Material Requirements Planning (MRP) Software

MRP software helps manufacturing companies to increase productivity and efficiency. Material requirements planning systems and software streamlines the process of securing the raw materials required to manufacture products.

At ERP Research, we help manufacturers of all sizes to find MRP and ERP software.

Top 10 ERP Systems For Manufacturing

Learn everything you need to know about the best ERP solutions for manufacturers in our detailed solution comparison report. We compare top manufacturing ERP software such as SAP, Microsoft, Oracle and more.

MRP Software for Small Businesses

Small and medium sized (SME) manufacturing firms need ERP systems which are cost effective, fast to implement and scalable.

Many manufacturing organizations have adopted ERP solutions such as these to handle their growth efficiently:

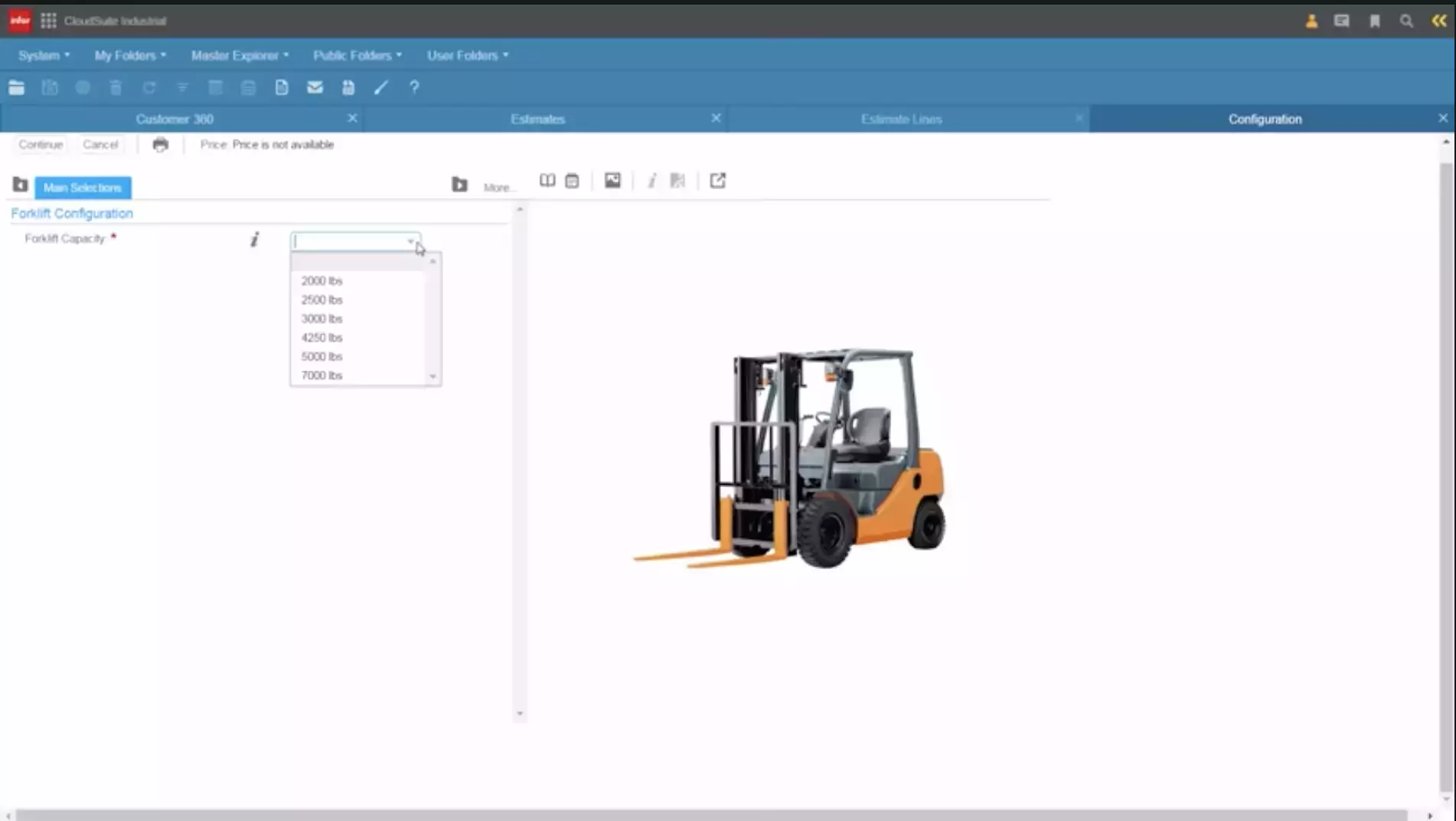

Infor CloudSuite Industrial (Syteline)

Infor offers industry-specific ERP solutions with MRP functionalities tailored for manufacturing industries. It includes features like demand planning, inventory management, and scheduling to optimize production processes and resource utilization.

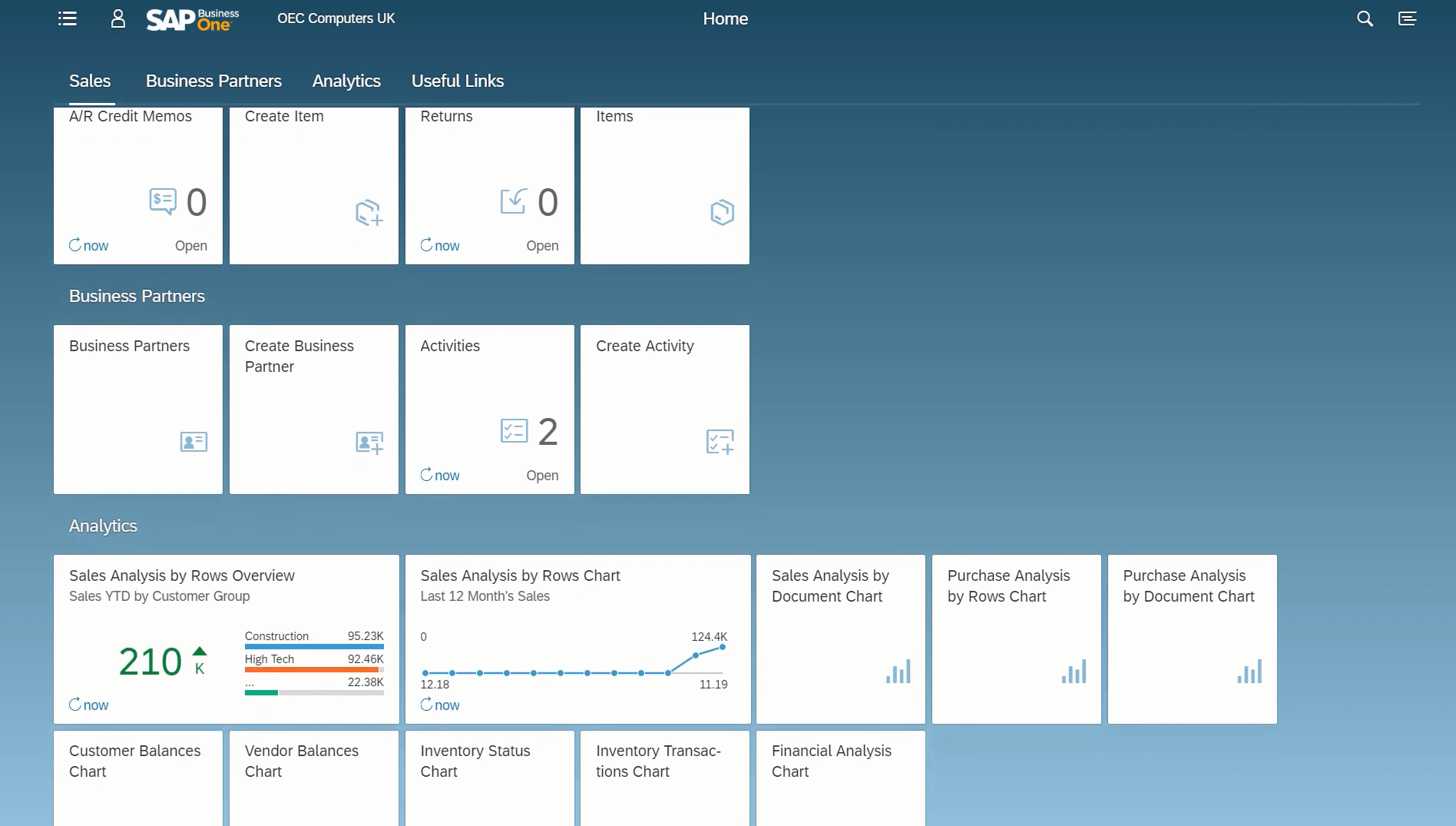

SAP Business One

SAP Business One is a comprehensive ERP software solution designed for small to mid-sized businesses. Its MRP module enables businesses to manage inventory effectively, optimize production planning, and streamline procurement processes.

Oracle Netsuite

NetSuite is a cloud-based ERP software suite that covers a wide range of business applications. It provides robust MRP features, including real-time visibility into production processes, inventory management, and demand planning, to drive manufacturing efficiencies.

Odoo

Odoo is an open source ERP platform which has been used by small and fast growing manufacturing organizations looking to unify their processes from shop floor to manufacturing execution and beyond.

SAP Business ByDesign

An integrated suite designed for mid-market businesses and subsidiaries of large corporations, SAP Business ByDesign offers strong MRP capabilities, including demand forecasting, production and inventory control, and efficient handling of the bill of materials.

Microsoft Dynamics Business Central

Microsoft Dynamics offers robust MRP functionality as part of its comprehensive ERP suite. It aids businesses in managing inventory, optimizing production schedules, and integrating with other processes like sales and finance for a streamlined workflow.

SYSPRO ERP

SYSPRO is a popular ERP solution for small business manufacturers in multiple industries, with a variety of process and discrete manufacturing capabilities.

Acumatica

Acumatica is a powerful Cloud based ERP system which is used by SMB and small business manufacturers around the world and provides deep manufacturing ERP capabilities.

IFS Applications

IFS Applications is a strong ERP solution for manufacturers in the small and medium sized business space and is used by worldwide brands.

Epicor

Epicor ERP caters to various industries with a focus on manufacturing. Its MRP capabilities include tools for managing production, scheduling, inventory, and procurement, ensuring that the right materials are available at the right time to meet production demands.

QAD Systems

QAD Systems is a popular ERP solution for small business manufacturers in multiple industries, with a variety of process and discrete manufacturing capabilities.

SYSPRO

SYSPRO is a strong ERP solution for manufacturers in the small and medium-sized business space and is used by worldwide brands to manage production, sales orders and supply chain management.

Global Shop Solutions

Global Shop Solutions is an ERP specificially designed for small and medium sized manufacturing companies and provides flexibility and deep production capabilities at a low cost - both On-Premise and in the Cloud.

MRP Software for Large Enterprises

What are some of the best ERP systems for large manufacturers? See our highlighted best ERP software solutions for large manufacturing companies below:

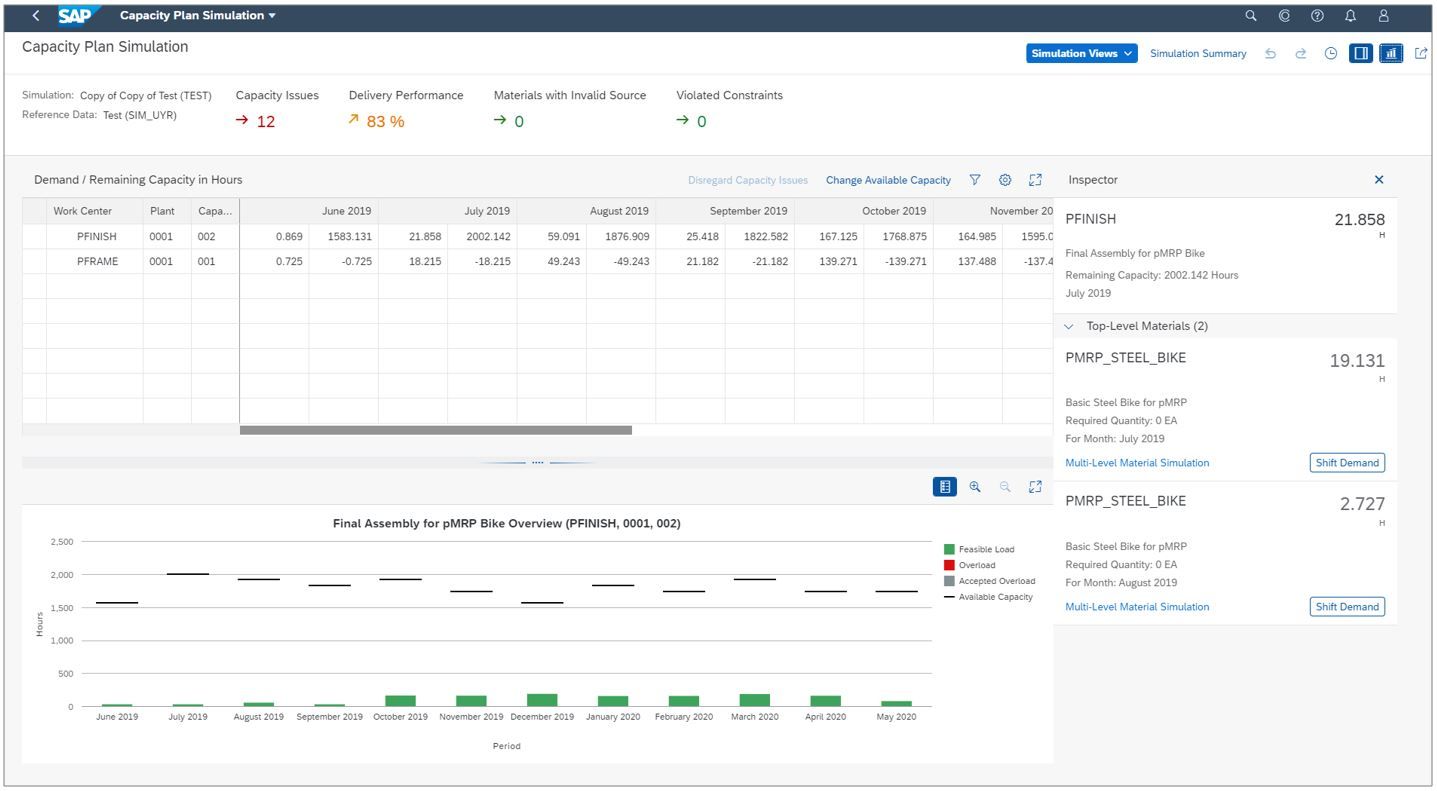

SAP S/4 HANA

SAP S/4 HANA for many is the gold standard MRP solution for large manufacturers. It provides deep industry capabilities for manufacturing and offers the largest customer base of global manufacturing organizations.

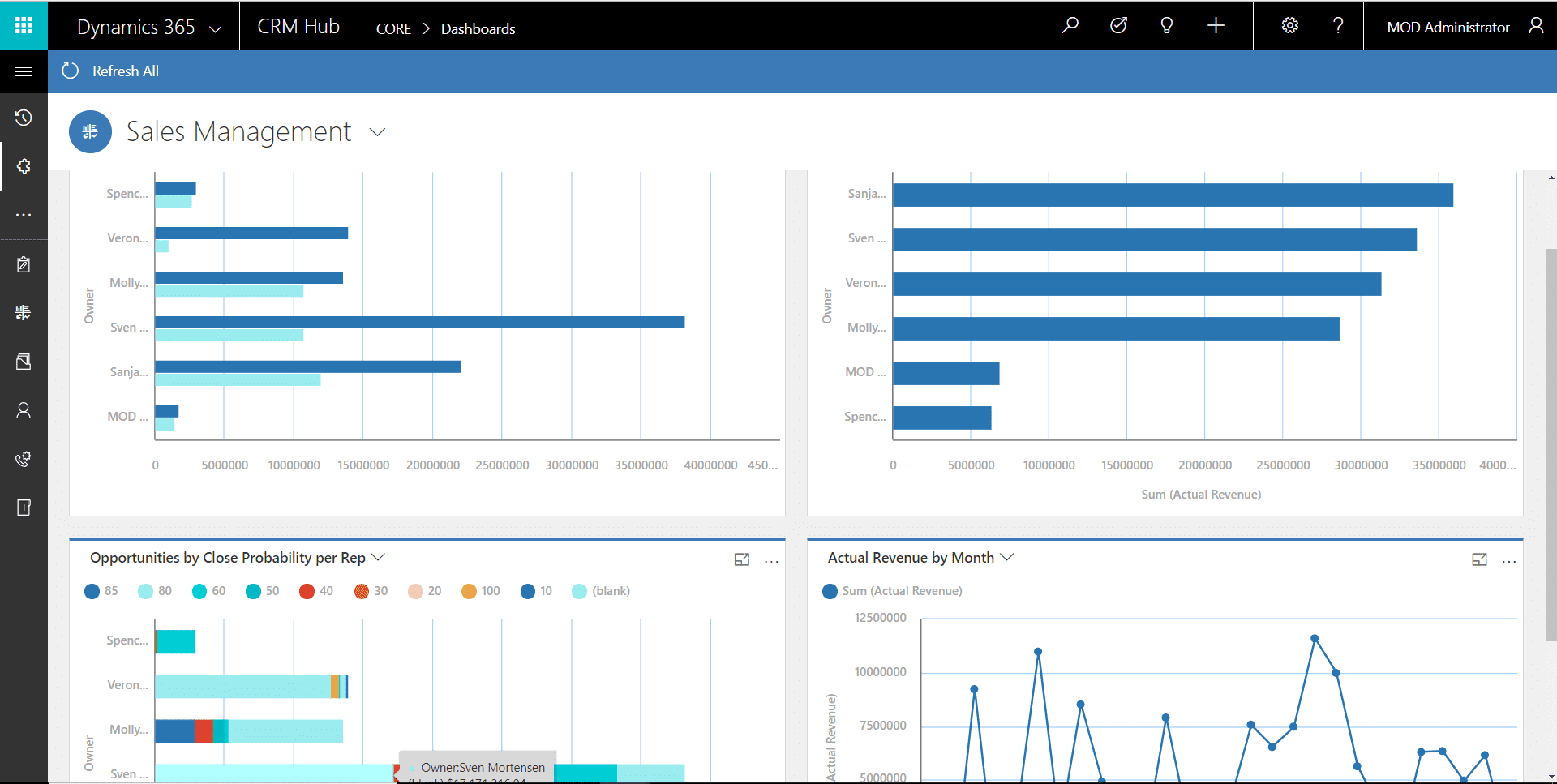

Microsoft Dynamics 365

Microsoft Dynamics 365 has become extremely popular with manufacturing organizations that need a greater degree of flexibility in their MRP system. Microsoft has also heavily invested in AI & ML capabilities to improve automation and efficiencies.

Oracle ERP Cloud

Oracle ERP Cloud is a comprehensive suite of cloud-based applications. The MRP functionality within Oracle ERP Cloud helps businesses forecast demand, efficiently manage inventories, streamline procurement processes, and optimize production schedules.

Manufacturing ERP Requirements Template

Speed up your ERP requirements gathering process with our free manufacturing ERP functional requirements template.

Best Cloud ERP for Manufacturing

What are some of the best Cloud ERP systems for manufacturers? See our highlighted best ERP software solutions for manufacturing that are Cloud based:

SAP S/4 HANA

SAP S/4 HANA is one of the best Cloud ERP & MRP for manufacturing and is used by many manufacturing companies in the food, discrete, automotive and other manufacturing industries. This Cloud ERP solution is available in private or public Cloud deployments.

Microsoft Dynamics 365

Microsoft Dynamics 365 is a robust Cloud ERP and MRP for manufacturing system which comes in several editions built for small and large businesses alike. Dynamics is one of the best Cloud ERP for manufacturing, available in both private and public Cloud.

Oracle ERP Cloud

Oracle ERP Cloud is a popular ERP solution amongst manufacturers, particularly in process industries. ERP Cloud offers integrated functionality across large enterprises including supply chain, production, HCM, financials and more.

SAP Business ByDesign

SAP Business ByDesign is a fully SaaS Cloud MRP for manufacturing solution that serves as a stable solution with over 30 out of the box processes for manufacturing firms.

Oracle Netsuite

Netsuite has become a popular MRP system choice for small and medium manufacturers that are looking for a Cloud based ERP system to manage growth across sales, production, supply chain, inventory and financials.

Infor CloudSuite Industrial (Syteline)

Infor CSI is a popular Cloud ERP solution for small and medium sized manufacturing companies in discrete and process manufacturing industries. See how Infor compares.

Infor CloudSuite Industrial

Infor CloudSuite Industrial, previously known as SyteLine, is an enterprise resource planning (ERP) solution that is designed to help manufacturers and distributors to improve productivity and respond faster to change. One of the significant modules within Infor CloudSuite Industrial is the Materials Requirements Planning (MRP) system.

-

Demand Forecasting and Planning: Infor CloudSuite Industrial MRP module allows you to manage demand by integrating sales forecasts with the manufacturing processes. This helps in better planning of production, inventory control, and resource allocation.

-

Master Production Scheduling (MPS): The MPS feature allows businesses to integrate multiple schedules, such as demand, production, and purchasing, into a master schedule. It ensures that resources are effectively allocated based on the prioritized demand.

-

Inventory Management: With the MRP module, businesses can optimize inventory levels, ensuring the right amount of stock is available to meet demand without excessive inventory costs. It includes functionality for managing multi-site inventory, tracking lot and serial numbers, and planning for obsolescence.

-

Bill of Materials (BOM) and Routing: The MRP software allows for detailed BOM and routing management. It ensures that all required materials, components, and sub-assemblies are available when needed for production.

-

What-if Scenario Analysis: Infor CloudSuite Industrial MRP supports what-if scenario analysis, enabling companies to model and evaluate potential changes in demand or supply chain disruptions before committing to any changes.

-

Supplier Relationship Management: The MRP module also helps in managing supplier relationships, tracking supplier performance, managing contracts, and ensuring timely delivery of materials.

-

Integrated Analytics and Reporting: Businesses can leverage built-in analytics and reporting tools to gain insight into MRP operations, such as understanding bottlenecks, predicting inventory needs, and assessing supplier performance.

-

Integration Capabilities: Infor CloudSuite Industrial MRP can integrate with other Infor solutions and third-party systems, providing a comprehensive solution for managing the supply chain.

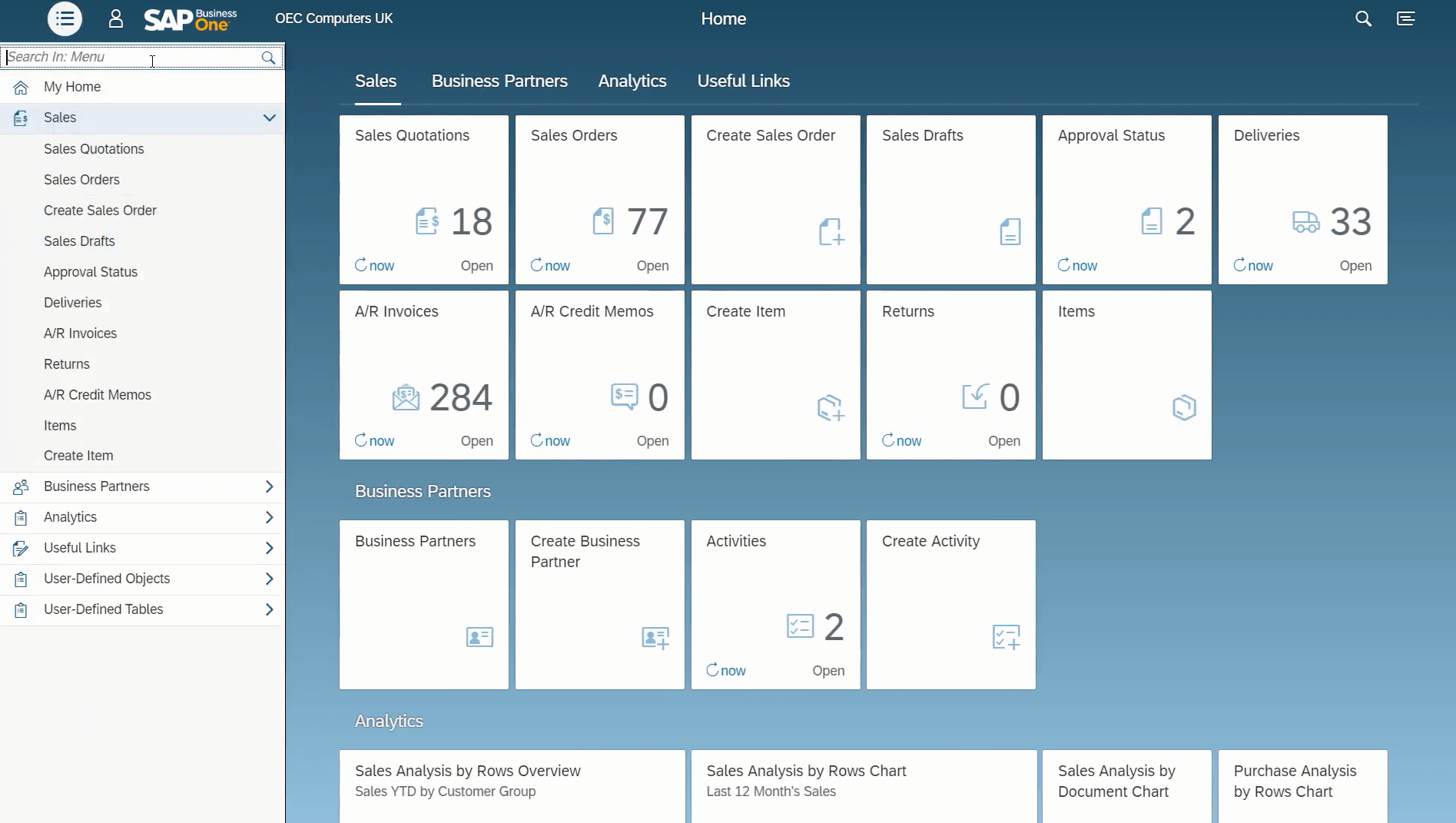

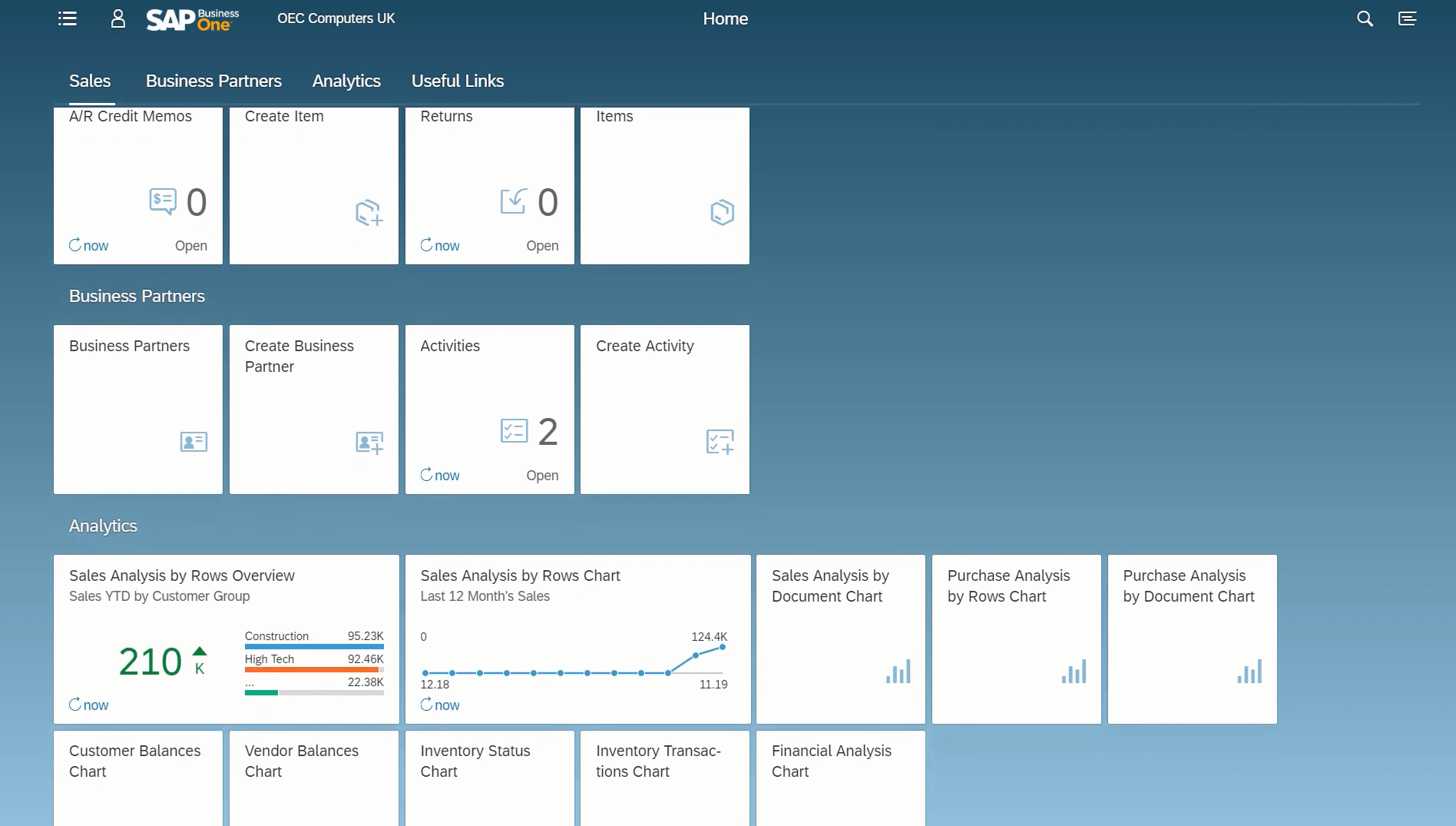

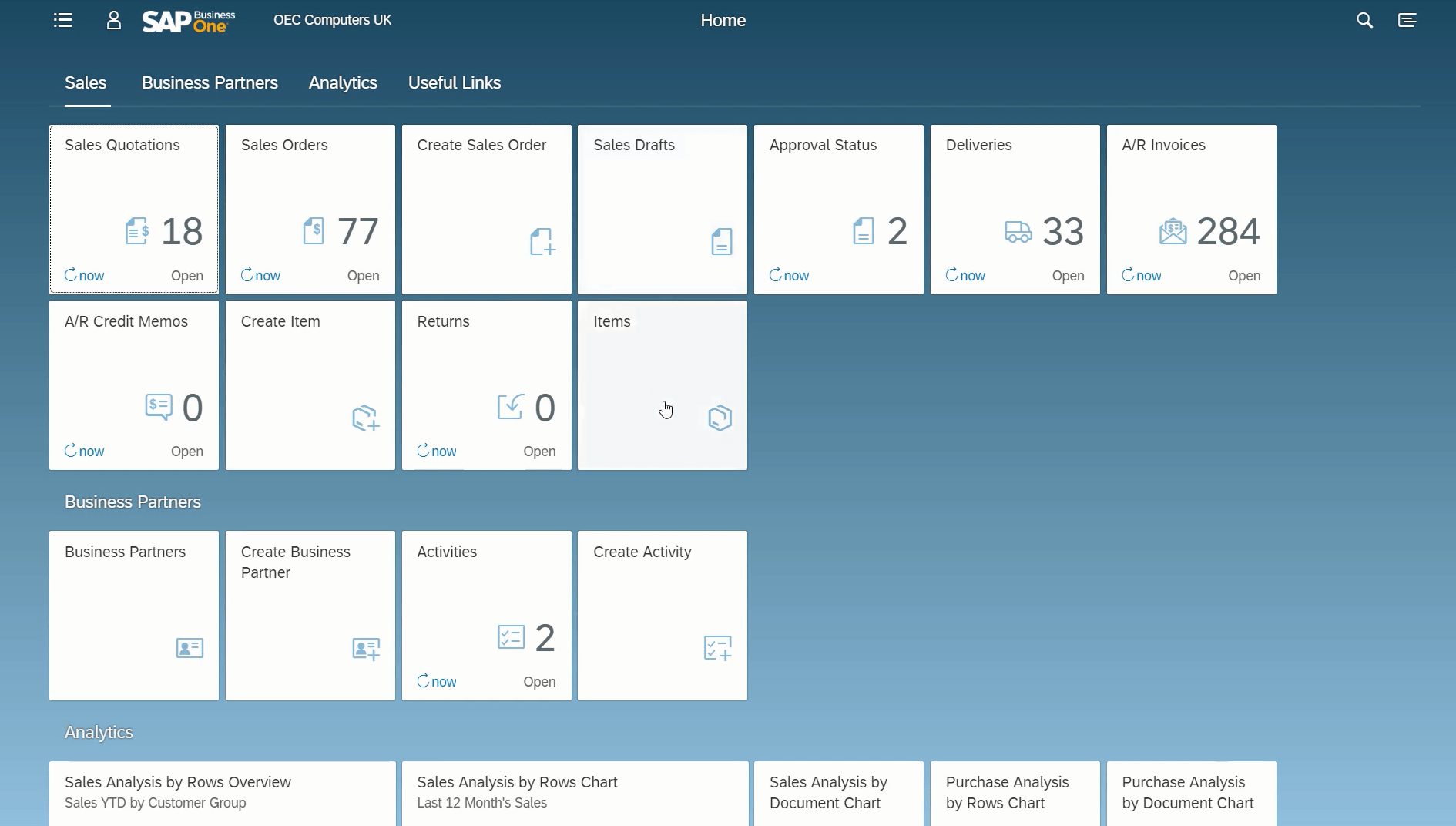

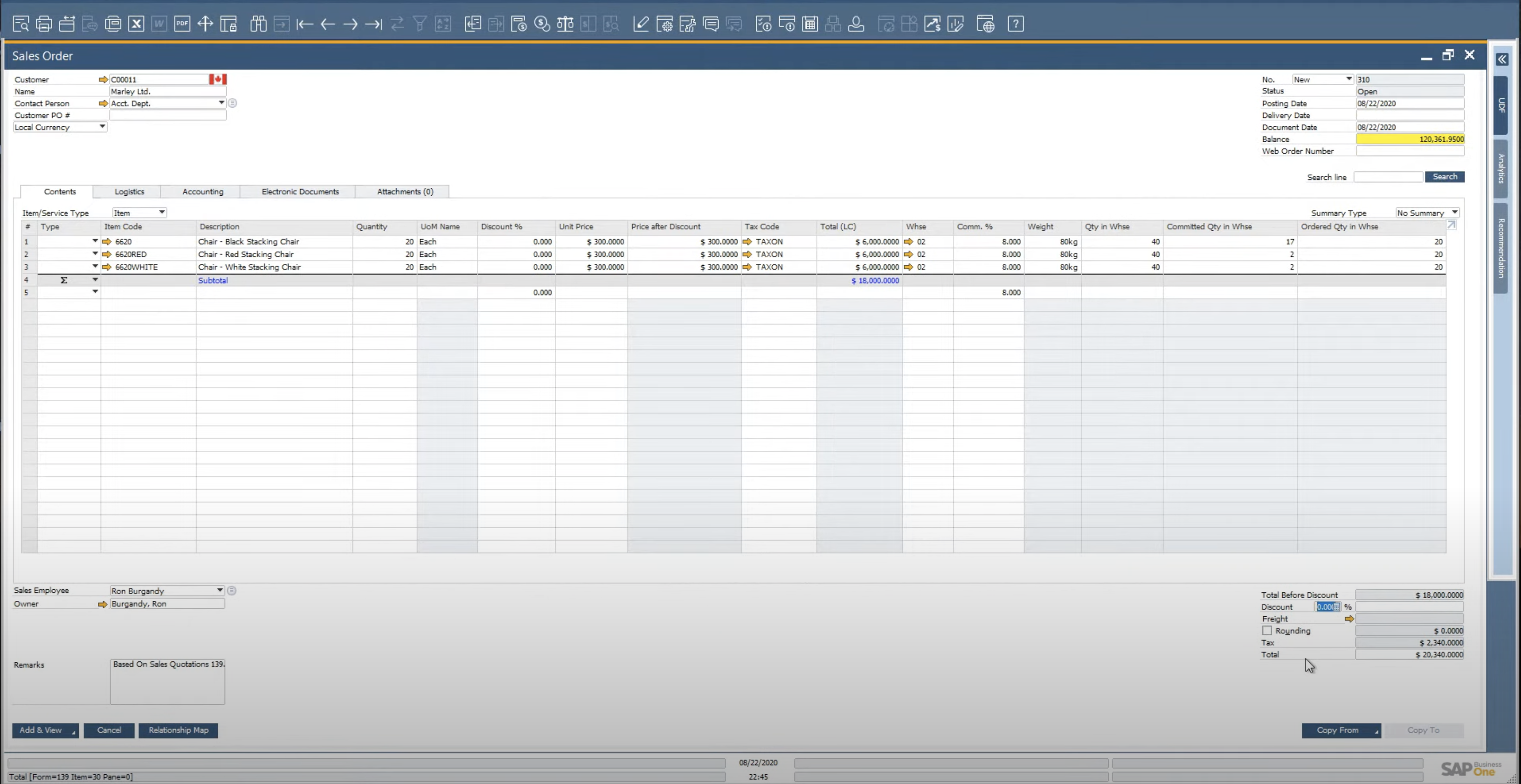

SAP Business One

SAP Business One is an integrated enterprise resource planning (ERP) solution designed for small and medium-sized businesses. It offers a suite of modules that cover all the main business functions, including an MRP (Materials Requirements Planning) module.

-

Demand Forecasting and Planning: SAP Business One's MRP system supports sales forecasting and ties this to material and production planning. It takes into account historical and current sales data to help predict future material and resource needs.

-

Master Production Scheduling: The system provides a tool for creating production and procurement schedules. It determines the most cost-effective and timely way to meet customer demand while considering resource and supplier constraints.

-

Inventory Management: SAP Business One MRP can effectively manage your inventory levels by planning and optimizing inventory supply through a series of MRP runs. This helps reduce costs and prevent shortages or excesses.

-

Bill of Materials (BOM) Management: BOM management is a part of the MRP offering, ensuring you have all the necessary components for production. BOMs can be managed for various product types, including standard, phantom, and sales BOMs.

-

What-if Scenario Analysis: What-if analysis tools allow you to predict the impact of certain scenarios on your supply chain and production processes. This supports better decision-making and risk mitigation.

-

Purchase and Production Orders: The MRP module can automatically generate purchase and production orders based on the analysis of current inventory levels, predicted demand, and predefined order minimums.

-

Data Visualization and Reporting: SAP Business One offers robust reporting and data visualization tools. These tools give companies insights into their MRP operations and aid in decision-making processes.

-

Integration Capabilities: SAP Business One MRP can be seamlessly integrated with other SAP Business One modules and third-party systems, ensuring a comprehensive approach to business management.

Epicor Kinetic

Epicor ERP is a comprehensive solution designed to meet the needs of businesses, especially in manufacturing and distribution. It offers several modules, including a robust Materials Requirements Planning (MRP) module.

-

Demand Forecasting and Planning: The MRP module in Epicor supports demand management by integrating sales forecasts with manufacturing processes. It provides insights into future needs and supports strategic decision making.

-

Master Production Scheduling (MPS): Epicor's MPS functionality is designed to ensure that sufficient materials, labor, and equipment will be available when needed, based on prioritized demand, while also considering material availability and capacity constraints.

-

Inventory Management: Epicor's MRP module helps manage inventory levels effectively, preventing shortages or overstock situations. It provides real-time visibility into inventory across multiple locations and includes features for lot and serial number tracking.

-

Bill of Materials (BOM) and Routing Management: Epicor's MRP software provides detailed BOM and routing management, ensuring that all necessary materials, components, and sub-assemblies are available when needed for production.

-

What-if Scenario Analysis: This module supports the analysis of potential scenarios, allowing you to evaluate the impact of changes in demand or supply chain disruptions before committing to these changes.

-

Supplier Relationship Management: The MRP module helps manage supplier relationships, offering tools for tracking supplier performance, managing purchase contracts, and ensuring on-time delivery of materials.

-

Integrated Analytics and Reporting: Epicor ERP's MRP module includes built-in analytics and reporting tools, providing insights into MRP operations, helping identify bottlenecks, predicting inventory needs, and assessing supplier performance.

-

Integration Capabilities: Epicor's MRP can integrate with other Epicor modules and third-party systems for a comprehensive supply chain management solution.

Acumatica

Acumatica is a cloud-based Enterprise Resource Planning (ERP) solution that serves small and medium-sized businesses across various industry sectors. One of its modules includes a robust Materials Requirements Planning (MRP) system.

-

Demand Forecasting and Planning: Acumatica's MRP system allows businesses to manage demand by integrating sales forecasts into their production planning. This feature helps in better planning of production schedules, inventory control, and resource allocation.

-

Master Production Scheduling (MPS): MPS in Acumatica enables the coordination of multiple schedules, including demand, production, and purchasing, into a master schedule. It ensures effective resource allocation based on demand priorities.

-

Inventory Management: Acumatica's MRP module can help businesses optimize their inventory levels to meet demand without carrying excessive stock. The system includes features for managing multi-site inventory, tracking lot and serial numbers, and planning for product obsolescence.

-

Bill of Materials (BOM) and Routing: Acumatica's MRP software includes detailed BOM and routing management. It ensures that all required materials, components, and sub-assemblies are available at the right time for production.

-

What-if Scenario Analysis: Acumatica supports the evaluation of potential scenarios, allowing companies to simulate and analyze changes in demand or supply chain disruptions before making any changes.

-

Supplier Relationship Management: The MRP module aids in managing supplier relationships, tracking supplier performance, managing contracts, and ensuring timely delivery of materials.

-

Integrated Analytics and Reporting: The system includes built-in analytics and reporting tools to provide insights into MRP operations, identify bottlenecks, predict inventory needs, and assess supplier performance.

-

Integration Capabilities: Acumatica's MRP system can integrate with other modules and third-party systems to provide a comprehensive supply chain management solution.

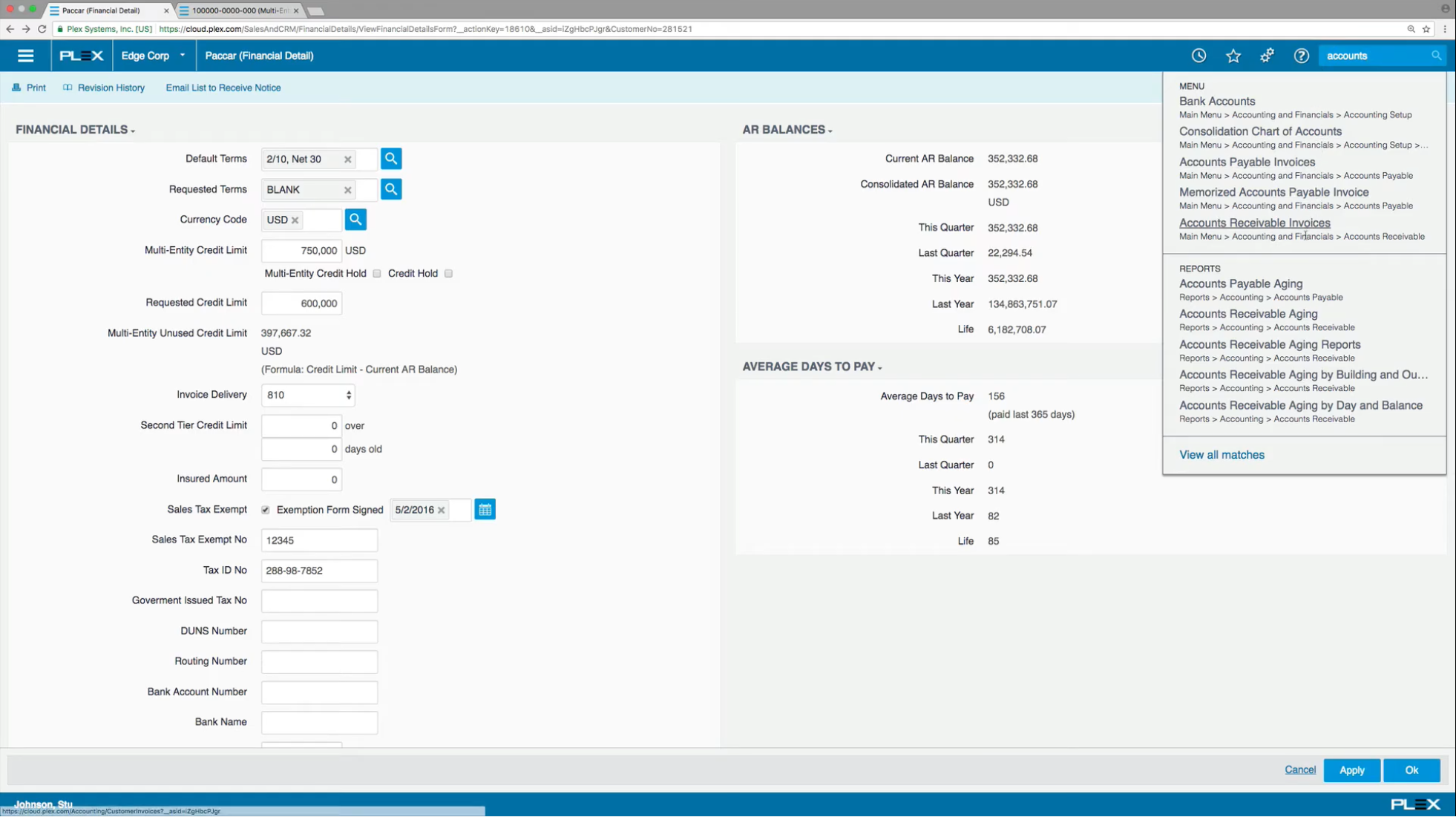

Plex Manufacturing Cloud

Plex Manufacturing Cloud is a cloud-based ERP (Enterprise Resource Planning) solution designed for manufacturing enterprises. It comes equipped with a robust Materials Requirements Planning (MRP) module that provides comprehensive production planning and scheduling capabilities.

-

Demand Forecasting and Planning: Plex MRP system can integrate sales forecasts into the manufacturing processes, allowing businesses to manage demand effectively. This aids in better planning of production, inventory control, and resource allocation.

-

Master Production Scheduling (MPS): Plex Manufacturing Cloud allows businesses to coordinate multiple schedules (such as demand, production, and purchasing) into a master schedule. It ensures that resources are efficiently allocated based on the prioritized demand.

-

Inventory Management: Plex's MRP module can help manage inventory levels to prevent shortages or excess stock. It supports multi-location inventory management and includes features for tracking lot and serial numbers.

-

Bill of Materials (BOM) and Routing Management: Plex provides detailed BOM and routing management, ensuring all necessary materials, components, and sub-assemblies are available when needed for production.

-

What-if Scenario Analysis: Plex's MRP module supports the evaluation of potential scenarios. Companies can simulate and analyze changes in demand or supply chain disruptions before making any changes.

-

Supplier Relationship Management: Plex aids in managing supplier relationships, tracking supplier performance, managing contracts, and ensuring timely delivery of materials.

-

Integrated Analytics and Reporting: Plex's MRP module includes built-in analytics and reporting tools to gain insight into MRP operations, identify bottlenecks, predict inventory needs, and assess supplier performance.

-

Integration Capabilities: Plex MRP can integrate with other Plex modules and third-party systems, offering a comprehensive solution for managing the supply chain.

SAP S/4 HANA

SAP S/4HANA is an intelligent ERP system designed to run in real-time with in-memory database technology, SAP HANA. The system is used by large corporations, as well as small and medium-sized enterprises, and provides various capabilities, including a Materials Requirements Planning (MRP) system.

-

Demand Forecasting and Planning: The MRP system in SAP S/4HANA allows for effective demand management by integrating sales forecasts with manufacturing processes, providing accurate predictions for future needs.

-

Master Production Scheduling (MPS): The MPS feature in SAP S/4HANA ensures that necessary materials, labor, and equipment will be available for production based on demand forecasts, while considering material availability and capacity constraints.

-

Inventory Management: SAP S/4HANA's MRP module helps manage inventory levels to prevent shortages or overstock situations. The system provides real-time visibility into inventory status across multiple locations and includes features for lot and serial number tracking.

-

Bill of Materials (BOM) and Routing Management: The MRP system provides detailed BOM and routing management, ensuring all required materials, components, and sub-assemblies are available when needed for production.

-

What-if Scenario Analysis: SAP S/4HANA's MRP module supports the evaluation of potential scenarios, allowing companies to simulate and analyze changes in demand or supply chain disruptions before making any changes.

-

Supplier Relationship Management: The MRP module aids in managing supplier relationships, tracking supplier performance, managing purchase contracts, and ensuring the timely delivery of materials.

-

Integrated Analytics and Reporting: SAP S/4HANA's MRP module includes built-in analytics and reporting tools that provide insights into MRP operations, identify bottlenecks, predict inventory needs, and assess supplier performance.

-

Integration Capabilities: The MRP system can integrate with other modules in SAP S/4HANA and third-party systems to provide a comprehensive solution for managing the supply chain.

Microsoft Dynamics 365

Microsoft Dynamics 365 is a suite of enterprise resource planning (ERP) and customer relationship management (CRM) applications designed to support a range of business functions. Within this suite, Dynamics 365 Supply Chain Management provides robust Materials Requirements Planning (MRP) capabilities.

-

Demand Forecasting and Planning: Dynamics 365 allows for efficient demand management by integrating sales forecasts with production planning. It supports better decision-making by providing insights into future requirements.

-

Master Production Scheduling (MPS): The system provides capabilities for coordinating multiple schedules such as demand, production, and purchasing into a master schedule. It ensures efficient resource allocation based on demand priorities.

-

Inventory Management: Dynamics 365 MRP can effectively manage inventory levels, ensuring that the right amount of stock is available to meet demand, while avoiding overstocking. It includes features for managing multi-site inventory and tracking lot and serial numbers.

-

Bill of Materials (BOM) and Routing Management: The MRP system provides detailed BOM and routing management. This ensures that all necessary materials, components, and sub-assemblies are available at the right time for production.

-

What-if Scenario Analysis: Dynamics 365 supports the evaluation of potential scenarios, allowing companies to simulate and analyze changes in demand or supply chain disruptions before making any changes.

-

Supplier Relationship Management: The MRP module aids in managing supplier relationships, tracking supplier performance, managing contracts, and ensuring the timely delivery of materials.

-

Integrated Analytics and Reporting: Dynamics 365 MRP includes built-in analytics and reporting tools to provide insights into MRP operations. It helps identify bottlenecks, predict inventory needs, and assess supplier performance.

-

Integration Capabilities: Dynamics 365 MRP can be integrated with other Dynamics 365 modules and third-party systems, providing a comprehensive solution for managing the supply chain.

SAP Business One

SAP Business One is an integrated enterprise resource planning (ERP) solution designed for small and medium-sized businesses. It offers a suite of modules that cover all the main business functions, including an MRP (Materials Requirements Planning) module.

-

Demand Forecasting and Planning: SAP Business One's MRP system supports sales forecasting and ties this to material and production planning. It takes into account historical and current sales data to help predict future material and resource needs.

-

Master Production Scheduling: The system provides a tool for creating production and procurement schedules. It determines the most cost-effective and timely way to meet customer demand while considering resource and supplier constraints.

-

Inventory Management: SAP Business One MRP can effectively manage your inventory levels by planning and optimizing inventory supply through a series of MRP runs. This helps reduce costs and prevent shortages or excesses.

-

Bill of Materials (BOM) Management: BOM management is a part of the MRP offering, ensuring you have all the necessary components for production. BOMs can be managed for various product types, including standard, phantom, and sales BOMs.

-

What-if Scenario Analysis: What-if analysis tools allow you to predict the impact of certain scenarios on your supply chain and production processes. This supports better decision-making and risk mitigation.

-

Purchase and Production Orders: The MRP module can automatically generate purchase and production orders based on the analysis of current inventory levels, predicted demand, and predefined order minimums.

-

Data Visualization and Reporting: SAP Business One offers robust reporting and data visualization tools. These tools give companies insights into their MRP operations and aid in decision-making processes.

-

Integration Capabilities: SAP Business One MRP can be seamlessly integrated with other SAP Business One modules and third-party systems, ensuring a comprehensive approach to business management.

| ERP Software | Modules and Functionality | Number of Customers | Number of Reviews | Minimum Cost | Deployment Options |

|---|---|---|---|---|---|

|

Oracle NetSuite |

Financial Management: General Ledger, Accounts Receivable, Accounts Payable, Fixed Assets, Revenue Recognition; Procurement: Purchase Orders, Vendor Management, Requisition Management, Inventory Management; Inventory Management: Inventory Control, Warehouse Management, Supply Chain Management; CRM: Sales Force Automation, Marketing Automation, Customer Service Management; HR: Employee Records, Time and Expense Tracking, Payroll Management; Ecommerce: Web Storefront, Order Management, Payment Processing | 24,000+ | 970 | $999/month | Cloud |

|

SAP Business One |

Financial Management: General Ledger, Accounts Payable, Accounts Receivable, Fixed Assets; Sales and Customer Management: Sales Orders, Invoicing, Opportunities, Customer Management; Inventory Management: Inventory Control, Goods Receipts and Issues, Production Orders; Purchasing: Purchase Orders, Vendor Management; Analytics and Reporting: Dashboards, KPIs, Crystal Reports; Service Management: Service Contracts, Service Calls, Customer Management; HR: Employee Records, Time Tracking, Payroll | 70,000+ | 860 | $1,500/year | Cloud or On-Premise |

|

Microsoft Dynamics 365 BC |

Financial Management: General Ledger, Accounts Payable, Accounts Receivable, Fixed Assets; Sales and Marketing: Sales Orders, Invoicing, Opportunities, Campaign Management, Customer Management; Purchasing and Inventory: Purchase Orders, Vendor Management, Inventory Control, Warehouse Management; HR: Employee Records, Time and Expense Tracking, Payroll Management; Manufacturing: Bill of Materials, Production Orders, Capacity Planning; Service Management: Service Contracts, Service Orders, Customer Management; Analytics and Reporting: Dashboards, KPIs, Power BI | 200,000+ | 1,030 | $70/user/month | Cloud or On-Premise |

|

Infor CloudSuite Industrial |

Financial Management: General Ledger, Accounts Payable, Accounts Receivable, Fixed Assets; Supply Chain Management: Inventory Control, Warehouse Management, Demand Planning, Procurement; Human Capital Management: Employee Records, Time and Attendance, Payroll Management, Benefits Administration; Project Management: Resource Management, Time and Expense Tracking, Budgeting | 68,000+ | N/A | N/A | Cloud |

|

Epicor ERP |

Financial Management: General Ledger, Accounts Payable, Accounts Receivable, Fixed Assets, Cash Management; Production Management: Bill of Materials, Job Costing, Quality Management, Manufacturing Execution, Production Planning and Scheduling; Supply Chain Management: Inventory Control, Purchase Management, Materials Requirement Planning, Supplier Relationship Management; Sales Management: Sales Orders, Pricing, Quotes, Order Management; Service Management: Service Orders, Contracts, Warranty Management | 20,000+ | 490 | N/A | Cloud or On-Premise |

|

Plex ERP |

Manufacturing Execution System (MES): Production Control, Quality Management, Shop Floor Integration; Supply Chain Management: Inventory Control, Purchasing, Shipping and Receiving, Demand Planning; Financial Management: General Ledger, Accounts Payable, Accounts Receivable, Fixed Assets, Cash Management; Sales Management: Sales Orders, Pricing, Quotes, Order Management; Human Capital Management: Employee Records, Time and Attendance, Payroll Management, Benefits Administration | ||||

| Acumatica | Financial Management, CRM, Distribution Management, Manufacturing Management, Project Accounting, Field Service, E-Commerce | 6,000+ | 600+ | $12,000/year | Cloud, On-Premises |

| Sage X3 | Financial Management, Supply Chain Management, Manufacturing Operations, CRM, HR Management, Business Intelligence, E-Commerce | 7,000+ | 400+ | $30,000/license | Cloud, On-Premises |

| SYSPRO | Financial Management, CRM, Distribution Management, Manufacturing Management, E-Commerce, Human Resources, Business Intelligence | 15,000+ | 500+ | $20,000/license | Cloud, On-Premises |

| SAP Business ByDesign | Financial Management, CRM, HR Management, Project Management, Manufacturing Management, E-Commerce, Supply Chain Management, Analytics | 4,000+ | 200+ | $20,000/year | Cloud |

| Odoo | Financial Management, CRM, Manufacturing Management, E-Commerce, Project Management, HR Management, Website Builder, Inventory Management, Marketing Automation, POS | 50,000+ | 2,000+ | $6/user/month | Cloud, On-Premises |

| QAD ERP | Financial Management, Manufacturing Management, Supply Chain Management, CRM, E-Commerce, Analytics, Demand and Supply Planning, Quality Management, Asset Management | 2,000+ | 100+ | $40,000/license | Cloud, On-Premises |

What is the best ERP for manufacturing in 2021?

We review the best ERP software for manufacturing? We compare and rank the best ERP software for manufacturers in 2021 including SAP Business One, Netsuite, Infor & more.

ERP Requirements Gathering (RFI, RFP) Template Excel

Start your ERP evaluation process with our RFI & RFP Excel template for the engineering industry.

ERP Project Budget Calculator Template

Calculate the costs of your manufacturing ERP project with our prebuilt budget calculator.

Manufacturing Requirements Planning Modules & Functionality

Demand Forecasting: MRP systems use sophisticated algorithms and trend analysis to predict future demand accurately. For instance, an outdoor gear company can use these tools to understand the seasonal patterns in their sales. By identifying peaks in demand for hiking gear during summer months and snow gear in the winter, the company can adjust its production schedule months in advance to meet expected demand, improving efficiency and customer satisfaction.

Master Production Scheduling (MPS): MPS in MRP systems can provide a detailed plan for manufacturing each product. For example, in an automobile factory, the MPS will determine the quantity and production schedule for each part such as engine assemblies, bodywork, interior fitting, etc. This allows the company to optimize their workflow, ensuring that each product component is ready exactly when it's needed in the assembly line.

Inventory Management: This feature can offer real-time tracking of all inventory in the system. In a pharmaceutical manufacturing company, for instance, an MRP system can monitor the quantities of active ingredients and packaging materials in stock. When inventory levels drop below predetermined thresholds, the system can automatically trigger reordering, ensuring that production isn't delayed due to missing ingredients.

Bill of Materials (BOM) Management: In an MRP system, the BOM provides a hierarchical arrangement of all components and raw materials needed to produce a finished product. For example, an electronics manufacturer may have a BOM that includes specific electronic components, circuit boards, casing, screws, and packaging materials for a smartphone. The BOM Management ensures that every single part needed is accounted for before production begins, reducing the chances of production halt due to missing components.

Production Planning: MRP systems use demand forecasts and current inventory data to plan an efficient production schedule. In a beverage company, production planning can help coordinate the procurement of raw materials (such as fruits, sugar, and water), schedule production batches to optimize use of machinery, and manage inventory of finished goods to ensure freshness and timely delivery.

Procurement and Purchase Order Management: This feature streamlines the purchasing process. In a book publishing company, for example, the MRP system can track the usage rate of paper and ink. Once the inventory reaches the reorder point, the system can automatically generate a purchase order to the supplier, ensuring that there are no delays in the printing process due to lack of supplies.

Capacity Planning: An MRP system takes into account every detail of the company's resources, including machinery, labor, and supplier capacity. For instance, a furniture company can use capacity planning to adjust their production schedule based on the availability of wood from their suppliers, the capacity of their woodworking machines, and the number of available staff, optimizing their use of resources and reducing waste.

Supplier Relationship Management: This feature helps manage supplier details, contracts, and performance. For a clothing retailer, for example, this feature can help track which suppliers consistently provide high-quality fabrics on time, negotiate better terms with preferred suppliers, and quickly find replacement suppliers if needed.

What-if Scenario Analysis: This feature is particularly useful in volatile markets or during unforeseen events. For example, a food processing company could use this feature during a drought to simulate how a decrease in the availability of certain crops would impact their production, allowing them to adjust their production plans and seek alternate ingredients if necessary.

Reporting and Analytics: Detailed reports can provide insights into various aspects of production, from cost analysis to productivity metrics. For example, a cosmetic manufacturer can use these reports to identify the most expensive components in their products, potentially prompting a search for cheaper alternatives or a renegotiation of supplier contracts.

MRP Software FAQ

What is MRP software? MRP (Material Requirements Planning) software is a tool used in manufacturing processes to schedule and manage inventory and production. It helps to efficiently manage resources, track inventory levels, and plan future production based on current sales trends and forecasts.

How does MRP software work? MRP software takes into account the demand forecast for a product, the present inventory levels, supplier lead times, and the bill of materials (BOM) to determine the quantity and timing of each step in the production process.

What are the key features of MRP software? The key features of MRP software include inventory management, production planning, scheduling, demand forecasting, BOM management, and analytics/reporting.

Who uses MRP software? MRP software is mainly used by manufacturing companies of all sizes across various industries. It is particularly useful for businesses that need to manage complex production processes and multiple raw materials.

What are the benefits of using MRP software? The benefits of using MRP software include reduced inventory costs, improved production efficiency, enhanced customer service through better delivery performance, and increased transparency in the production process.

How is MRP software different from ERP software? MRP is typically a component of ERP (Enterprise Resource Planning) software. While MRP focuses specifically on production planning and inventory control, ERP systems provide a more comprehensive solution, including modules for human resources, finance, customer relationship management, and more.

Can MRP software integrate with other systems? Yes, many MRP systems can integrate with other enterprise systems such as ERP, SCM (Supply Chain Management), CRM (Customer Relationship Management), and accounting software. The level of integration depends on the software provider.

What should I consider when selecting MRP software? When selecting MRP software, consider your business size, industry, specific needs, budget, and the software's ease of use, scalability, customization options, integration capabilities, and the vendor's customer support.

Is there training provided for MRP software? Most MRP software providers offer comprehensive training, including user manuals, tutorials, webinars, and sometimes even on-site training. This can be clarified with the vendor during the purchasing process.

How secure is my data with MRP software? The security of your data depends on the MRP software provider. Reputable providers usually have robust security measures in place, such as encryption, access controls, and regular data backups. Always ask the vendor about their security measures before purchasing the software.

Can MRP software assist with regulatory compliance? Yes, MRP software can help maintain records, control processes, and provide detailed reports, all of which can be useful for demonstrating compliance with industry-specific regulations. However, it's important to ensure that the MRP software you choose meets your specific regulatory needs.

Can MRP software handle multiple manufacturing sites? Yes, many advanced MRP systems can handle multiple manufacturing sites, allowing you to track inventory, plan production, and manage resources across all your facilities. This feature may be particularly important for large or rapidly growing businesses.

Start Your ERP Journey With ERP Research

We help manufacturing firms to prepare for ERP change by guiding them through each stage of the process:

-

Build An ERP Business Case 2-3 weeksA solid business case is a foundation you need if you are going to persuade your organization to consider enterprise resource planning (ERP) implementation. Download Business Case Template

-

Compare ERP Vendors 2-3 weeksIt’s critical to understand which ERP vendor is right for your business. Before you decide on the vendor for your company, take a look at our solution pages to find out which vendor would be best. Compare ERP Vendors

-

Get Pricing Estimates 1-2 weeksOur exclusive process removes all the salesmen from the equation and gets you real pricing estimates from every qualified vendor. Contact Us For Pricing

-

Organize A Solution Demo 1-2 weeksDuring a demo, you will learn about how large corporations are making use of ERP software and how they are improving their business practices. Book A Demo

-

Build ERP Requirements 3-4 weeksIf you're looking to buy an Enterprise Resource Planning (ERP) system or upgrade your internal systems you will need a clear definition of all the functions, features and capabilities that you expect. You can approach this challenge by building what's called an ERP requirements document. Download ERP Requirements Template

-

Shortlist 4-8 Vendors 1 weekOne of the most important phases in the ERP project lifecycle is selecting the right software vendor. Ideally, you should shortlist 4-8 vendors - based on their credentials and your requirements. Contact Us To Shortlist Vendors

.png?width=278&name=sap-s-4hana-logo%20(2).png)