ERP for Medical Devices

ERP for medical devices manufacturing and distribution enables Class 1, Class 2 and Class 3 medical devices manufacturing companies to stay compliant, assure quality and drive efficiencies to improve patient outcomes.

At ERP Research we provide independent advice and analysis for medical devices ERP systems.

Top 10 ERP Software Report

Get our free in depth comparison of the Top 10 ERP solutions available on the market including Netsuite, Acumatica, Oracle, SAP and more.

Medical Devices ERP for Small Businesses

ERP software for Medical Device companies that are small and midsized need to strike a fine balance between depth of functionality and cost. Below are some ERP solutions for medical devices companies in the SMB space:

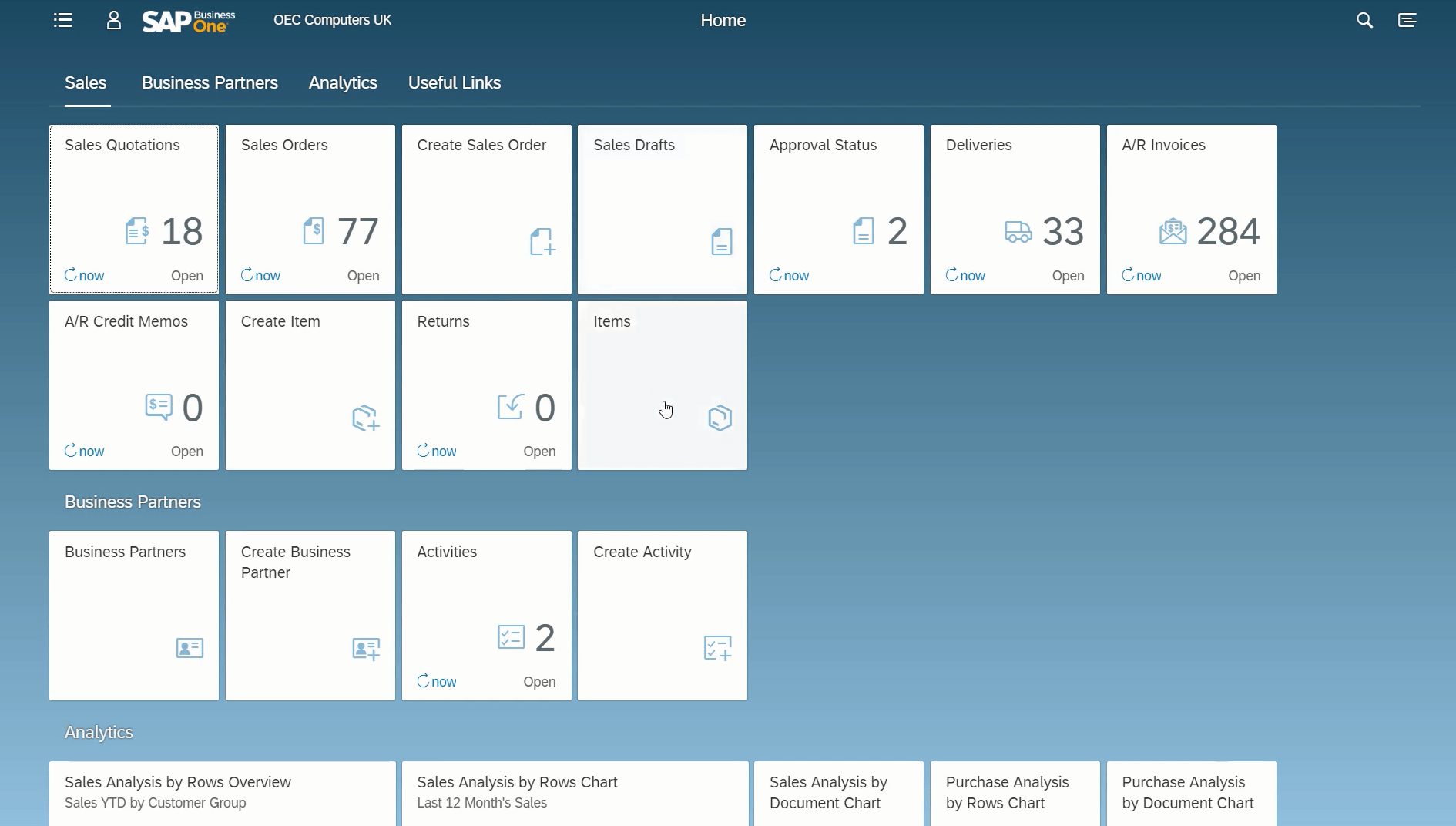

SAP Business ByDesign

SAP Business ByDesign is a Cloud ERP solution which has earned many growing customers in the medical devices manufacturing industry with its integrated suite of functionality spanning sales, production, inventory, quality and serialisation & batch traceability.

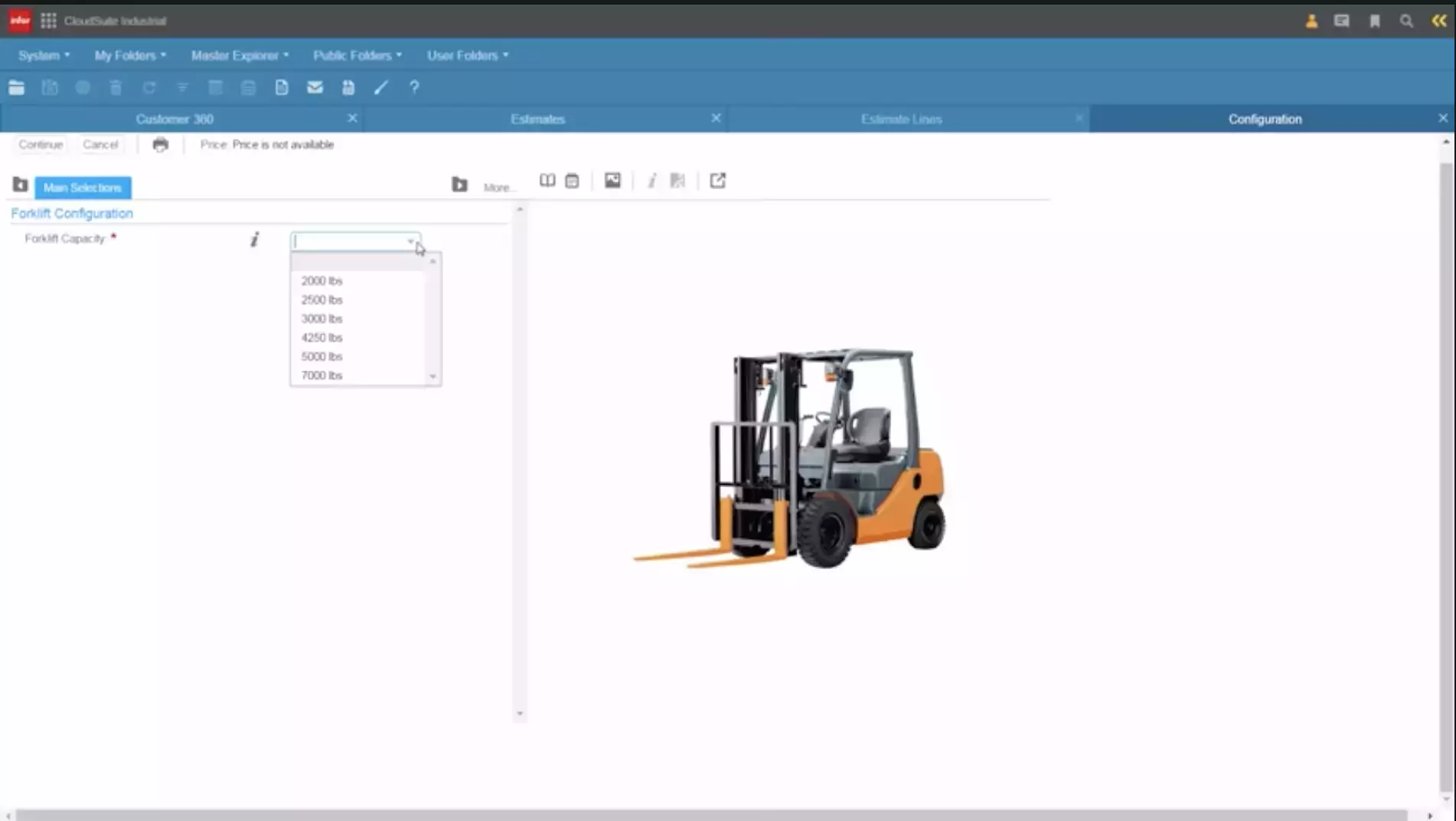

Infor CloudSuite Industrial (Syteline)

Infor CSI is well suited to small and medium sized medical device companies looking for a flexible ERP solution. Infor ERP provides tight integration between key business functions with a depth of functionality for pharmaceuticals.

Oracle Netsuite

Oracle Netsuite has been the ERP for many medical device manufacturing and distribution companies in growth. Netsuite provides a range of functionality enabling medical devices companies integrated financials, supply chain, manufacturing and inventory management.

Acumatica

Acumatica is a Cloud ERP solution which has earned many growing customers in the medical devices manufacturing industry with its integrated suite of functionality spanning sales, production, inventory, quality and serialisation & batch traceability.

Epicor

Epicor is well suited to small and medium sized medical device companies looking for a flexible ERP solution. Epicor ERP provides tight integration between key business functions with a depth of functionality for pharmaceuticals.

Microsoft Dynamics 365 Business Central

Microsoft Dynamics 365 Business Central is the SMB ERP of choice for smaller medical devices manufacturers. The solution streamlines manufacturing, financial management, quality and more.

Medical Devices ERP Systems for Large Companies

ERP for medical devices companies that are already well established brings more functionality and greater flexibility.

Below are popular ERP systems for medical device manufacturing and distribution companies that operate at scale, globally:

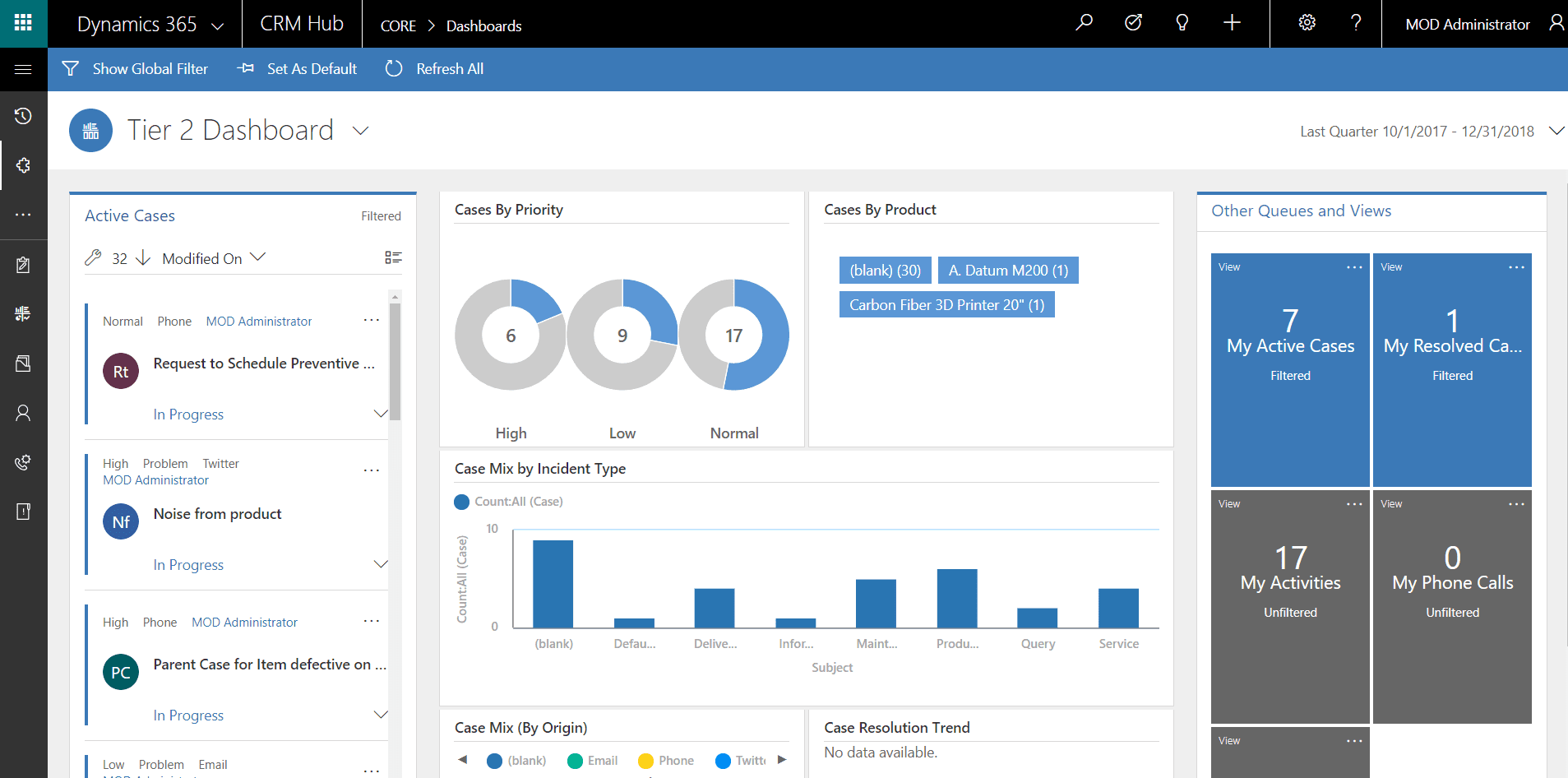

Microsoft Dynamics 365

Many medical devices companies are beginning to explore Microsoft Dynamics as their medical device manufacturing ERP. The solution provides a great degree of flexibility plus a large partner ecosystem that has developed many pharmaceutical industry add-ons.

Oracle ERP Cloud

Oracle ERP Cloud is a growing solution for life sciencesl companies searching for an ERP solution. With one end to end platform, Oracle ERP Cloud sets the foundation for strong finance and operations capabilities plus HCM and much more.

Best Cloud ERP for Medical Devices Industry

ERP for medical devices companies that are already well established brings more functionality and greater flexibility.

Below are popular ERP systems for medical device manufacturing and distribution companies that operate at scale, globally:

Oracle ERP Cloud

Oracle ERP Cloud is a growing solution for medical devices companies searching for an ERP solution. With one end to end platform, Oracle ERP Cloud sets the foundation for strong finance and operations capabilities plus HCM and much more.

SAP Business ByDesign

SAP Business ByDesign is a Cloud ERP solution which has earned many growing customers in the medical devices manufacturing industry with its integrated suite of functionality spanning sales, production, inventory, quality and serialisation & batch traceability.

SAP S/4 HANA

SAP S/4 HANA and its predecessors are synonymous with ERP for medical devices. S/4 ERP provides growing and large medical devices companies everything they need for finance, procurement, quality, manufacturing and traceability.

Infor CloudSuite Industrial (Syteline)

Infor CSI is well suited to small and medium sized medical device companies looking for a flexible ERP solution. Infor ERP provides tight integration between key business functions with a depth of functionality for pharmaceuticals.

QAD Systems

QAD is well suited to medium and large sized medical device companies looking for a flexible ERP solution. Infor ERP provides tight integration between key business functions with a depth of functionality for pharmaceuticals.

Infor CloudSuite Industrial (CSI) is an enterprise resource planning (ERP) software designed to support various industries, including manufacturing. Although not specifically tailored for medical device manufacturing, it can be customized and configured to cater to the unique needs of this industry. By leveraging its features and functionalities, medical device manufacturers can streamline their operations, ensure regulatory compliance, and enhance overall productivity. Here's how Infor CloudSuite Industrial can be used as medical device manufacturing software:

-

Product Lifecycle Management (PLM): CSI can help medical device manufacturers manage the entire product lifecycle, from concept to design, production, and disposal. This includes managing product data, engineering change orders, and version control, which are critical for traceability and compliance in the medical device industry.

-

Quality Management: Medical device manufacturers must adhere to strict quality standards and regulations, such as ISO 13485 and FDA 21 CFR Part 820. CSI provides built-in quality management tools that can help organizations establish, maintain, and monitor quality systems, including nonconformance tracking, corrective and preventive actions (CAPA), and audit management.

-

Production Planning and Scheduling: CSI can optimize production planning and scheduling by analyzing demand, capacity, and inventory levels. This helps medical device manufacturers improve on-time delivery, reduce lead times, and minimize inventory carrying costs.

-

Supply Chain Management: The software enables manufacturers to manage their supply chain more effectively, with features such as supplier management, procurement, and demand planning. This helps ensure the availability of critical components and materials, reducing the risk of production delays.

-

Regulatory Compliance: CSI can be configured to capture and store critical data needed for regulatory compliance, such as device history records (DHRs) and unique device identifiers (UDIs). It also supports electronic signatures and document control, which are essential for maintaining FDA compliance.

-

Serialization and Traceability: Medical device manufacturers must be able to track and trace their products throughout the supply chain. CSI can support serialization and traceability requirements by capturing and managing critical data, such as lot and serial numbers, throughout the manufacturing process.

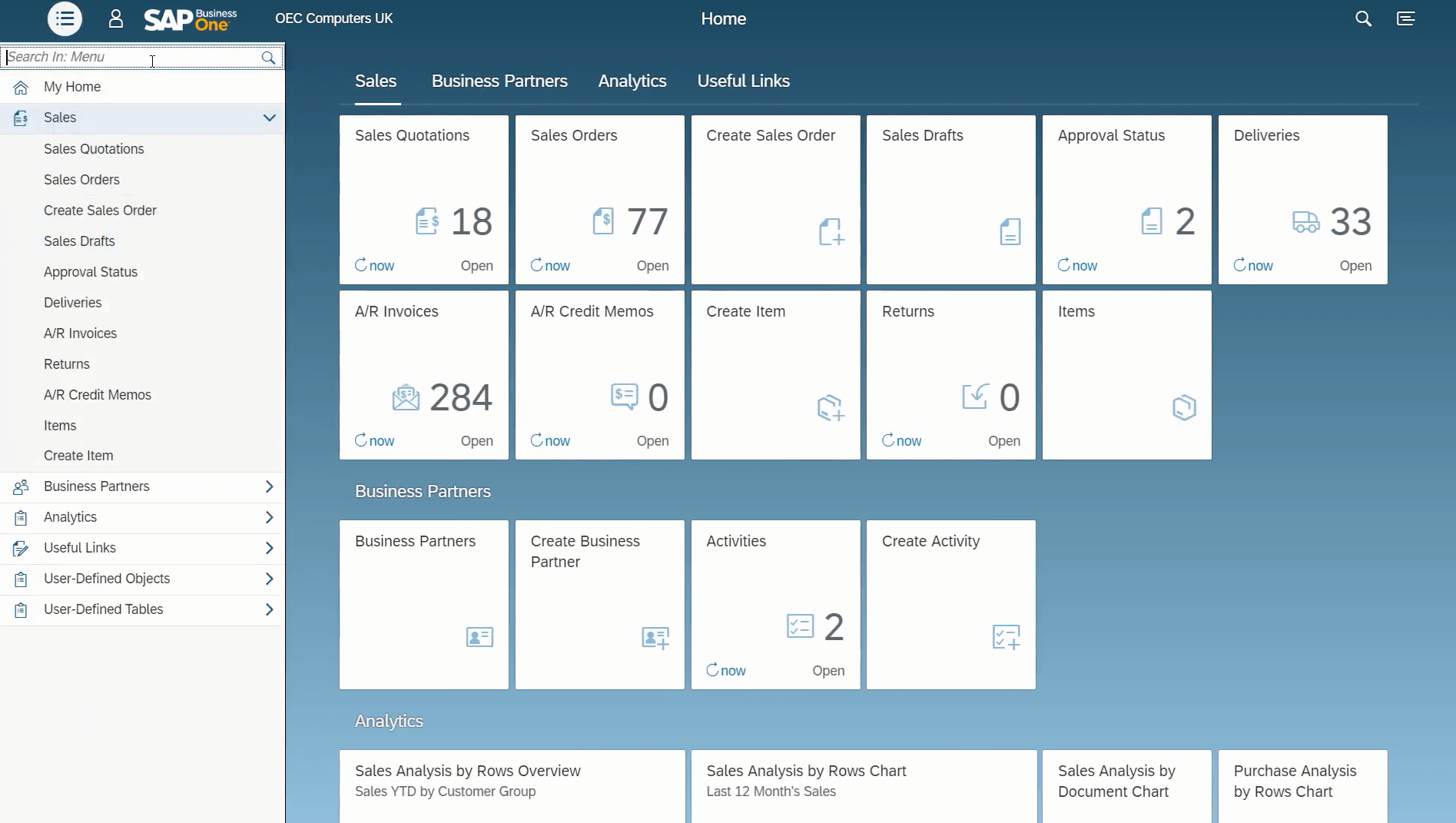

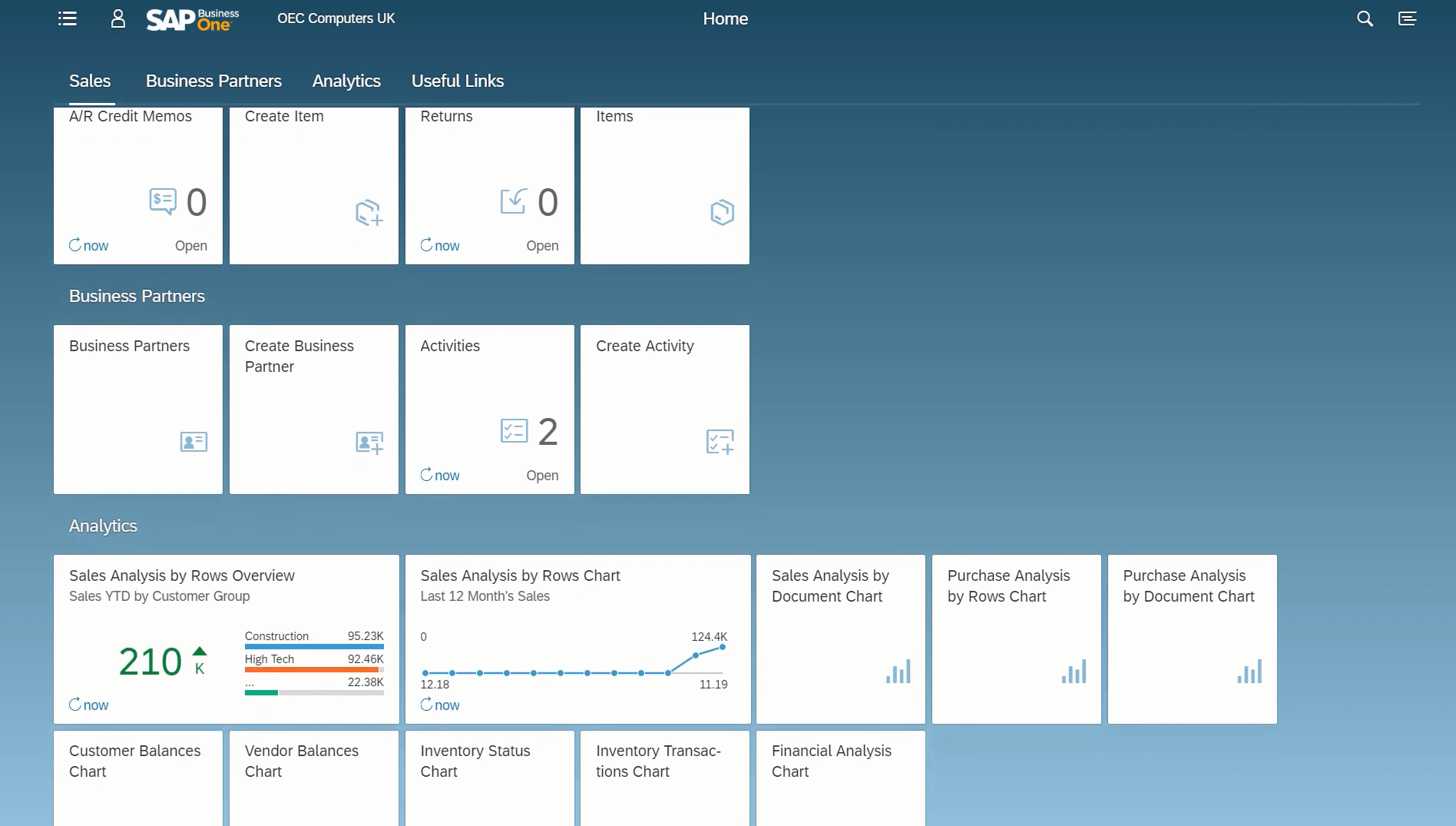

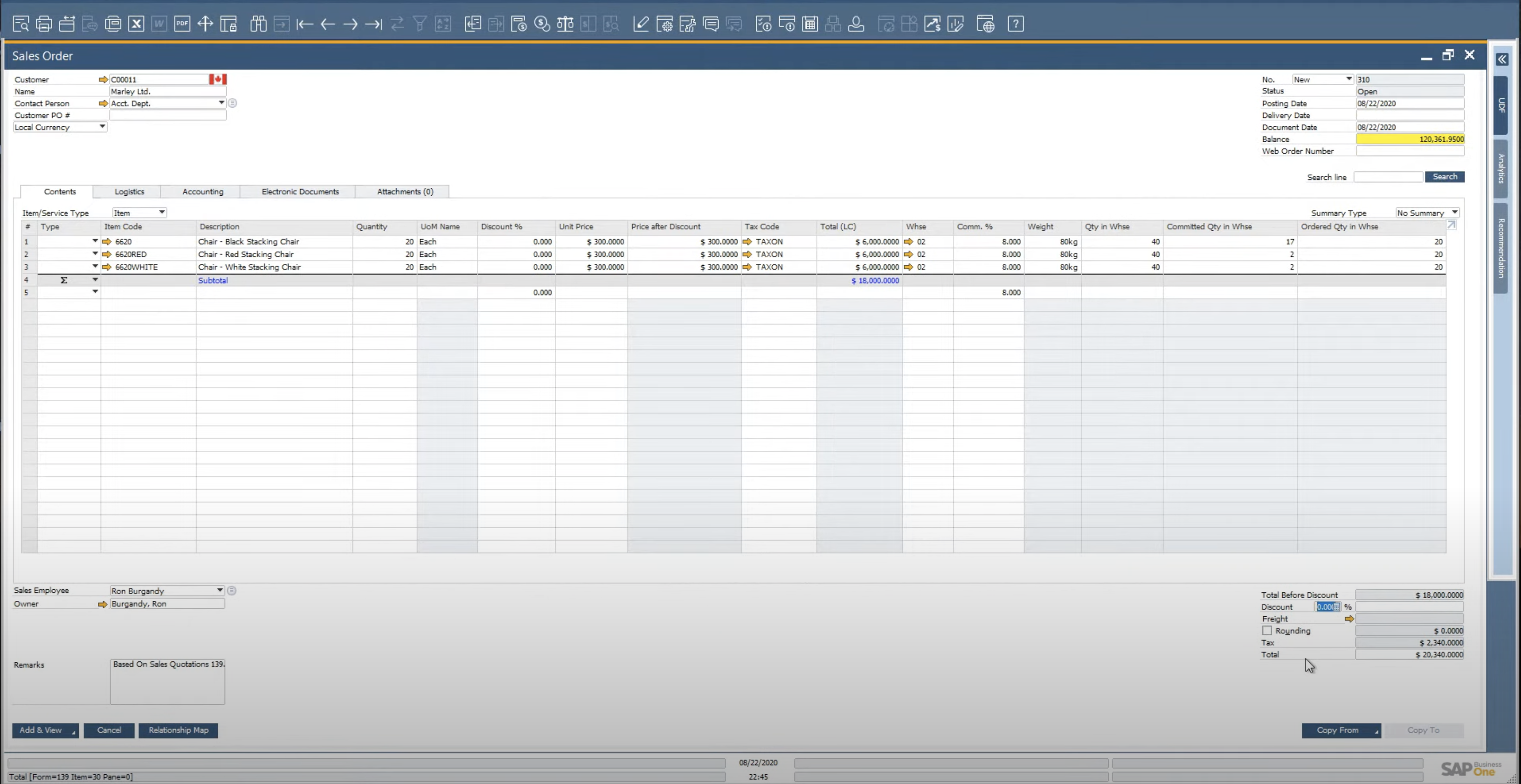

SAP Business One

SAP Business One is a comprehensive Enterprise Resource Planning (ERP) software that can be customized to cater to various industries, including medical device manufacturing. By leveraging SAP Business One's core features and implementing industry-specific add-ons, the software can be tailored to meet the unique requirements of medical device manufacturers. Here are some ways SAP Business One can be utilized as medical device manufacturing software:

-

Inventory and Warehouse Management: SAP Business One can help manage inventory levels, track stock movements, and optimize warehouse organization. For medical device manufacturers, this ensures efficient handling of raw materials, components, and finished products while maintaining quality control.

-

Quality Management: Medical device manufacturing requires stringent quality control measures to comply with industry standards and regulations. SAP Business One can be integrated with quality management systems (QMS) to monitor production processes, manage non-conformances, maintain audit trails, and enforce quality control procedures.

-

Production Planning and Scheduling: SAP Business One can help manage production orders, work centers, and resource allocation, ensuring smooth production processes and timely delivery of products. By integrating with advanced planning and scheduling (APS) tools, manufacturers can optimize resource utilization and minimize production bottlenecks.

-

Traceability and Compliance: In the medical device industry, maintaining traceability and ensuring regulatory compliance are crucial. SAP Business One can track batch and serial numbers throughout the supply chain, ensuring full traceability of materials and products. Additionally, it can help maintain compliance with industry regulations such as FDA 21 CFR Part 11, ISO 13485, and EU Medical Device Regulation (MDR).

-

Document Management: Medical device manufacturers must manage a vast array of documents, including quality manuals, work instructions, and regulatory submissions. SAP Business One can integrate with document management systems (DMS) to store, organize, and manage these critical documents efficiently.

-

Customer Relationship Management (CRM): With a built-in CRM module, SAP Business One can help medical device manufacturers manage customer interactions, track sales opportunities, and maintain post-sales support, ensuring strong customer relationships.

Microsoft Dynamics 365 is a cloud-based enterprise resource planning (ERP) software solution that helps businesses streamline their operations, automate processes, and manage their data more efficiently. While it is not specifically designed for the medical device industry, it can be configured and customized to meet the unique needs of medical device manufacturers.

Here are some ways that Microsoft Dynamics 365 can be used as a medical device ERP:

-

Product Lifecycle Management (PLM): Microsoft Dynamics 365 can be used to manage the entire product lifecycle of medical devices, from design and development to manufacturing and distribution. It can track product specifications, design changes, regulatory compliance, and quality control.

-

Supply Chain Management (SCM): Medical device manufacturers can use Dynamics 365 to manage their supply chain and logistics operations, from ordering raw materials to delivering finished products to customers. This can help reduce costs, improve efficiency, and enhance customer satisfaction.

-

Quality Management: Microsoft Dynamics 365 can be used to manage quality control processes for medical devices, including compliance with regulatory standards such as ISO 13485 and FDA regulations. It can track non-conformance events, manage corrective and preventive actions, and generate quality metrics and reports.

-

Sales and Marketing: Dynamics 365 can be used to manage sales and marketing activities, including customer relationship management (CRM), lead tracking, and campaign management. Medical device manufacturers can use this to track customer interactions, manage sales pipelines, and generate sales forecasts.

-

Financial Management: Microsoft Dynamics 365 can be used to manage financial processes for medical device manufacturers, including accounts payable and receivable, general ledger, and financial reporting. This can help businesses track expenses, manage cash flow, and generate financial statements and reports.

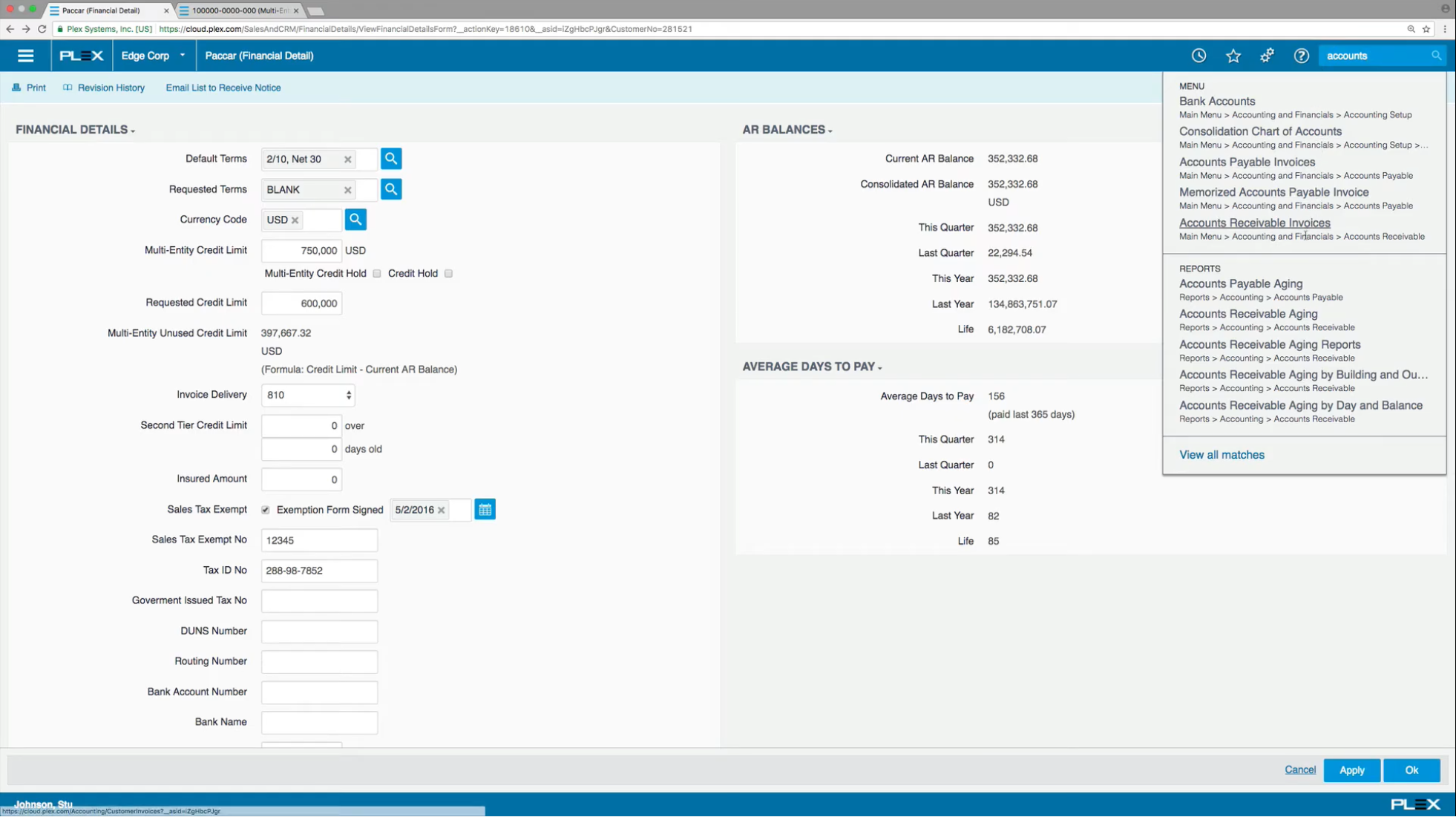

Plex Manufacturing Cloud is a cloud-based manufacturing software platform designed to help manufacturers manage their operations efficiently. This platform can be used in a variety of industries, including medical device manufacturing.

One of the key features of Plex Manufacturing Cloud is its ability to manage the entire manufacturing process, from raw materials procurement to finished product delivery. This can be especially important in medical device manufacturing, where strict regulatory requirements must be met at every stage of the process.

Here are some ways that Plex Manufacturing Cloud can be used as a medical device manufacturing software:

-

-

Quality Management: Quality control is a critical component of medical device manufacturing. The Plex platform provides tools for managing quality control processes, including inspection and testing, document control, and non-conformance management.

-

Compliance: Medical device manufacturers are subject to numerous regulations and standards, including ISO 13485, FDA 21 CFR Part 820, and EU Medical Device Regulation (MDR). Plex Manufacturing Cloud provides features that help manufacturers meet these regulatory requirements, including audit trails, traceability, and electronic signatures.

-

Inventory Management: Medical device manufacturers must maintain accurate inventory records to ensure that they have the necessary components and materials to manufacture products. Plex Manufacturing Cloud provides tools for managing inventory, including real-time inventory tracking, automated purchasing, and supplier management.

-

ERP Modules for Medical Devices

ERP systems allow companies in the medical devices industry to share data amongst different departments, eliminating information silos whilst enabling them to handle compliance and regulatory measures easily.

Accounting and Financials

Pharmaceutical ERP enables you to unite financials across multiple entities and geographies with tight integration to key pharmaceutical business processes.

Purchasing

Enable compliance and cost control with pharmaceutical ERP that provides approval matrixes, purchase requisitions, orders and control.

Production

Integrate with contract manufacturing organizations (CMO) or run production in house with pharmaceutical ERP that enables easy compliance and traceability.

Inventory Management

Monitor stock and inventory across multiple locations and perform real time valuations in pharmaceutical ERP software.

Quality Management

Modern pharmaceutical ERP gives you the power to control quality at all steps of your internal processes to ensure you can

Asset Management

Manage fixed assets within your pharmaceutical ERP solution and convert your R&D spend to assets on your balance sheet with pharmaceutical ERP.

Reporting and dashboards

Get one view of your pharmaceutical operation with inbuilt reporting and dashboards for your ERP solution.

Expenses Management

Automate expenses requisitions and approvals for your sales team or R&D team within your ERP system.

Sales management

Track & plan sales pipeline, score leads, prospects and forecast opportunities in real-time across territories, accounts and teams.

Customisation

Flexible ERP software that's built on an open and extensible foundation, allowing you to choose the features that suit your business needs.

Mobility

Access your ERP data at any time so you're more available to customers and take advantage of unexpected opportunities as they surface.

Updates and maintenance

Backed by the consistency of market-leading vendors, ERP software regularly updates to ensure an optimal user experience.

ERP for Medical Devices Industry FAQ

What is the Best Medical Devices ERP?

The best ERP software for medical devices can include solutions such as Microsoft Dynamics, Oracle, Netsuite, SAP & Infor. Selecting the best ERP system for your medical device company will largely depend on your size, specific system needs and various other factors.

What are the Key Features and Modules of the Best Medical Devices ERP?

ERP software for medical devices business includes all of the typical modules within almost all ERP systems including:

- Financial Management & Accounting

- Sales & Distribution

- Supply Chain

- Procurement

- Manufacturing & Production

- Human Resources

- Reporting & Analytics

Plant Maintenance - Asset Management

However, the best ERP solutions for medical devices also tend to include industry-specific modules and functionalities which include:

- FDA, MHRA compliance.

- Life sciences ISO certifications.

- Serialization

- CAD management and integration

- Variance and defect tracking and management

- Contract manufacturing organization (CMO) integration and portals.

- Lot traceability

- Product Configuration

- Manufacturing Execution Systems (MES)

- Bill of materials (BOM)

- CGMP

- Product Lifecycle Management (PLM)

- Traceability

- Batch Management

- Product recall management

- Recipe Management

- SOX Compliance

- Audit Trails

How much does ERP for medical devices cost?

Costs for ERP in the medical devices industry can range from $100,000 in Year 1 to several millions. Medical devices ERP costs are typically made up of software licensing, support and implementation.

Increasingly, medical devices companies are turning to Cloud ERP software solutions which are paid for on a subscription basis. Annual fees for Medical Devices Cloud ERP software for pharma can range anywhere from $500-2000 per user.

Support costs are typically a percentage of your software license cost and can fluctuate depending on the level of support your organization requires and how many hours of support you consume.

Medical devices ERP implementations are often the biggest up front cost and will depend on the medical devices ERP software you choose, your organizations size, the ERP project scope and your resourcing model.

What is the best ERP for pharmaceuticals? Best Pharma ERP Systems 2021

Review the best ERP systems for small, midsize and large medical devices companies including Infor, NetSuite, SAP Business One, Microsoft Dynamics 365 and more.

ERP Requirements Gathering (RFI, RFP) Template Excel

Start your pharmaceutical ERP evaluation process with our RFI & RFP Excel template for the pharma & biotech industry.

ERP Project Budget Calculator Template

Calculate the costs of your medical devices ERP project with our prebuilt budget calculator.

Start your ERP journey with ERP Research

-

Build An ERP Business Case 2-3 weeksA solid business case is a foundation you need if you are going to persuade your organization to consider enterprise resource planning (ERP) implementation. Download Business Case Template

-

Compare ERP Vendors 2-3 weeksIt’s critical to understand which ERP vendor is right for your business. Before you decide on the vendor for your company, take a look at our solution pages to find out which vendor would be best. Compare ERP Vendors

-

Get Pricing Estimates 1-2 weeksOur exclusive process removes all the salesmen from the equation and gets you real pricing estimates from every qualified vendor. Contact Us For Pricing

-

Organize A Solution Demo 1-2 weeksDuring a demo, you will learn about how large corporations are making use of ERP software and how they are improving their business practices. Book A Demo

-

Build ERP Requirements 3-4 weeksIf you're looking to buy an Enterprise Resource Planning (ERP) system or upgrade your internal systems you will need a clear definition of all the functions, features and capabilities that you expect. You can approach this challenge by building what's called an ERP requirements document. Download ERP Requirements Template

-

Shortlist 4-8 Vendors 1 weekOne of the most important phases in the ERP project lifecycle is selecting the right software vendor. Ideally, you should shortlist 4-8 vendors - based on their credentials and your requirements. Contact Us To Shortlist Vendors

Find & Compare ERP Software for the Medical Devices Industry

Use our free tool to find and compare the market leading ERP software and solutions for medical devices companies. See how ERP system solutions including NetSuite, Epicor, Infor & SAP Business One stack up against the competition.

.png?width=278&name=sap-s-4hana-logo%20(2).png)