Navigating the complex landscape of Engineer-to-Order (ETO) manufacturing demands precision, flexibility, and efficiency. This is where ETO ERP (Enterprise Resource Planning) software becomes not just a tool, but a game-changer for businesses striving to meet the unique challenges of custom product engineering and manufacturing. In this comprehensive blog post, we delve deep into the world of ETO ERP solutions, exploring their essence, the unparalleled benefits they offer to ETO manufacturers, the investment involved, and the critical steps for selecting the right ETO ERP system to fit your business's unique needs.

Contents:

What is ETO ERP?

ETO ERP Software

Benefits of ETO ERP

Costs of ETO ERP

How to select an ETO ERP

What is ETO ERP?

Engineer-to-Order (ETO) ERP (Enterprise Resource Planning) software are a specialized category of ERP systems designed to accommodate the unique operational needs of businesses that provide custom-engineered products and solutions.

Unlike standard products that can be mass-produced and stocked, ETO products are typically designed, engineered, and manufactured after receiving specific customer orders, making each product unique.

This process involves complex project management, engineering design, and production planning challenges that ETO ERP software aims to address. Below is a detailed explanation of ETO ERP software, highlighting its features, benefits, and how it differs from other types of ERP systems.

Key Features of ETO ERP Software

Project Management:

ETO ERP systems include robust project management tools to plan, execute, and monitor all aspects of the engineering and manufacturing process. This feature helps in scheduling resources, tracking progress, and ensuring projects are completed on time and within budget.

Customer Requirement Management:

These systems offer functionalities to capture and manage detailed customer requirements and specifications. This is crucial for custom engineering projects where success depends on meeting specific customer needs.

Design and Engineering Integration:

ETO ERP software often integrates with CAD (Computer-Aided Design) and other engineering tools to facilitate seamless data flow between design and manufacturing teams. This integration helps in reducing errors and improving efficiency by ensuring that the manufacturing team has direct access to the latest designs and specifications.

Cost Estimation and Quoting:

Accurate cost estimation is critical in ETO environments. The software provides tools to estimate costs based on materials, labor, and overheads more accurately and generate detailed quotes for customers.

Material Requirement Planning (MRP):

Given the custom nature of ETO products, managing inventory and purchasing materials can be complex. ETO ERP systems include advanced MRP features to manage just-in-time inventory, reduce waste, and ensure materials are available when needed.

Manufacturing Execution System (MES):

This feature oversees the production process, from work order creation to the shop floor control, ensuring that manufacturing operations align with project requirements and timelines.

Quality Management:

Quality control mechanisms are built into ETO ERP systems to ensure that the products meet the required standards and specifications. These mechanisms include tracking defects, managing inspections, and integrating customer feedback into the product design and manufacturing process.

Engineer-to-order-ERP Software

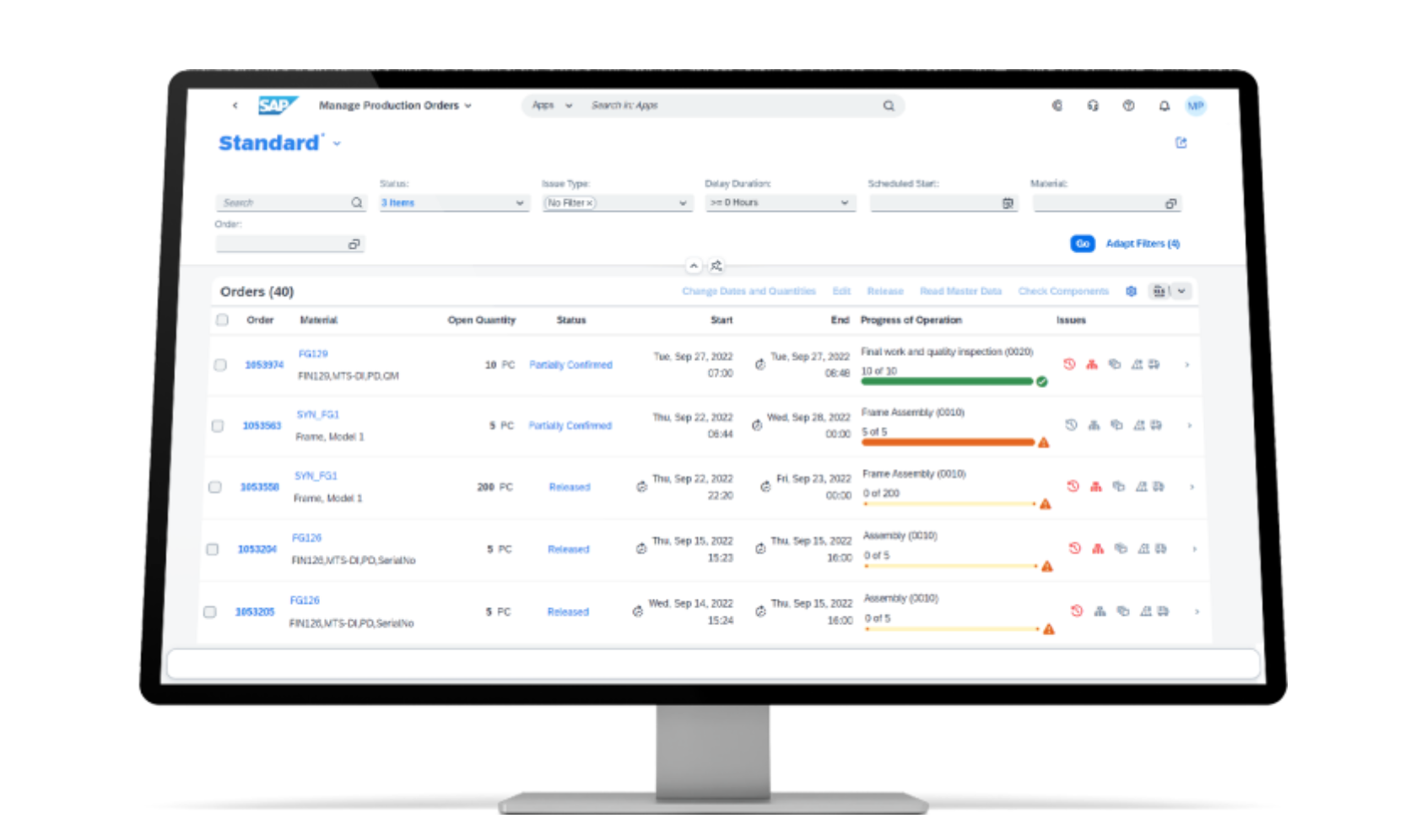

SAP S/4HANA

SAP's flagship ERP system, S/4HANA, offers advanced capabilities that can be tailored to ETO manufacturing. Its strengths include real-time analytics, project management, and integration with business networks for comprehensive supply chain management.

Best for: Medium to Large organisations with medium to high complexity.

Pricing: $500K+ first year costs

Epicor ERP

Offers robust capabilities for ETO manufacturers, including project management, material requirements planning, and integration with engineering design tools. Epicor is known for its flexibility and industry-specific features that cater to the complex needs of ETO companies.

Best for: Small to marge organisations with low to medium complexity.

Pricing: $100K+ first year costs

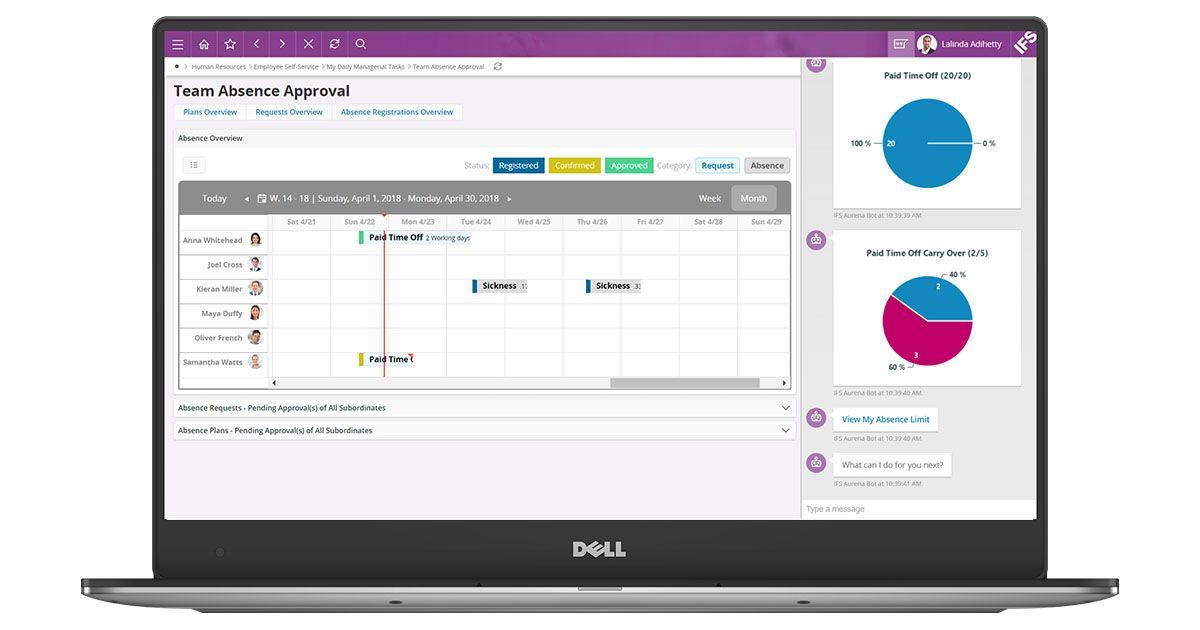

IFS Applications

IFS provides a comprehensive ERP solution with strong project and resource management features, making it suitable for ETO and project-based industries. Its ability to handle complex manufacturing processes and integrate with various CAD tools makes it a favored choice for ETO businesses.

Best for: Medium to Large organisations with medium to high complexity.

Pricing: $300K+ first year costs

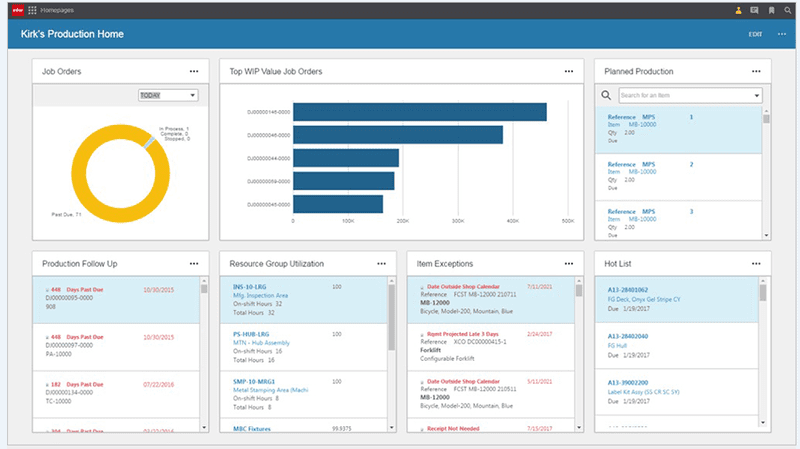

Infor CloudSuite Industrial (SyteLine)

Infor's CloudSuite Industrial is tailored for complex manufacturing environments, including ETO. It offers features such as advanced planning and scheduling, project management, and CAD integration to support the entire ETO lifecycle from design to delivery.

Best for: Small to Marge organisations with medium complexity.

Pricing: $150K+ first year costs

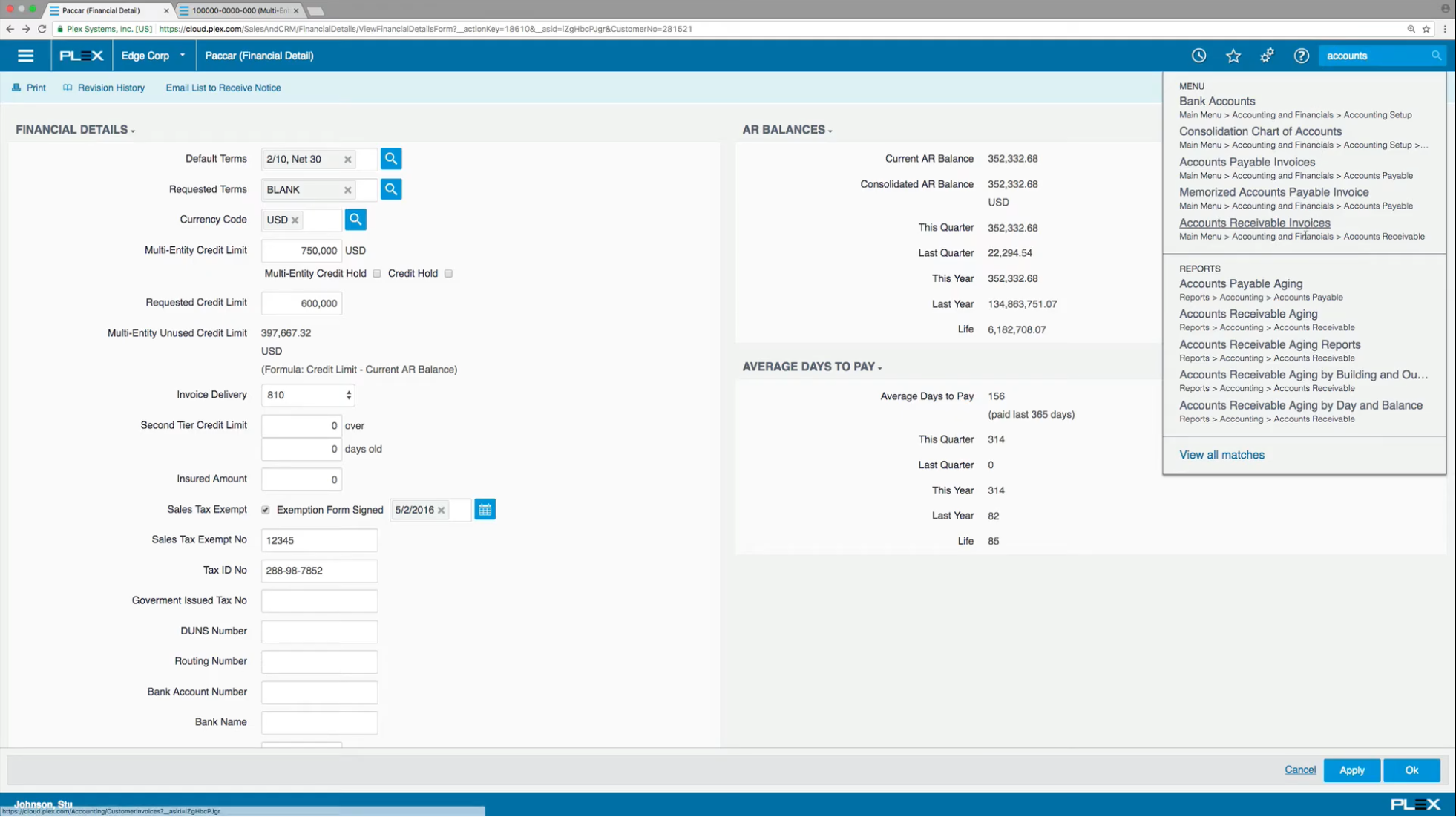

Plex Manufacturing Cloud

Plex offers cloud-based ERP solutions that support complex manufacturing processes, including ETO. Its strengths lie in real-time operations management, quality control, and integration with manufacturing execution systems (MES).

Best for: Small to Medium organisations with medium complexity.

Pricing: $200K+ first year costs

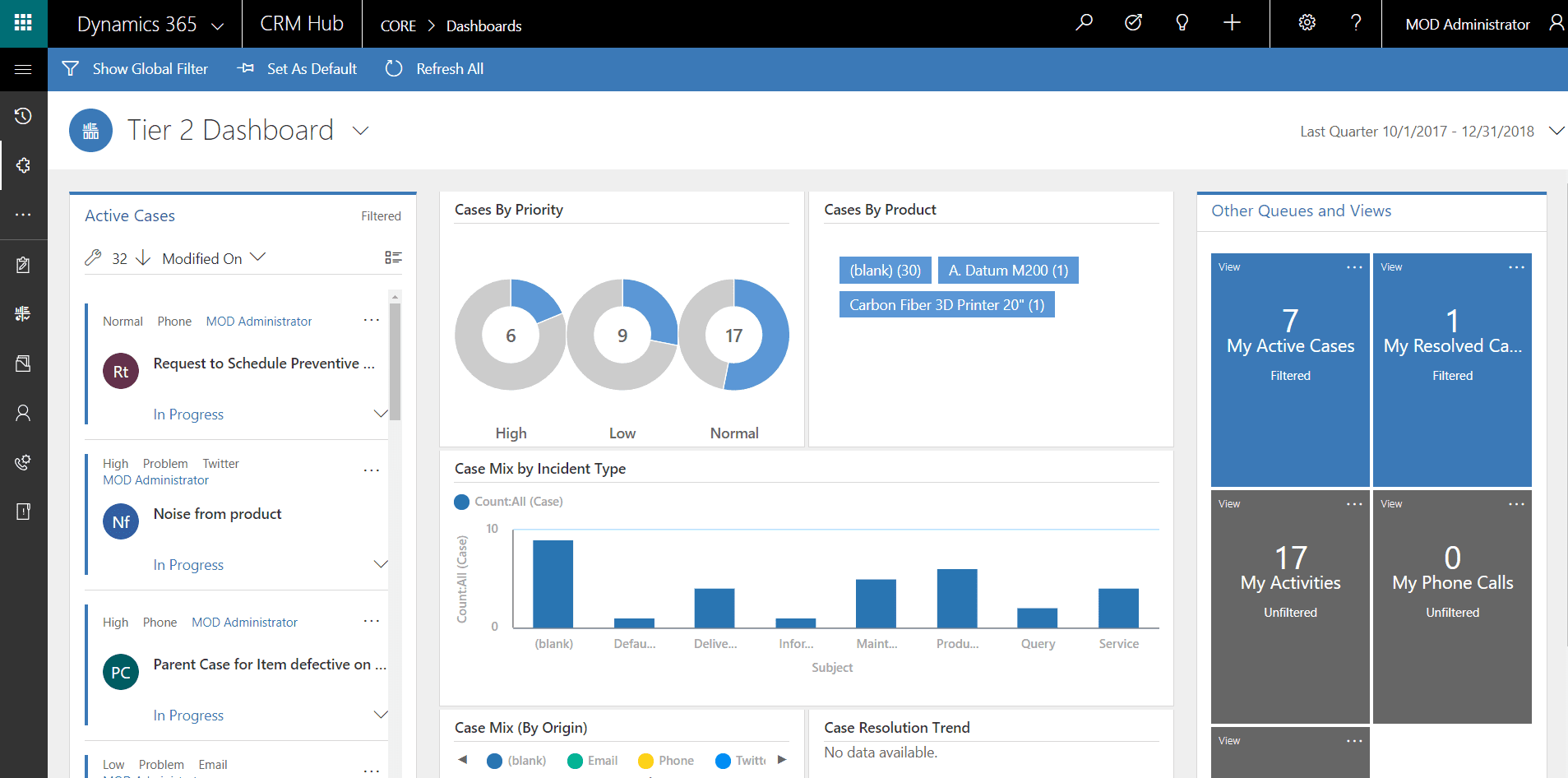

Microsoft Dynamics 365

Dynamics 365 provides modular ERP and CRM solutions that can be customized for ETO manufacturing. Its unified platform supports project service automation, supply chain management, and sales and marketing integration.

Best for: Small to Medium organisations with medium to high complexity.

Pricing: $500K+ first year costs

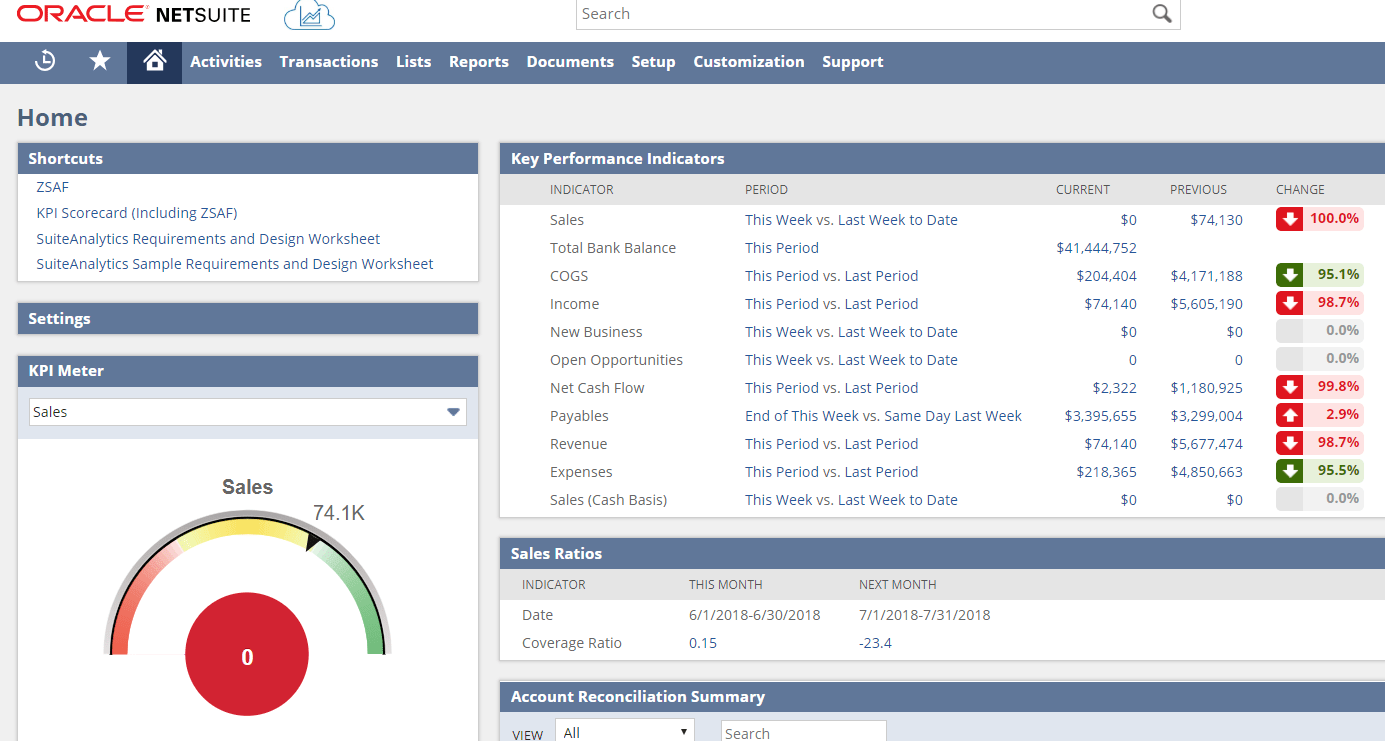

Oracle NetSuite

NetSuite's cloud ERP solutions offer comprehensive functionalities for project-based businesses, including ETO manufacturers. Features such as project management, procurement, and financials are integrated into a single platform to support the entire business lifecycle.

Best for: Small to Medium organisations with low complexity.

Pricing: $150K+ first year costs

Benefits of ETO ERP

ETO ERP software brings a host of benefits to businesses involved in engineer-to-order manufacturing, offering sophisticated tools and features designed to tackle the unique challenges of custom product development and production. Here's an expanded look at the key benefits of ETO ERP software:

Enhanced Project Visibility

ETO ERP software provides a unified platform that aggregates data from across all stages of a project, from initial customer inquiry through design, production, and delivery. This integration offers real-time visibility into every aspect of the project, including progress tracking, resource utilization, and milestone achievement. Managers can access dashboards and reports that highlight critical information, allowing them to identify issues early, adjust plans dynamically, and communicate effectively with stakeholders. This level of visibility is crucial for managing the complexities of ETO projects, where changes are frequent and coordination is essential.

Improved Efficiency

Automation is at the heart of ETO ERP systems, streamlining processes that traditionally require manual intervention. By automating tasks such as bill of materials creation, work order scheduling, and document management, ETO ERP software significantly reduces the time and effort involved in managing custom projects. Integration capabilities further enhance efficiency by ensuring seamless data flow between different departments and software tools, such as CAD systems and production management platforms. This not only speeds up the design-to-delivery cycle but also minimizes errors and inconsistencies that can arise from manual data entry or disjointed systems.

Cost Control

One of the most critical aspects of ETO manufacturing is the ability to accurately estimate and control project costs. ETO ERP systems come equipped with sophisticated costing and budgeting tools that provide detailed insights into the financial aspects of each project. These tools allow for precise estimation of material, labor, and overhead costs, and they enable ongoing monitoring of expenditures against the budget. By providing a clear picture of financial performance, ETO ERP software helps businesses identify cost overruns early, adjust project scopes or processes to stay within budget, and ensure the profitability of custom projects.

Customer Satisfaction

Meeting customer expectations in terms of product quality, customization, and delivery timelines is paramount in ETO manufacturing. ETO ERP software supports these goals through comprehensive customer requirement management features, which ensure that customer specifications are accurately captured and communicated throughout the organization. Additionally, project management and scheduling tools help guarantee that projects are completed on time. By fostering a collaborative environment, ETO ERP systems also enable businesses to keep customers informed about project progress and involve them in key decisions, enhancing the overall customer experience. The ability to consistently meet or exceed customer expectations leads to higher satisfaction levels, repeat business, and positive referrals.

Cost of ETO ERP

The costs associated with Engineer-to-Order (ETO) ERP software can be significant and vary widely depending on several factors, including the complexity of the solution, the size of the organization, deployment model, customization requirements, and additional services such as training and support. Understanding these costs is crucial for businesses considering the adoption of an ETO ERP system. Here’s a breakdown of the potential costs involved:

Software Licensing or Subscription Fees

Perpetual Licensing: For on-premises deployments, companies may pay a one-time licensing fee based on the number of users or the size of the organization. This model often involves higher upfront costs but can be cost-effective over a long period.

Subscription Model: Cloud-based ETO ERP solutions typically operate on a subscription basis, with fees charged monthly or annually per user. This model offers lower initial costs and includes updates and maintenance, making it a popular choice for small to medium-sized businesses.

Implementation Costs

Customization: ETO ERP systems often require significant customization to fit the specific processes and workflows of a company. The extent of these customizations can greatly influence the overall implementation cost.

Integration: Integrating the ERP system with existing systems (e.g., CRM, CAD software) is usually necessary and can add to the cost, depending on the complexity of the integration.

Data Migration: Moving data from old systems to the new ERP system needs careful planning and execution, which incurs costs, especially if the data needs to be cleaned or transformed.

Training and Support

Training: Proper training is essential for ensuring that staff can use the ERP system effectively. Training costs can vary based on the number of users, the complexity of the system, and whether it's conducted on-site or online.

Support: Ongoing support and maintenance agreements are critical for resolving any issues that arise and ensuring the system is updated. These costs are typically annual or monthly fees and can be a significant part of the total cost of ownership.

Hardware and Infrastructure

On-Premises Deployment: For companies choosing an on-premises deployment, there will be significant investments in the necessary hardware and IT infrastructure.

Cloud-Based Deployment: While cloud deployments reduce the need for extensive on-site hardware, there may still be costs associated with ensuring adequate internet bandwidth and security measures.

Additional Costs

Upgrades: While subscription models usually include updates, upgrading an on-premises system can involve substantial costs for the new software version and the implementation process.

Consulting Fees: Many companies hire external consultants to help with the selection, implementation, and customization of an ETO ERP system, which adds to the overall cost.

How to select an ETO ERP

Selecting the right Engineer-to-Order (ETO) ERP system is a critical decision that can significantly impact the operational efficiency, flexibility, and competitiveness of a business specializing in custom products. The process involves thorough research, evaluation, and a strategic approach to ensure the chosen system meets the unique needs of an ETO manufacturing environment. Here’s a comprehensive guide on how to select an ETO ERP system:

Define Your Business Requirements

Identify Key Processes: Start by mapping out your core business processes, including project management, design and engineering, production, and customer management. Understanding these processes is crucial for identifying the specific functionalities you need in an ERP system.

Determine Must-Have Features: Based on your business processes, identify the essential features your ETO ERP must have. This may include project management tools, CAD integration, customizable workflows, real-time reporting, and more.

Consider Scalability: The ERP system should be able to grow with your business, accommodating new processes, additional users, and increased complexity without significant disruptions or upgrades.

Research and Shortlist Vendors

Market Research: Conduct thorough research to identify ERP vendors with specific experience and capabilities in the ETO manufacturing sector. Look for case studies, customer reviews, and industry recommendations.

Vendor Shortlisting: Based on your research, create a shortlist of vendors whose products match your identified requirements. Consider both industry giants and niche providers, as they may offer different advantages.

Evaluate the ERP Systems

Request Demonstrations: Arrange for detailed demonstrations with each shortlisted vendor to see their ERP systems in action. Ensure the demos focus on your key processes and requirements.

Check References and Case Studies: Ask for references from businesses similar to yours in size and industry. Inquire about their experiences, focusing on implementation, customization, support, and the system's impact on their operations.

Assess Customization and Integration Capabilities: Understand how easily the ERP can be customized to fit your specific processes and how well it integrates with existing systems or third-party applications you rely on.

Consider the Vendor's Industry Expertise: The vendor should have a deep understanding of ETO manufacturing challenges and be able to provide insights and solutions that align with industry best practices.

Analyze Total Cost of Ownership (TCO)

Evaluate Pricing Models: Look beyond the initial cost to understand the total cost of ownership, including customization, implementation, training, support, and upgrades.

Budget for Hidden Costs: Be aware of potential hidden costs such as additional hardware, third-party integrations, or data migration expenses.

Plan for Implementation and Support

Implementation Strategy: Discuss and plan the implementation process with the vendor, including timelines, milestones, and resource allocation. A phased approach can help minimize disruptions to your operations.

Training and Support: Ensure the vendor offers comprehensive training for your team and assess the level of ongoing support available, including response times and support channels.

Make a Decision

Gather a Decision-Making Team: Include stakeholders from various departments such as IT, engineering, production, and finance to ensure all perspectives are considered.

Review and Compare Proposals: Carefully review and compare the final proposals from each vendor based on functionality, cost, support, and vendor reliability.

Consider Future Needs: Choose a system that not only meets your current requirements but also has the potential to accommodate future business growth and changes.

Prepare for Change Management

Develop a Change Management Plan: Successful ERP implementation requires buy-in from all levels of the organization. Prepare a plan to manage the transition, addressing potential resistance and ensuring clear communication about the benefits and changes the ERP system will bring.