized platform facilitates effective communication and collaboration among team members involved in quality management activities. This promotes a culture of quality and helps in the quick resolution of issues.

-

Integration with other ERP modules: Acumatica's QMS can be integrated with other ERP modules, such as production, procurement, inventory management, and sales, to ensure quality throughout the entire product lifecycle. This helps businesses maintain consistent quality standards and meet customer expectations.

Plex Manufacturing Cloud

Plex Manufacturing Cloud is a cloud-based Enterprise Resource Planning (ERP) solution specifically designed for manufacturers. It provides a comprehensive suite of tools and applications that enable businesses to streamline their manufacturing processes, optimize their supply chain, and improve overall efficiency. One of the key aspects of the Plex Manufacturing Cloud is its quality management capabilities, which can be leveraged to enhance product quality, ensure compliance with industry standards, and reduce waste.

Here's how Plex Manufacturing Cloud can be used as a quality management ERP system:

-

Centralized data management: Plex Manufacturing Cloud consolidates all the essential data related to quality management in one place, making it easier for manufacturers to access, analyze, and share information. This ensures that all stakeholders have access to accurate and up-to-date data, enabling them to make informed decisions and quickly respond to issues.

-

Process automation: Plex Manufacturing Cloud automates various quality management processes, such as inspection, testing, and data collection. This helps reduce human error, save time, and ensure consistency in quality control procedures. Furthermore, automation can help in the timely detection of quality issues, allowing manufacturers to address them proactively.

-

Real-time monitoring: The system allows for real-time monitoring of production processes, equipment, and product quality, providing manufacturers with the information they need to identify potential issues and make data-driven decisions. By leveraging real-time data, manufacturers can more effectively optimize their production processes and improve overall product quality.

-

Compliance management: Plex Manufacturing Cloud helps manufacturers ensure compliance with industry standards and regulations by providing tools to manage and track certifications, audits, and other compliance-related activities. The system also maintains a comprehensive record of all quality and compliance data, making it easy for manufacturers to generate reports and demonstrate compliance when required.

-

Traceability and genealogy: The platform offers end-to-end traceability of products, components, and materials throughout the supply chain. This level of traceability enables manufacturers to quickly identify the root cause of any quality issues, initiate corrective actions, and minimize the impact of recalls or defects on their operations and reputation.

-

Non-conformance and corrective action management: Plex Manufacturing Cloud provides tools for managing non-conformances and implementing corrective and preventive actions. By documenting and analyzing non-conformances, manufacturers can identify trends, prioritize improvements, and prevent recurring issues, ultimately improving product quality and reducing waste.

-

Supplier quality management: The system allows manufacturers to assess and manage the performance of suppliers, ensuring that they meet the required quality standards. This helps to reduce the risk of supply chain disruptions and maintain consistent product quality.

-

Document control: Plex Manufacturing Cloud enables efficient management of all quality-related documents, such as Standard Operating Procedures (SOPs), work instructions, and inspection plans. This ensures that employees have access to the most up-to-date information, promoting adherence to best practices and reducing the risk of fines and deviations.

Microsoft Dynamics 365

Microsoft Dynamics 365 is a suite of cloud-based Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM) applications designed to help businesses streamline their operations, enhance customer experiences, and make data-driven decisions. One of the essential components of Dynamics 365 is its quality management capabilities, which can be leveraged to improve product quality, ensure compliance with industry standards, and reduce waste.

Here's how Microsoft Dynamics 365 can be used as a quality management ERP system:

-

Centralized data management: Dynamics 365 consolidates all essential data related to quality management in a single platform, making it easier for businesses to access, analyze, and share information. This ensures that all stakeholders have access to accurate and up-to-date data, enabling them to make informed decisions and quickly respond to issues.

-

Process automation: Dynamics 365 can automate various quality management processes, such as inspection, testing, and data collection. This helps reduce human error, save time, and ensure consistency in quality control procedures. Moreover, automation can help in the timely detection of quality issues, allowing businesses to address them proactively.

-

Real-time monitoring: The system allows for real-time monitoring of production processes, equipment, and product quality, providing businesses with the information they need to identify potential issues and make data-driven decisions. By leveraging real-time data, companies can more effectively optimize their production processes and improve overall product quality.

-

Compliance management: Dynamics 365 helps businesses ensure compliance with industry standards and regulations by providing tools to manage and track certifications, audits, and other compliance-related activities. The system also maintains a comprehensive record of all quality and compliance data, making it easy for businesses to generate reports and demonstrate compliance when required.

-

Traceability and genealogy: The platform offers end-to-end traceability of products, components, and materials throughout the supply chain. This level of traceability enables businesses to quickly identify the root cause of any quality issues, initiate corrective actions, and minimize the impact of recalls or defects on their operations and reputation.

-

Non-conformance and corrective action management: Dynamics 365 provides tools for managing non-conformances and implementing corrective and preventive actions. By documenting and analyzing non-conformances, businesses can identify trends, prioritize improvements, and prevent recurring issues, ultimately improving product quality and reducing waste.

-

Supplier quality management: The system allows businesses to assess and manage the performance of suppliers, ensuring that they meet the required quality standards. This helps to reduce the risk of supply chain disruptions and maintain consistent product quality.

-

Document control: Dynamics 365 enables efficient management of all quality-related documents, such as Standard Operating Procedures (SOPs), work instructions, and inspection plans.

ERP QMS Systems Compared

| ERP System | Cost | Modules | Quality Management Capabilities | Deployment | Business Size | Number of Customers |

|---|---|---|---|---|---|---|

| SAP S/4 HANA | High | Finance, Supply Chain, Sales & Distribution, Manufacturing, Procurement, Asset Management, Project Management, HR | Advanced quality planning, Product testing, Quality inspections, Supplier quality management | On-premise, Cloud | Large enterprises | 14,000+ |

| Microsoft Dynamics 365 | High | Finance & Operations, Sales, Customer Service, Field Service, Project Service Automation, Supply Chain Management, HR | Quality control, Quality assurance, Product testing | On-premise, Cloud | Small to large enterprises | 365,000+ |

| QAD ERP | High | Financials, Manufacturing, Supply Chain, Sales & Marketing | Quality management, Quality inspections, Supplier quality management | On-premise, Cloud | Small to large enterprises | 1,100+ |

| Acumatica | Medium | Financial Management, Distribution Management, Project Accounting, CRM, Manufacturing, Field Service, eCommerce, Construction | Quality control, Quality assurance, Product testing, Supplier quality management | Cloud | Small to medium-sized enterprises | 6,500+ |

| Plex Manufacturing Cloud | High | Financial Management, Production Management, Supply Chain Management, Quality Management, MES | Quality control, Quality assurance, Supplier quality management | Cloud | Small to medium-sized enterprises | 700+ |

| SAP Business ByDesign | Medium | Financial Management, Supply Chain Management, Project Management, CRM, HR | Quality management, Quality inspections, Supplier quality management | Cloud | Small to medium-sized enterprises | 6,500+ |

| DELMIAWORKS | High | Financial Management, Supply Chain Management, Manufacturing Management, Quality Management | Quality planning, Quality control, Quality assurance, Supplier quality management | On-premise, Cloud | Small to large enterprises | 2,000+ |

| SYSPRO | Medium | Financial Management, Inventory Management, Production Planning & Scheduling, Sales & CRM, Supply Chain Management, Quality Management | Quality control, Quality assurance, Supplier quality management | On-premise, Cloud | Small to medium-sized enterprises | 15,000+ |

| Infor CloudSuite Industrial | High | Financials, Supply Chain Management, Production Management, Quality Management, Asset Management | Quality control, Quality assurance, Supplier quality management | On-premise, Cloud | Small to large enterprises | 1,200+ |

| SAP Business One | Medium | Financial Management, Sales & Customer Management, Purchasing & Inventory Management, Analytics & Reporting | Quality management, Quality inspections, Supplier quality management | On-premise, Cloud | Small to medium-sized enterprises | 70,000+ |

| Epicor ERP | High | Financial Management, Supply Chain Management, Production Management, Sales Management, Project Management, HR | Quality planning, Quality control, Quality assurance, Supplier quality management | On-premise, Cloud | Small to large enterprises | 20,000+ |

What is the best ERP for manufacturing in 2021?

We review the best ERP software for manufacturing? We compare and rank the best ERP software for manufacturers in 2021 including SAP Business One, Netsuite, Infor & more.

ERP Requirements Gathering (RFI, RFP) Template Excel

Start your ERP evaluation process with our RFI & RFP Excel template for the engineering industry.

ERP Project Budget Calculator Template

Calculate the costs of your ERP project with our prebuilt budget calculator.

ERP QMS System Guide & FAQ

What is a QMS system?

A quality management system (QMS) is a set of policies, procedures, and processes used by an organization to ensure that its products or services meet or exceed customer expectations and are consistent with applicable regulations and standards. The primary goal of a QMS is to improve the quality of the organization's products or services, and to continually improve the efficiency and effectiveness of its operations.

A QMS typically includes the following components:

-

Quality policy: A statement by top management describing the organization's commitment to quality.

-

Quality objectives: Specific, measurable goals related to quality that the organization aims to achieve.

-

Quality manual: A document that describes the organization's quality management system and how it is implemented.

-

Procedures: Step-by-step instructions for carrying out specific tasks and processes related to quality management.

-

Work instructions: Detailed instructions for performing specific tasks and activities related to quality management.

-

Records: Documentation that provides evidence that quality management activities have been carried out as intended.

-

Audits: A systematic, independent examination of the organization's quality management system to ensure that it is effective and complies with applicable standards.

A QMS can help an organization improve its quality, increase customer satisfaction, reduce costs, and enhance its reputation. It is often used in industries such as healthcare, manufacturing, and food service, where quality and safety are critical concerns.

What is an ERP system?

An Enterprise Resource Planning (ERP) system is a type of software that organizations use to manage and integrate their business processes and data across various functions and departments, such as finance, human resources, supply chain management, production, and customer relationship management.

ERP systems provide a single, unified platform for managing all aspects of a company's operations, from inventory and procurement to financial reporting and customer support. This helps to streamline workflows, reduce data entry errors, and improve decision-making by providing real-time insights into business performance.

ERP systems typically include the following features:

-

Centralized database: A single database that stores all relevant information about the organization's operations, including financial data, customer information, and inventory levels.

-

Integrated modules: Modules for managing various business functions, such as accounting, human resources, procurement, inventory management, and production.

-

Workflow automation: Tools for automating business processes, such as purchase orders, invoices, and payroll.

-

Analytics and reporting: Reporting tools that allow users to generate reports and analyze data to identify trends, patterns, and opportunities.

What is ERP vs QMS?

ERP and Quality Management Systems (QMS) are two different types of systems that serve different purposes within an organization.

ERP systems are primarily designed to manage and integrate business processes across various functions and departments within an organization, including finance, human resources, supply chain management, production, and customer relationship management. The main goal of an ERP system is to streamline workflows, increase efficiency, reduce costs, and improve decision-making by providing real-time insights into business performance.

On the other hand, a Quality Management System (QMS) is a set of policies, procedures, and processes that an organization uses to ensure that its products or services meet or exceed customer expectations and comply with applicable regulations and standards. The main goal of a QMS is to improve the quality of the organization's products or services, and to continually improve the efficiency and effectiveness of its operations.

While there may be some overlap between the two systems, they serve different purposes and address different areas of an organization's operations. An ERP system can help an organization manage its operations more efficiently, but it does not necessarily ensure that the organization's products or services meet quality standards. A QMS, on the other hand, is specifically designed to ensure quality standards are met and maintained throughout the organization's operations.

ERP & Quality Management Software Features & Modules

The features and modules of a QMS ERP software can vary depending on the specific software being used, as well as the needs and requirements of the organization using it. However, some common features and modules of QMS ERP software include:

-

Document control: This module provides a centralized location for managing and controlling all documents related to the QMS, such as policies, procedures, work instructions, and forms. It also includes version control, access control, and review/approval workflows.

-

Audit management: This module enables organizations to manage internal and external audits, including planning, scheduling, conducting, and reporting. It also tracks corrective and preventive actions resulting from audits.

-

Non-conformance management: This module allows organizations to manage non-conformances or deviations from established procedures, including identification, investigation, corrective and preventive actions, and closure.

-

Change control: This module manages changes to documents, processes, or systems within the QMS. It includes change requests, impact assessments, approval workflows, and tracking of implementation and verification.

-

Risk management: This module identifies and assesses risks within the organization's processes, products, or services. It includes risk analysis, risk assessment, risk evaluation, and risk treatment.

-

Training management: This module tracks employee training and competency related to the QMS. It includes training plans, scheduling, delivery, and tracking of completion and effectiveness.

-

Supplier management: This module manages relationships with suppliers, including qualification, evaluation, selection, monitoring, and development. It also tracks supplier performance and non-conformances.

-

Quality metrics and reporting: This module provides tools for measuring and analyzing quality performance, such as key performance indicators (KPIs), trend analysis, and benchmarking. It also generates reports for management review and decision-making.

These features and modules are typically integrated within a single software platform, providing a centralized and streamlined approach to managing the QMS and supporting the organization's overall quality management goals.

What is the cost of ERP QMS Systems?

The cost of ERP quality management software can vary widely depending on a number of factors, such as the size of the organization, the complexity of the software, the level of customization required, and the number of users.

Some ERP quality management software solutions may be available as open source software, which can be downloaded and used for free, but may require customization and implementation support that can add to the cost.

For commercial software solutions, the cost can range from a few thousand dollars to several hundred thousand dollars or more, depending on the features and modules required, the number of users, and the level of support and maintenance included.

In addition to the upfront costs of purchasing the software, there may be ongoing costs for maintenance, updates, and support, as well as implementation costs for training and data migration.

Start Your ERP Journey With ERP Research

We help manufacturing firms to prepare for ERP change by guiding them through each stage of the process:

-

Build An ERP Business Case 2-3 weeksA solid business case is a foundation you need if you are going to persuade your organization to consider enterprise resource planning (ERP) implementation. Download Business Case Template

-

Compare ERP Vendors 2-3 weeksIt’s critical to understand which ERP vendor is right for your business. Before you decide on the vendor for your company, take a look at our solution pages to find out which vendor would be best. Compare ERP Vendors

-

Get Pricing Estimates 1-2 weeksOur exclusive process removes all the salesmen from the equation and gets you real pricing estimates from every qualified vendor. Contact Us For Pricing

-

Organize A Solution Demo 1-2 weeksDuring a demo, you will learn about how large corporations are making use of ERP software and how they are improving their business practices. Book A Demo

-

Build ERP Requirements 3-4 weeksIf you're looking to buy an Enterprise Resource Planning (ERP) system or upgrade your internal systems you will need a clear definition of all the functions, features and capabilities that you expect. You can approach this challenge by building what's called an ERP requirements document. Download ERP Requirements Template

-

Shortlist 4-8 Vendors 1 weekOne of the most important phases in the ERP project lifecycle is selecting the right software vendor. Ideally, you should shortlist 4-8 vendors - based on their credentials and your requirements. Contact Us To Shortlist Vendors

.png?width=278&name=sap-s-4hana-logo%20(2).png)