Best ERP Software for Pharmaceuticals & Biotechnology

ERP for pharmaceuticals enable companies to stay compliant, assure quality and drive efficiencies to improve patient outcomes and bottom lines.

At ERP Research we provide independent advice and analysis for pharma ERP systems.

Top 10 ERP Systems For Pharmaceuticals

Learn everything you need to know about the best ERP solutions for pharmaceuticals in our detailed solution comparison report. We compare pharmaceutical industry ERP including SAP, Netsuite, Oracle, Microsoft, Infor and more.

Best Pharma & Biotech ERP for SMB & SME

ERP software for pharmaceutical companies that are small and midsized need to strike a fine balance between depth of functionality and cost. Below are some ERP solutions for pharmaceutical & biotech companies in the SMB space:

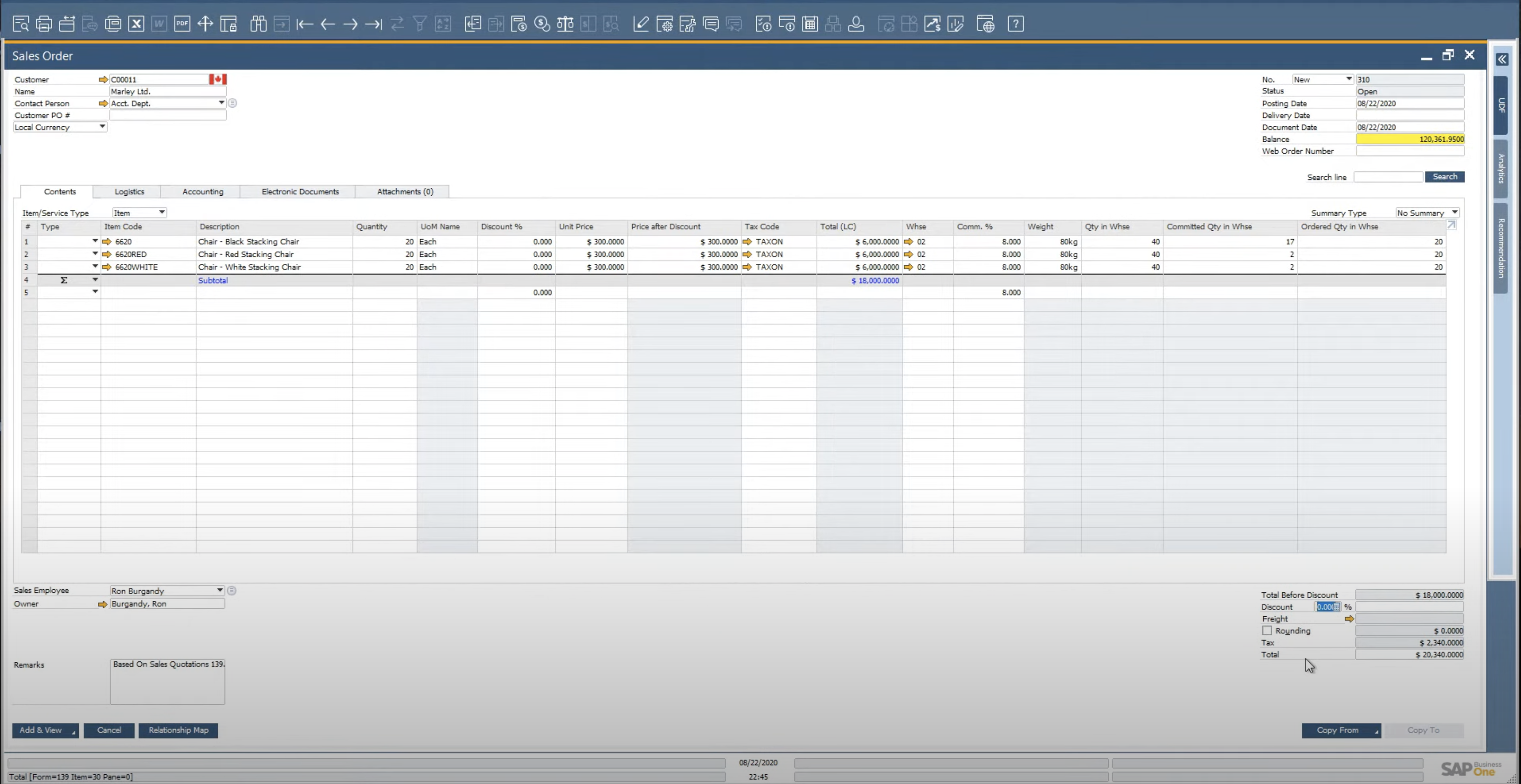

Infor CloudSuite Industrial (Syteline)

Infor CSI is well suited to small and medium sized pharmaceutical companies looking for a flexible ERP solution. Infor ERP provides tight integration between key business functions with a depth of functionality for pharmaceuticals.

QAD Systems

QAD Systems is used by many small and growing pharmaceutical companies and pharma manufacturers. This pharma ERP can scale to several thousand employees.

Microsoft Dynamics Business Central

Microsoft Dynamics Business Central is used as a pharma ERP by several small pharma companies and has developed its own ecosystem of specialized partners.

Best Pharma & Biotech ERP for Growing & Mature Enterprises

ERP for pharmaceutical companies that are already well established brings more functionality and greater flexibility.

Below are popular ERP systems for pharmaceutical companies that operate at scale, globally:

Microsoft Dynamics 365

Many pharmaceutical companies are beginning to explore Microsoft Dynamics as their pharmaceutical ERP. The solution provides a great degree of flexibility plus a large partner ecosystem that has developed many pharmaceutical industry add-ons.

Oracle ERP Cloud

Oracle ERP Cloud is a growing solution for pharmaceutical companies searching for an ERP solution. With one end to end platform, Oracle ERP Cloud sets the foundation for strong finance and operations capabilities plus HCM and much more.

Cloud ERP for Pharma

Cloud ERP for pharmaceutical companies enables pharma companies to streamline their business processes without having the hassle of mainting On-Premise ERP infrastructure and support teams:

Microsoft Dynamics 365

Many pharmaceutical companies are beginning to explore Microsoft Dynamics as their pharmaceutical ERP. The solution provides a great degree of flexibility plus a large partner ecosystem that has developed many pharmaceutical industry add-ons.

SAP Business ByDesign

SAP Business ByDesign is a Cloud ERP solution which has earned many growing customers in the pharmaceutical industry with its integrated suite of functionality spanning sales, production, inventory, quality and serialisation & batch traceability.

Pharma ERP Software Comparison

| ERP System | Hosting Options | Core Modules | Approx. Cost | Approx. Number of Customers | Known Customers in the Pharma Industry |

|---|---|---|---|---|---|

| SAP Business One | On-premise, Cloud, Hybrid | Financials, Sales, Purchasing, Inventory, Production, Service, Project Management, CRM | Starts at $20,000 for professional licenses | 60,000+ | BioVectra, Chemische Fabrik Kreussler |

| SAP S/4 HANA | On-premise, Cloud, Hybrid | Finance, Procurement, Sales, Manufacturing, Service, Project Management, Product Lifecycle Management, Supply Chain, Asset Management, R&D and Engineering | Usually $10,000+ per user for licenses | 10,000+ | Pfizer, Novartis |

| Infor CloudSuite Industrial | On-premise, Cloud, Hybrid | CRM, Product Configuration, Quality Management, Shop Floor Control, Project Management, Supply Chain Management | Varies, can go into hundreds of thousands depending on scale | 5,000+ | Elkay Manufacturing, Bio-techne |

| QAD Systems | Cloud, On-premise | Financials, Customer Management, Manufacturing, Supply Chain, Service and Support, Analytics | Starts at $150 per user per month | 2,000+ | Sandoz, Daiichi Sankyo |

| NetSuite | Cloud | Financials/ERP, CRM, eCommerce, Professional Services Automation, Human Capital Management | Starts at $999 per month plus $99 per user per month | 20,000+ | Hampton Creek, Healing Natural Oils |

| Microsoft Dynamics | On-premise, Cloud, Hybrid | Financial Management, Supply Chain Management, Sales & Service Management, Project Management, Manufacturing, Human Resources | Starts at $20-200 per user per month | 120,000+ | Omnicell, Pierre Fabre Medicament |

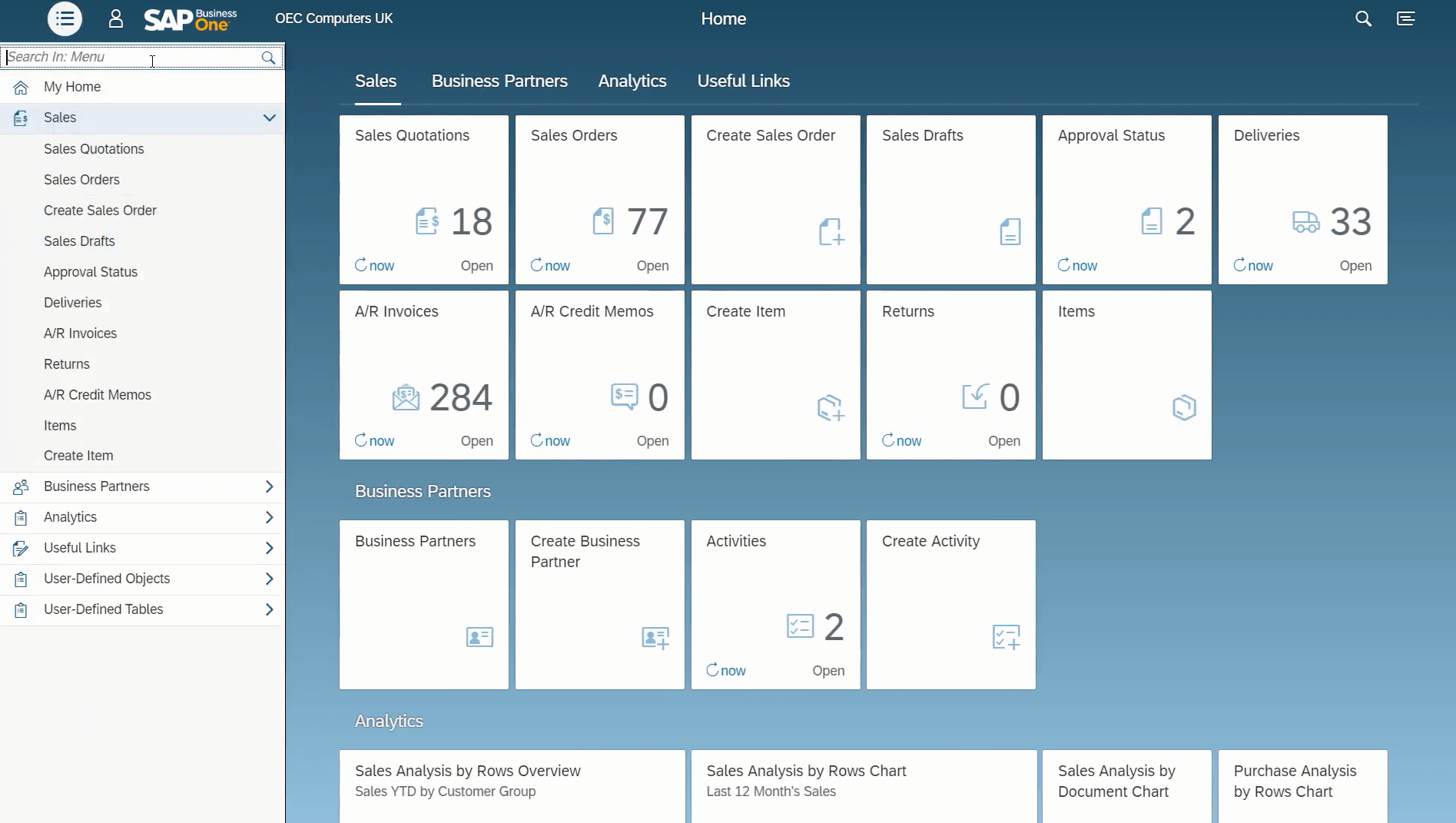

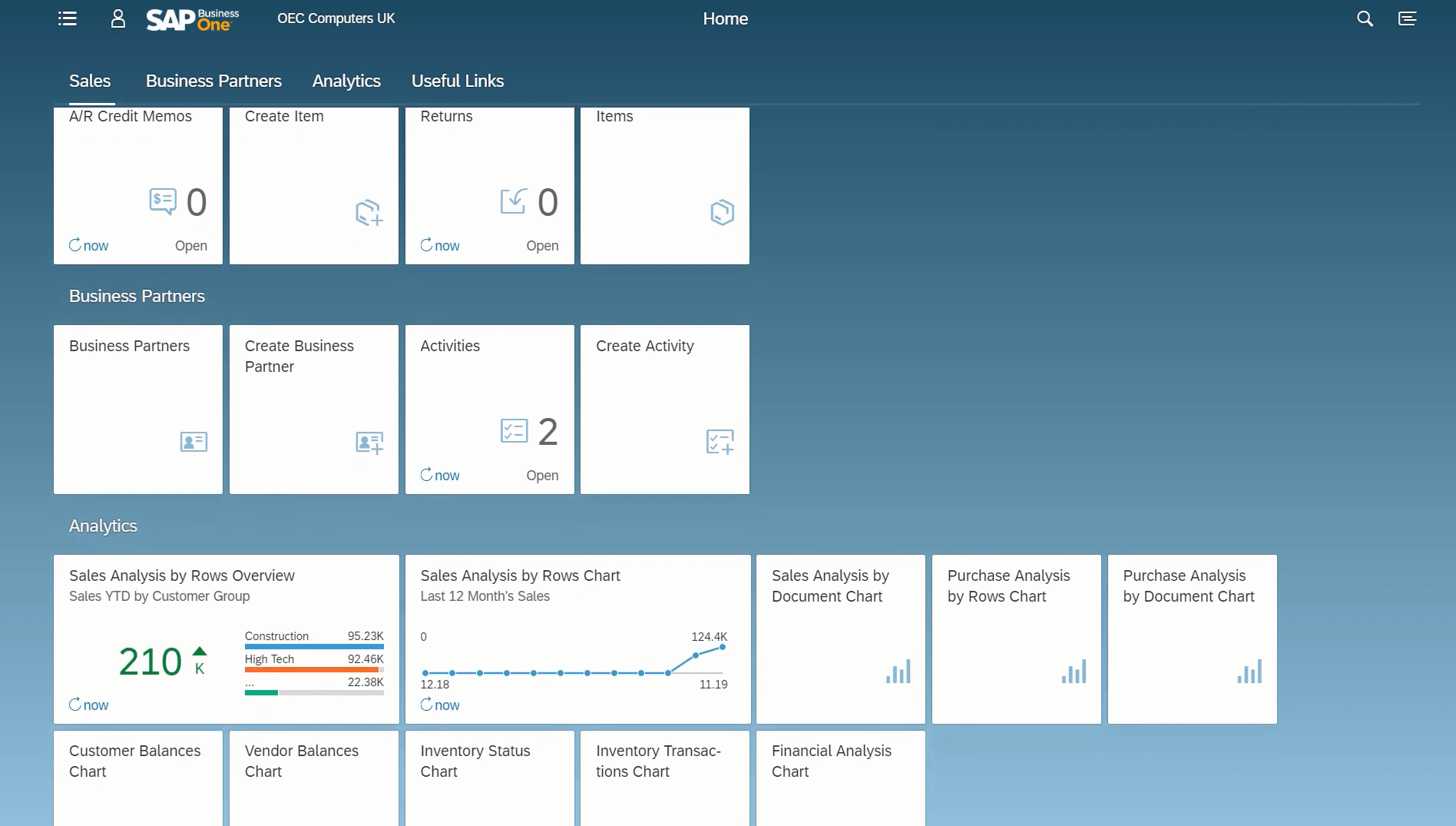

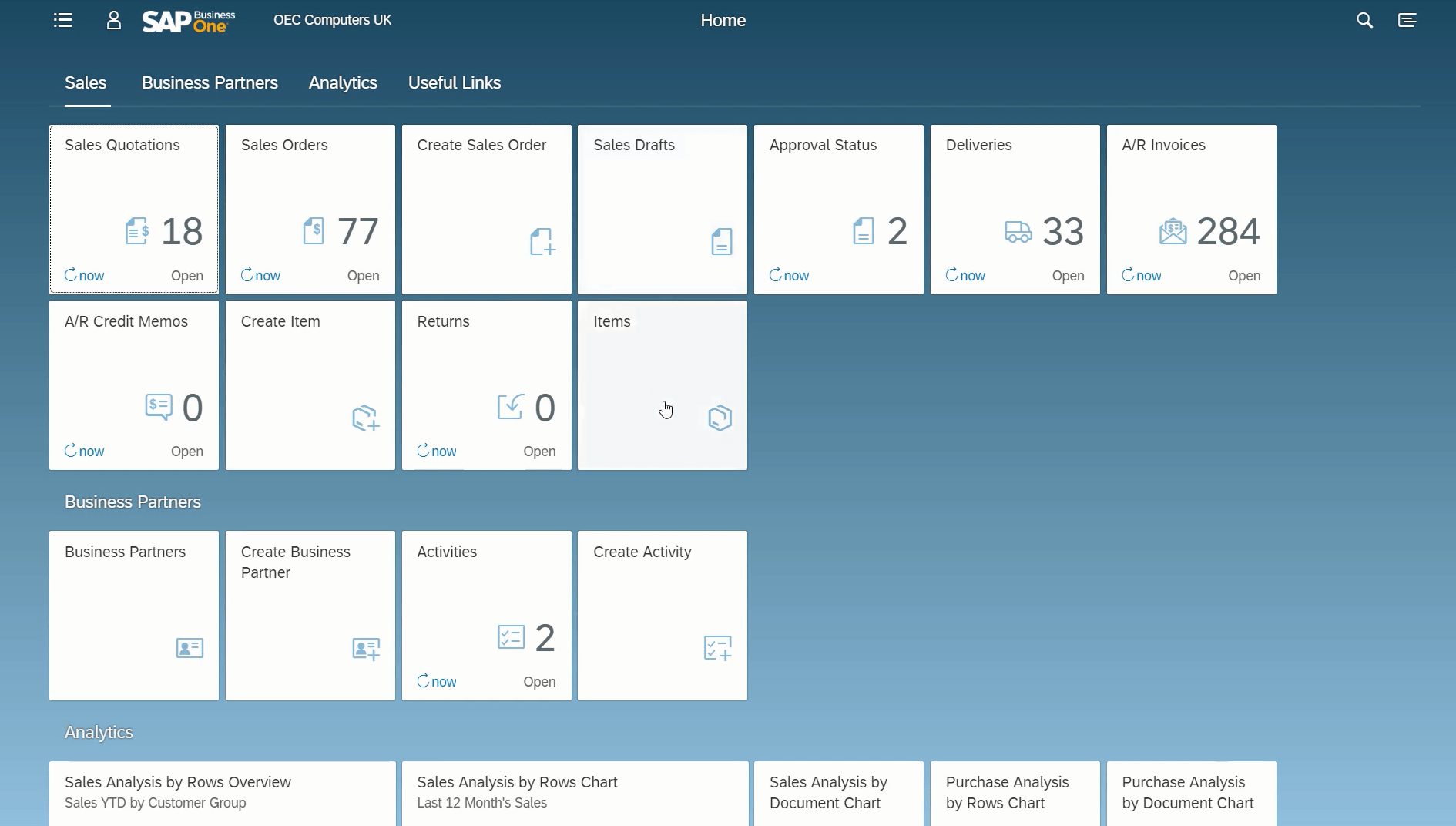

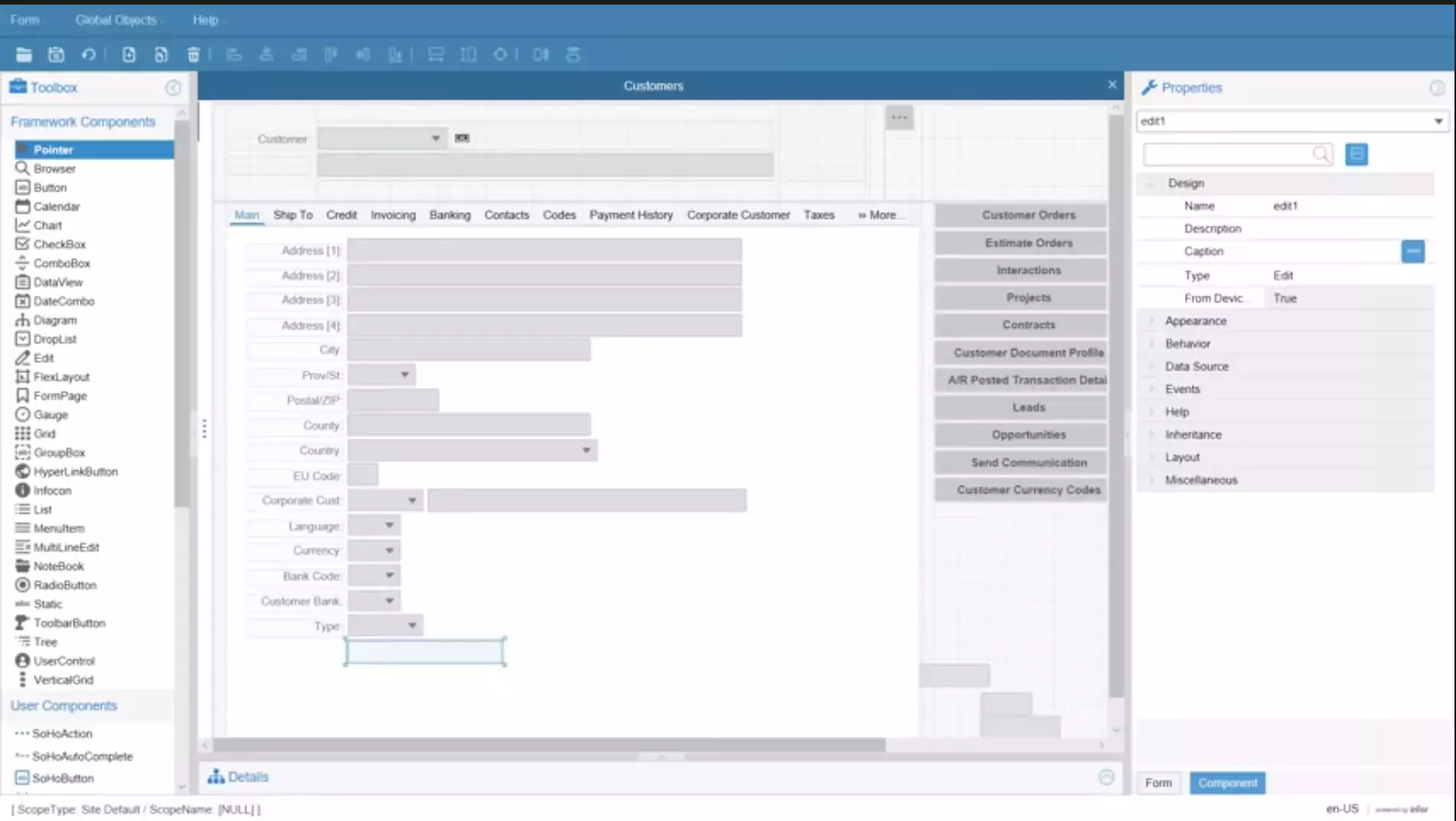

SAP Business One

SAP Business One is an Enterprise Resource Planning (ERP) software that is designed to manage various business functions such as financials, sales, inventory, and operations. Pharmaceutical companies can use SAP Business One to manage their entire business process, from procurement and inventory management to production and distribution. Here are some ways SAP Business One can be used as an ERP for pharmaceutical companies:

-

Batch and Lot Management: SAP Business One provides batch and lot traceability features that enable pharmaceutical companies to track and manage the quality of their products. This feature allows the company to identify any issues with a particular batch and trace it back to the raw materials used to produce it.

-

Quality Control: Pharmaceutical companies are required to comply with strict regulations regarding the quality of their products. SAP Business One provides quality control features that enable the company to manage quality control processes such as testing, approval, and release of products.

-

Regulatory Compliance: The pharmaceutical industry is heavily regulated, and companies must comply with various regulatory requirements. SAP Business One can help companies comply with regulations such as Good Manufacturing Practices (GMP), Good Laboratory Practices (GLP), and Good Clinical Practices (GCP).

-

Supply Chain Management: SAP Business One provides supply chain management features that enable pharmaceutical companies to manage their entire supply chain, from procurement to distribution. This includes managing vendors, tracking inventory levels, and managing orders and shipments.

-

Financial Management: SAP Business One provides financial management features that enable pharmaceutical companies to manage their financial transactions, including accounts payable, accounts receivable, and general ledger.

-

Reporting and Analytics: SAP Business One provides reporting and analytics features that enable pharmaceutical companies to monitor and analyze their business performance. This includes tracking sales, inventory levels, and production costs, among other metrics.

Infor CloudSuite Industrial

Infor CloudSuite Industrial (CSI) is a comprehensive Enterprise Resource Planning (ERP) solution that can be used in various industries, including the pharmaceutical industry. Here are some ways in which CSI can be used as an ERP for pharma:

-

Inventory management: One of the critical requirements of the pharma industry is managing inventory. CSI can help streamline inventory management by providing real-time data on stock levels, expiration dates, and batch tracking. This helps pharma companies ensure they have the right amount of raw materials and finished products available to meet demand while avoiding stockouts and expired products.

-

Quality control: The pharma industry has strict regulations governing the quality of products. CSI can help track and manage quality control processes, including product testing, compliance, and certification. This can help ensure that products meet regulatory requirements and are of high quality.

-

Production planning: CSI can help pharma companies plan and manage their production processes efficiently. The solution can help optimize production schedules based on demand forecasts, resource availability, and lead times. This helps pharma companies meet customer demand while minimizing production costs.

-

Supply chain management: The pharma industry involves a complex supply chain that spans from raw material suppliers to end customers. CSI can help manage the supply chain by providing real-time data on supplier performance, logistics, and distribution. This helps pharma companies ensure they have the right materials and products available at the right time and location.

-

Financial management: CSI can help pharma companies manage their financial processes, including budgeting, accounting, and reporting. This can help pharma companies maintain accurate financial records and comply with regulatory requirements.

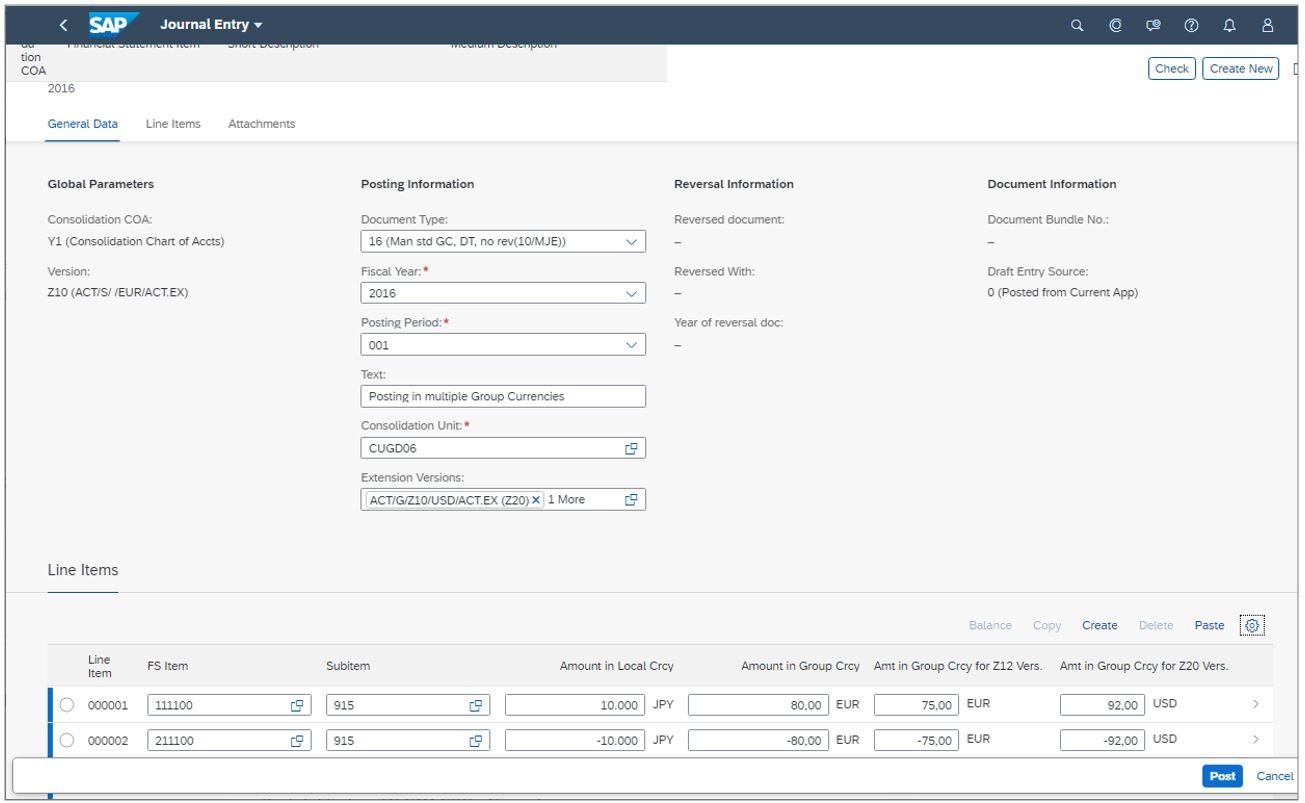

SAP S/4 HANA

SAP S/4HANA is an Enterprise Resource Planning (ERP) system that can be used by the pharmaceutical industry to improve operational efficiency, reduce costs, and enhance decision-making capabilities. Here are some ways in which SAP S/4HANA can be used as an ERP for the pharmaceutical industry:

-

Compliance: The pharmaceutical industry is highly regulated, and companies must comply with various regulations such as the FDA, EMA, and other regulatory bodies. SAP S/4HANA helps pharmaceutical companies comply with these regulations by providing real-time monitoring and control of quality and compliance processes.

-

Supply chain management: The pharmaceutical industry involves complex supply chains that include multiple partners, from raw material suppliers to distributors. SAP S/4HANA can help manage the entire supply chain, from procurement and production to inventory management and distribution.

-

Financial management: SAP S/4HANA offers a comprehensive financial management system that can help pharmaceutical companies manage their finances more efficiently. It includes features such as accounts payable and receivable, general ledger, asset management, and financial reporting.

-

Quality management: The pharmaceutical industry requires a high degree of quality control to ensure the safety and efficacy of their products. SAP S/4HANA offers quality management features that help ensure compliance with regulatory requirements and improve product quality.

-

Production planning and scheduling: SAP S/4HANA provides tools to help pharmaceutical companies plan and schedule production more effectively. It includes features such as demand planning, production planning, and scheduling, and capacity planning.

-

Sales and marketing: SAP S/4HANA offers features that help pharmaceutical companies manage their sales and marketing activities. It includes tools for customer management, lead tracking, campaign management, and sales forecasting.

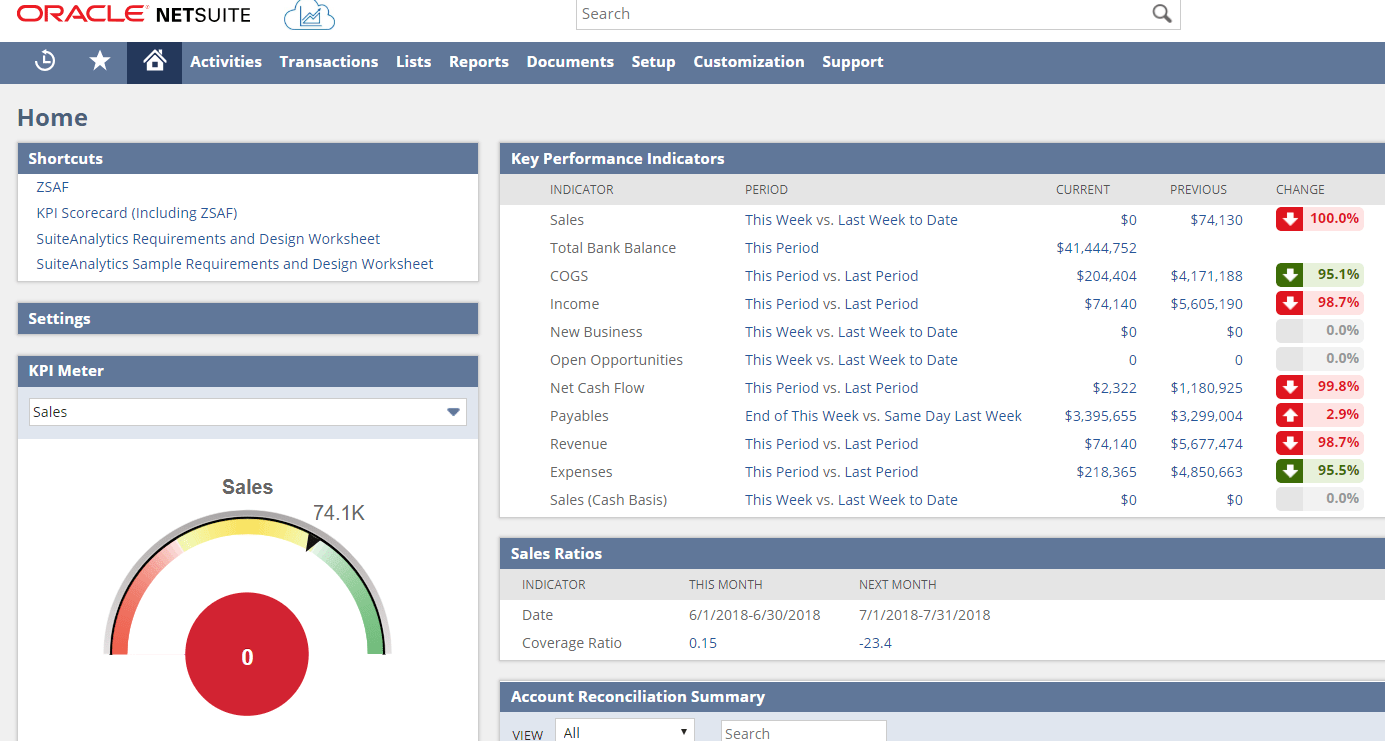

NetSuite

NetSuite can be used as an ERP (Enterprise Resource Planning) system for the pharmaceutical industry by providing various features and functionalities that can support the unique needs of the industry. Here are some ways NetSuite can be used in the pharmaceutical industry:

-

Inventory Management: The pharmaceutical industry requires careful tracking and management of inventory due to the highly regulated nature of the industry. NetSuite can provide real-time visibility into inventory levels, expiry dates, and lot numbers, allowing pharmaceutical companies to ensure compliance with regulations and prevent wastage of inventory.

-

Compliance Management: The pharmaceutical industry is highly regulated, with strict requirements for documentation, reporting, and quality control. NetSuite can help pharmaceutical companies manage compliance by providing tools for tracking and documenting all aspects of production and distribution, ensuring that all processes meet regulatory requirements.

-

Financial Management: NetSuite can provide comprehensive financial management capabilities, including accounts payable, accounts receivable, general ledger, and financial reporting. Pharmaceutical companies can use NetSuite to track and manage finances across multiple locations, currencies, and entities, and provide visibility into financial performance.

-

Sales and Distribution: NetSuite can provide tools for managing sales and distribution processes, including order management, pricing, and fulfillment. Pharmaceutical companies can use NetSuite to manage orders, track inventory levels, and ensure timely and accurate delivery of products to customers.

-

Manufacturing Management: NetSuite can help pharmaceutical companies manage the manufacturing process, from raw materials to finished products. NetSuite provides tools for managing production schedules, tracking production costs, and ensuring quality control at every stage of the manufacturing process.

-

CRM: NetSuite's Customer Relationship Management (CRM) system can help pharmaceutical companies manage relationships with customers, suppliers, and other stakeholders. NetSuite can provide tools for managing sales leads, tracking customer interactions, and ensuring customer satisfaction.

Pharmaceutical ERP Frequently Asked Questions

What is the best ERP for the pharmaceutical industry?

The best ERP for pharma is generally considered to be SAP. However the answer really depends on the requirements of your pharmaceutical, biotech or life sciences business. If your organization is a multinational pharmaceutical manufacturer with hundreds or thousands of employees, then sure SAP is probably the right answer. However, if your pharmaceutical or biotechnology business is smaller then there could be several answers. We see small life sciences companies using more nimble pharma ERP software solutions such as Oracle Netsuite, Oracle ERP Cloud, Odoo, Infor Cloudsuite Industrial and more.

What are the key features and modules of pharma ERP software?

ERP software for pharmaceuticals, biotechnology and life sciences business includes all of the typical modules within almost all ERP systems including:

- Financial Management & Accounting

- Sales & Distribution

- Supply Chain

- Procurement

- Manufacturing & Production

- Human Resources

- Reporting & Analytics

Plant Maintenance - Asset Management

However, the best pharma ERP solutions for pharmaceuticals also tend to include industry specific modules and functionalities which include:

- FDA, MHRA compliance.

- Recipe Management

- Life sciences ISO certifications.

- Traceability

- Batch Management

- Serialization

- Recipe Management

- SOX Compliance

- Audit Trails

How much does ERP for pharmaceuticals cost?

Costs for pharma ERP in the pharmaceutical industry can range from $100,000 in Year 1 to several millions. Pharma ERP costs are typically made up of software licensing, support and implementation.

Increasingly, pharmaceutical and biotechnology companies are turning to Cloud ERP software solutions which are paid for on a subscription basis. Annual fees for Cloud ERP software for pharma can range anywhere from $500-2000 per user.

Support costs are typically a percentage of your software license cost and can fluctuate depending on the level of support your organization requires and how many hours of support you consume.

Life sciences and pharmaceutical ERP implementations are often the biggest up front cost and will depend on the pharma ERP software you choose, your organizations size, the ERP project scope and your resourcing model.

Can Pharmaceuticals companies use Cloud ERP?

Cloud ERP for Pharmaceuticals does exist and is used by many pharma companies. Additional effort and care must go into upgrading and revalidating your business processes but the benefits often outweigh the issues this can cause.

How long does it take to implement pharma ERP?

Implementing a Pharma ERP system is a multifaceted project, heavily influenced by several factors. The time it takes to successfully roll out a Pharma ERP varies widely depending on the size and complexity of your pharmaceutical organization, the intricate nature of your business processes, and the level of customization the Pharma ERP requires.

For small to mid-sized pharmaceutical companies, the typical time frame for Pharma ERP implementation ranges between 6 to 12 months. Larger corporations with more intricate systems and processes may find that their Pharma ERP implementation extends over a period of 1 to 2 years or more.

The duration of Pharma ERP implementation can also hinge on factors such as data migration from existing systems to the new Pharma ERP, employee training on the Pharma ERP system, and how smoothly the Pharma ERP integrates with other systems already in place.

Bear in mind, these are merely ballpark figures. Realistically, the actual implementation time for a Pharma ERP system can fluctuate, depending on organizational readiness for change, resource allocation, and the effectiveness of project management.

Given the magnitude and complexity of Pharma ERP implementation, a staggered approach is often beneficial. By implementing the Pharma ERP system in phases, timeline and risk management become more efficient.

Additionally, remember that post-implementation, a Pharma ERP system requires an adjustment period. This fine-tuning phase ensures that your Pharma ERP system is optimally functioning, catering to your needs, and delivering the expected benefits. This adjustment period can span several months following the primary Pharma ERP implementation.

Can Pharma ERP integrate with CMOs?

Yes, a Pharma ERP system can indeed be integrated with Contract Manufacturing Organizations (CMOs). In the pharmaceutical industry, partnerships with CMOs are very common, and these organizations play an essential role in the production and distribution process.

A properly designed and implemented Pharma ERP system should have the capability to interface with systems used by CMOs. This integration allows for seamless communication and data exchange, providing end-to-end visibility and control over the entire supply chain.

Specific functionalities that can be achieved through this integration include:

- Real-time tracking and reporting of production and inventory status.

- Streamlined procurement and production planning processes.

- Improved batch tracking and traceability, ensuring compliance with regulations.

- Enhanced forecasting and demand planning.

- Automated data exchange, reducing manual tasks and the risk of errors.

To ensure successful integration, it's important to choose a Pharma ERP system that has robust integration capabilities. Moreover, both parties involved – the pharmaceutical company and the CMO – need to work together closely during the integration process. Clear communication, defined expectations, and an understanding of the respective workflows and processes are essential. This will ensure that the integration meets the needs of both parties, and that the full benefits of the Pharma ERP system are realized.

How can Pharma ERP support regulation?

Pharmaceutical companies operate under numerous and stringent regulations that are designed to ensure the safety, efficacy, and quality of the drugs they produce. A Pharma ERP system can play a crucial role in helping companies adhere to these regulations by providing integrated and automated systems to track and document various aspects of the production process. Here are some of the key regulations:

-

Good Manufacturing Practice (GMP): This is a system for ensuring that products are consistently produced and controlled according to quality standards. It covers all aspects of production from the raw materials, premises, and equipment to the training and hygiene of staff.

-

FDA 21 CFR Part 11: This regulation from the U.S. Food and Drug Administration (FDA) sets forth the requirements for electronic records and electronic signatures.

-

EU Annex 11: Similar to FDA 21 CFR Part 11, EU Annex 11 pertains to computerized systems used in the manufacture of pharmaceutical products.

-

Data Integrity and ALCOA+: Data integrity refers to the accuracy, consistency, and reliability of data. ALCOA+ is a framework for data integrity that stands for Attributable, Legible, Contemporaneous, Original, and Accurate, with the "+" referring to additional requirements including completeness, consistency, enduring and available.

A Pharma ERP can support compliance with these regulations in several ways:

-

Automation and Integration: ERP systems can automate and integrate various processes, reducing the risk of human error and improving overall efficiency. This aids in maintaining GMPs, which require consistency and standardization in production.

-

Audit Trails and Electronic Signatures: To comply with FDA 21 CFR Part 11 and EU Annex 11, Pharma ERP systems can offer features such as automatic audit trails and electronic signature capabilities. This ensures that all changes to critical data are logged and traceable.

-

Data Integrity and Validation: ERP systems can help maintain data integrity by ensuring that data is accurate, complete, and reliable. It also provides validation tools to check the accuracy and integrity of data.

-

Quality Control and Traceability: ERP systems can track and manage all aspects of production, from raw material sourcing to final product distribution. This provides complete traceability, crucial for recalls and for demonstrating compliance with regulations.

-

Documentation and Reporting: ERP systems can automatically generate and store necessary documentation and reports. This can be useful during inspections and audits.

Remember, while a Pharma ERP can greatly aid in regulatory compliance, it's not a standalone solution. It needs to be part of a broader compliance strategy that includes employee training, regular audits, and a company-wide commitment to quality and integrity.

Can pharma ERP support GMP?

Good Manufacturing Practices (GMP) are a collection of regulations that pharmaceutical and other companies involved in the production of medicines, food, and medical devices must adhere to. GMP ensures these products are safe, pure, and effective. A Pharma ERP system can support adherence to GMP in several ways:

-

Quality Control: A Pharma ERP system can help manage and automate quality control processes to ensure consistency in operations. It allows for real-time monitoring and alerts, helping to identify and resolve issues quickly and efficiently.

-

Traceability: ERP systems offer complete traceability, from sourcing raw materials to manufacturing, packaging, and distribution. This aids in quality assurance, recall management, and in demonstrating GMP compliance during audits.

-

Batch Management: ERP software provides efficient batch management capabilities, tracking the complete life cycle of a batch. This includes information such as ingredients, process parameters, equipment used, personnel involved, and dates and times of each step.

-

Document Management: Compliance with GMP requires thorough documentation. An ERP system can help manage and store all the necessary documents, making it easy to retrieve them during audits or inspections.

-

Process Standardization: ERP systems help standardize processes across various departments, reducing human error and promoting consistency in operations, which is crucial for maintaining GMP.

-

Inventory Management: ERP systems can manage and track inventory in real-time, ensuring the appropriate materials are always available and that they're stored under correct conditions, supporting GMP guidelines.

-

Validation: GMP requires validation of processes to ensure consistency and quality. ERP systems can collect and analyze data to support validation efforts.

-

Training Records: GMP requires that employees are adequately trained. An ERP system can track employee training records and remind when re-training is needed.

While a Pharma ERP system plays a crucial role in supporting GMP, it is important to remember that it's part of a broader ecosystem. The organization's culture, commitment to quality, and overall understanding of GMP regulations are equally vital in maintaining GMP compliance.

Do Pharma ERP systems support FDA 21?

Yes, Pharma ERP systems are designed to support compliance with FDA 21 CFR Part 11 regulations. FDA 21 CFR Part 11 refers to the U.S. Food and Drug Administration's regulations for electronic records and electronic signatures, providing criteria to ensure that electronic records and signatures are trustworthy, reliable, and equivalent to paper records.

Here are some ways a Pharma ERP can support FDA 21 CFR Part 11 compliance:

-

Audit Trails: The ERP system should provide comprehensive audit trails of all actions related to electronic records. These trails should document what changes were made, who made them, and when they were made.

-

Electronic Signatures: ERP systems should support electronic signatures. These signatures need to be linked to their respective electronic records and should include the printed name of the signer, the date and time of signing, and the meaning associated with the signature (such as review, approval, responsibility, or authorship).

-

User Access Controls: To ensure that only authorized individuals can use the system, the ERP should provide strong user access controls. This includes unique user IDs and robust password policies.

-

Data Integrity and Security: The ERP system must ensure that electronic records are accurate, complete, and secure from unauthorized access or manipulation.

-

Validation: ERP systems must be validated to ensure accuracy, reliability, and the ability to discern invalid or altered records.

-

Backup and Recovery: The ERP should have mechanisms in place for backing up and recovering data, ensuring that electronic records are retrievable and readable throughout the required retention period.

In summary, while a Pharma ERP system can greatly aid in supporting compliance with FDA 21 CFR Part 11, it is also crucial for the organization to have a clear understanding of these regulations and develop robust internal controls, procedures, and policies to ensure complete compliance.

How do ERP systems support GxP?

GxP is a general term for good practice quality guidelines and regulations in the life sciences industry. The "G" stands for "good," while the "x" can stand for various fields, including "manufacturing" (GMP), "laboratory" (GLP), "clinical" (GCP), "distribution" (GDP), and more. These guidelines ensure that products are safe, meet their intended use, and adhere to quality processes during production and control.

Pharma ERP systems play an essential role in supporting GxP compliance by offering features that enable traceability, process control, validation, and documentation. Here's how:

-

Traceability: Pharma ERP systems maintain detailed records of the entire product lifecycle, from raw materials through production to distribution. This end-to-end traceability supports many aspects of GxP, including GMP and GDP.

-

Process Control: GxP guidelines emphasize control over the manufacturing and quality processes. ERP systems help standardize and automate these processes, reducing the risk of human error and ensuring consistency in product quality (supporting GMP).

-

Validation: GxP regulations often require validation of systems and processes. ERP systems can provide data and tools to help with this validation, ensuring that systems are working as intended and are reliable.

-

Documentation: Detailed documentation is a cornerstone of GxP compliance. ERP systems automate much of the record-keeping required by GxP, ensuring that records are accurate, complete, and readily available when needed. This is crucial for areas such as GCP and GLP.

-

Quality Management: Many ERP systems come with built-in Quality Management Systems (QMS) or can integrate with external ones. These systems help manage quality processes, corrective and preventive actions (CAPA), and change controls, all of which are critical for GxP compliance.

-

Data Integrity and Security: Data integrity is a key part of GxP. Pharma ERP systems help ensure that data is accurate, complete, and secure from unauthorized access or manipulation.

-

Training Records: GxP requires that employees are adequately trained. An ERP system can track employee training records and schedule training when needed.

Key ERP Modules & Features for Pharmaceuticals

ERP systems allow companies in the pharmaceutical & biotechnology industry to share data amongst different departments, eliminating information silos whilst enabling them to handle compliance and regulatory measures easily.

But what is the key ERP functionality for pharmaceutical and biotechnology companies? Which ERP modules are critical for pharmaceutical companies?

Accounting and Financials

Pharmaceutical ERP enables you to unite financials across multiple entities and geographies with tight integration to key pharmaceutical business processes.

Purchasing

Enable compliance and cost control with pharmaceutical ERP that provides approval matrixes, purchase requisitions, orders and control.

Production

Integrate with contract manufacturing organizations (CMO) or run production in house with pharmaceutical ERP that enables easy compliance and traceability.

Inventory Management

Monitor stock and inventory across multiple locations and perform real time valuations in pharmaceutical ERP software.

Quality Management

Modern pharmaceutical ERP gives you the power to control quality at all steps of your internal processes to ensure you can

Asset Management

Manage fixed assets within your pharmaceutical ERP solution and convert your R&D spend to assets on your balance sheet with pharmaceutical ERP.

Reporting and dashboards

Get one view of your pharmaceutical operation with inbuilt reporting and dashboards for your ERP solution.

Expenses Management

Automate expenses requisitions and approvals for your sales team or R&D team within your ERP system.

Sales management

Track & plan sales pipeline, score leads, prospects and forecast opportunities in real-time across territories, accounts and teams.

Customisation

Flexible ERP software that's built on an open and extensible foundation, allowing you to choose the features that suit your business needs.

Mobility

Access your ERP data at any time so you're more available to customers and take advantage of unexpected opportunities as they surface.

Updates and maintenance

Backed by the consistency of market-leading vendors, ERP software regularly updates to ensure an optimal user experience.

What is the best ERP for pharmaceuticals? Best Pharma ERP Systems 2021

Review the best ERP systems for small, midsize and large pharmaceuticals and biotechnology companies including Infor, NetSuite, SAP Business One, Microsoft Dynamics 365 and more.

ERP Requirements Gathering (RFI, RFP) Template Excel

Start your pharmaceutical ERP evaluation process with our RFI & RFP Excel template for the pharma & biotech industry.

ERP Project Budget Calculator Template

Calculate the costs of your pharmaceutical ERP project with our prebuilt budget calculator.

Start your ERP journey with ERP Research

-

Build An ERP Business Case 2-3 weeksA solid business case is a foundation you need if you are going to persuade your organization to consider enterprise resource planning (ERP) implementation. Download Business Case Template

-

Compare ERP Vendors 2-3 weeksIt’s critical to understand which ERP vendor is right for your business. Before you decide on the vendor for your company, take a look at our solution pages to find out which vendor would be best. Compare ERP Vendors

-

Get Pricing Estimates 1-2 weeksOur exclusive process removes all the salesmen from the equation and gets you real pricing estimates from every qualified vendor. Contact Us For Pricing

-

Organize A Solution Demo 1-2 weeksDuring a demo, you will learn about how large corporations are making use of ERP software and how they are improving their business practices. Book A Demo

-

Build ERP Requirements 3-4 weeksIf you're looking to buy an Enterprise Resource Planning (ERP) system or upgrade your internal systems you will need a clear definition of all the functions, features and capabilities that you expect. You can approach this challenge by building what's called an ERP requirements document. Download ERP Requirements Template

-

Shortlist 4-8 Vendors 1 weekOne of the most important phases in the ERP project lifecycle is selecting the right software vendor. Ideally, you should shortlist 4-8 vendors - based on their credentials and your requirements. Contact Us To Shortlist Vendors

Find & Compare ERP Software for the Pharmaceuticals Industry

Use our free tool to find and compare the market leading ERP software and solutions for pharmaceuticals. See how ERP system solutions including NetSuite, Epicor, Infor & SAP Business One stack up against the competition.

.png?width=278&name=sap-s-4hana-logo%20(2).png)